Horizontal 5-Axis CNC Machining Center TKG1600

Features

I. High Rigidity Structure

The machine adopts a low center of gravity, integral body design, ensuring structural stability. Combined with large-size linear guides and multi-slider supports, it significantly improves cutting rigidity and dynamic stability.

The X/Y/Z axes utilize high-lead ball screws, achieving high-speed positioning and sustained precision.

II. High-Speed and High-Efficiency Motion Performance

The XYZ axis rapid traverse speed reaches up to 60 m/min, with tool changes taking only 5 seconds.

The servo-driven tool magazine system can pre-select the next tool during machining, enabling direct engagement without waiting and shortening non-cutting time.

During spindle tool changes, the fourth and fifth axes are synchronously pre-positioned, allowing machining to continue immediately after the tool change, achieving faster positioning and shorter machining cycles.

High-speed feed and intelligent tool changing work together to significantly improve the overall machine cycle efficiency.

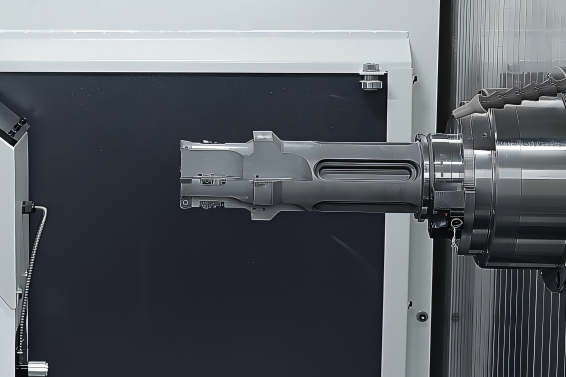

III. Dual-Support Spindle System

The machine tool is equipped with an HSK-A100 dual-contact spindle structure, with a maximum speed of 10,000 rpm and a maximum torque of 320 N·m.

The integrated spindle structure effectively suppresses thermal deformation and vibration, ensuring stable accuracy and excellent surface finish at high speeds.

The dual-contact design provides excellent rigidity during heavy cutting, reducing machining time and extending spindle and tool life.

A built-in circulating thermostatic control system on the outer ring of the spindle continuously dissipates heat, preventing thermal drift and maintaining high precision.

IV. Intelligent Cooling System

High-pressure coolant is precisely sprayed from the spindle's central through-hole to the tool's cutting edge, achieving efficient cooling and rapid chip removal.

The system features pressure-sensing adjustment, automatically adjusting the pressure (programmable range 30–70 kg/cm²) based on tool and path changes, maintaining a constant cutting point pressure.

Combined with the spindle's thermostatic circulation system, the entire machine remains accurate and stable even under prolonged high-speed operation, significantly extending the lifespan of both tools and the spindle.

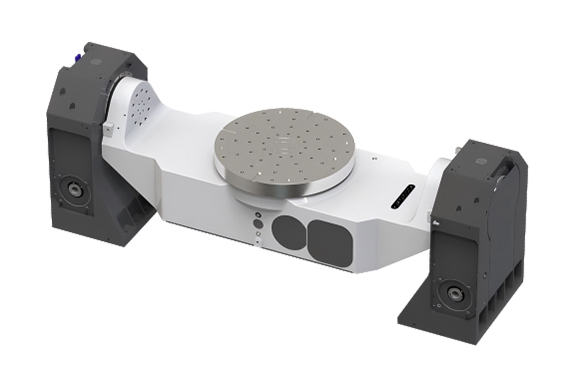

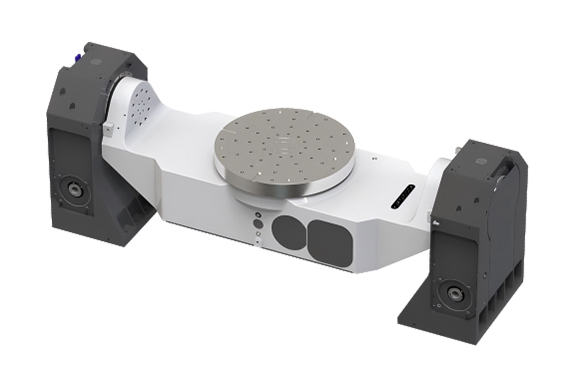

V. Large-Stroke Five-Axis Simultaneous Structure

Employing a low-table, double-swivel-head design, it provides ample machining space: maximum workpiece rotation diameter 1600 mm, machining height 550 mm, tilt range -140° to +20°, and a maximum table load capacity of 1000 kg.

