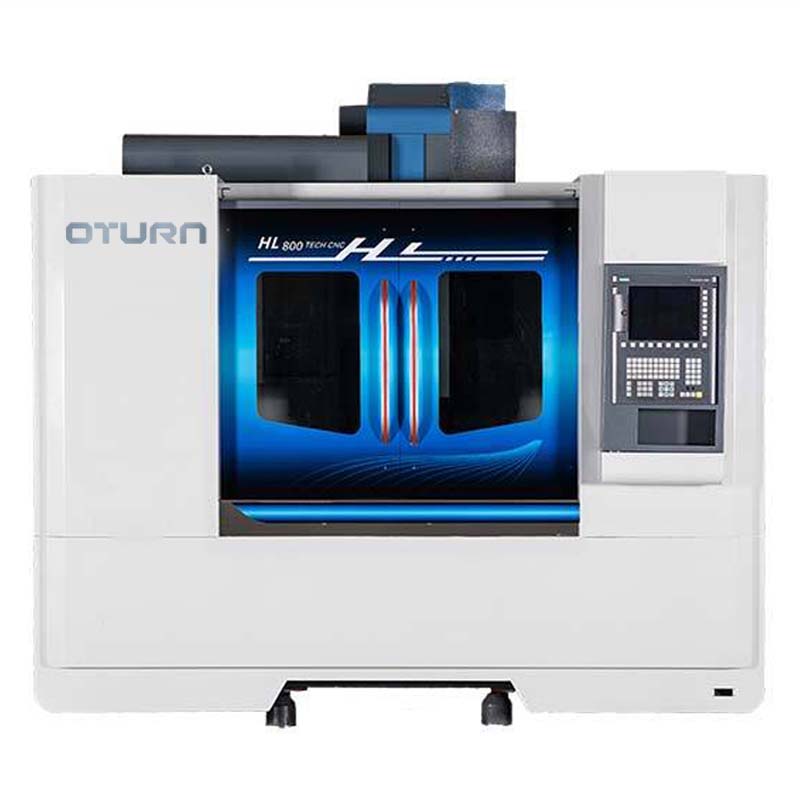

Top China Manufacturer of Industrial Valve Machining Machines

Our Industrial Valve Machining Machine is designed for manufacturers in China who need precision and efficiency. I’ve seen how crucial it is for businesses to maintain high-quality standards, and that’s exactly what our machine delivers. With advanced technology, it enables precise machining of various valve components, ensuring perfect fits and reliable performance. This machine is not just about functionality; it’s built with durability in mind, with materials that withstand heavy use. I know that minimizing downtime is essential for operations, and our machine helps achieve that with its user-friendly interface and low maintenance requirements. When you choose our Industrial Valve Machining Machine, you’re investing in a solution that increases production efficiency and ensures top-notch quality. It’s perfect for manufacturers looking to enhance their machining capabilities. Let’s elevate your production line together, making quality and precision your competitive edge in the market.

Industrial Valve Machining Machine Manufacturer Guarantees Peak Performance

In the competitive landscape of industrial manufacturing, the need for precision and reliability in valve machining is paramount. A leading manufacturer in this sector understands that peak performance not only hinges on advanced technology but also on a commitment to quality and continuous improvement. By leveraging state-of-the-art machinery and skilled technicians, the company ensures that each valve is produced to exacting standards, capable of withstanding the rigorous demands of various industries. Global procurement agents should look for manufacturers that prioritize innovation and sustainability. This includes the incorporation of cutting-edge machining techniques that optimize efficiency while minimizing waste. The emphasis on resource-efficient operations not only helps in reducing costs but also aligns with global standards for environmental responsibility. By choosing a supplier who adopts such practices, buyers can be confident they are making a choice that supports both their operational needs and broader sustainability goals. Moreover, strong after-sales support and expertise in customization allow for tailored solutions that meet specific operational requirements. Collaborative partnerships with manufacturers can lead to enhanced performance in applications ranging from oil and gas to water treatment systems. This holistic approach to valve machining ensures that procurement decisions lead to durable and high-performance products, essential for maintaining competitive advantage in today’s dynamic market.

Industrial Valve Machining Machine Manufacturer Guarantees Peak Performance

| Feature | Specification | Benefits |

|---|---|---|

| Precision Machining | Tolerance: ±0.01 mm | Enhances product quality and reduces wastage |

| High Speed Operation | Max Speed: 12000 RPM | Increases production efficiency |

| Robust Build Quality | Material: Hardened Steel | Ensures durability and longevity |

| User-Friendly Interface | Touchscreen Control | Simplifies operation and reduces training time |

| Energy Efficiency | Power Consumption: 5 kW | Reduces operational costs |

Related Products