The A-axis uses a dual-motor, dual-brake system, providing powerful braking torque, precise positioning, and effectively counteracting the counter-torque from heavy cutting.

The C-axis is equipped with a high-precision roller worm gear drive structure, achieving zero backlash and high load capacity, comprehensively ensuring the accuracy of five-axis synchronous machining.

VI. Automation and Reliability

The worktable integrates a 12-channel rotary joint with pneumatic-hydraulic channels, enabling automated functions such as automatic clamping, automatic door control, automatic tool breakage detection, automatic spray cooling, and chip removal.

The spindle features an 8/12-channel rotary joint system to ensure stable hydraulic pressure in the fixture during machining.

The machine tool also has reserved interfaces for airtightness testing and customization, facilitating future intelligent manufacturing and unmanned upgrades.

This series of automated configurations enables the machine tool to operate continuously 24/7, ensuring stable and efficient production.

VII. High-Speed Transmission System

The entire axis utilizes a combination of large-diameter ball screws and roller linear guides, achieving high-speed movement and superior rigidity.

The servo motor direct-drive structure eliminates transmission backlash, resulting in faster response and more accurate positioning.

Excellent acceleration and deceleration performance significantly reduces non-cutting time, leading to higher production speed and processing efficiency.

Technical Specifications

|

Linear Axis Parameters |

||

|

1 |

X/Y/Z-axis stroke range(mm) |

1600/1100/850 |

|

Rotation Axis Parameters |

||

|

1 |

A-axis travel |

-140°~+20° |

|

2 |

C-axis travel |

360° |

|

Feed |

||

|

1 |

Rapid Traverse:m/min |

60 |

|

2 |

Cutting Feed Rate:m/min |

20 |

|

3 |

Rapid Traverse Acceleration:g |

1G |

|

Machine Parameters |

||

|

1 |

Total height(mm) |

4560 |

|

2 |

Footprint(mm) |

3,757×3,371 |

|

3 |

Machine Net Weight:t |

22 |

|

Worktable Parameters |

||

|

1 |

Worktable Size:mm |

φ800 |

|

2 |

Workpiece Height Range:mm |

550 |

|

3 |

Maxi. Swing Diameter:mm |

1600 |

|

4 |

Max.Table Load Capacity:kg |

1000 |

|

Tool Magazine Parameters |

||

|

1 |

Tool Magazine Capacity:tools |

60 |

|

2 |

T-T Tool Change Time:s |

5 |

|

3 |

Max. Tool Length:mm |

550 |

|

4 |

Max. Tool Weight:kg |

25 |

|

Basic Configuration |

||

|

1 |

5-Axis, 4-Simultaneous Contouring · Tool Center Point Control |

√ |

|

2 |

Through-Spindle Coolant |

(50kg/cm) |

|

3 |

A/C-Axis Hydrauic Brake |

√ |

|

4 |

Spindle |

10,000 rpm, HSK-A100 Taper |

|

5 |

A/C-Axis Drive System |

Precision Rolling Worm Drive |

|

6 |

A/C-Axis Braking System |

Hydraulic Brake System |

|

7 |

Spindle Cooling System |

√ |

|

8 |

Chip Conveyor System |

√ |

|

9 |

Hydraulic Power Unit |

√ |

|

10 |

Tool Management Function |

√ |

|

11 |

Manual Pulse Generator |

√ |

|

System |

||

|

1 |

SINUMERIK 828D |

√ |

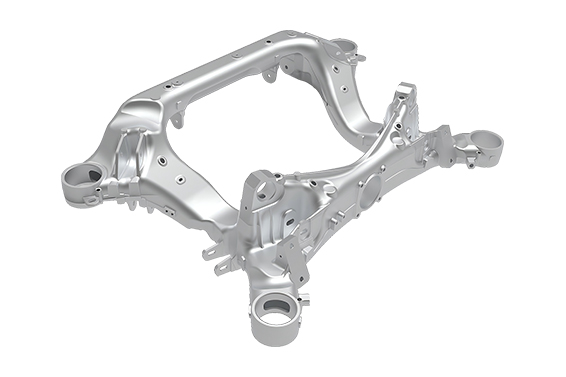

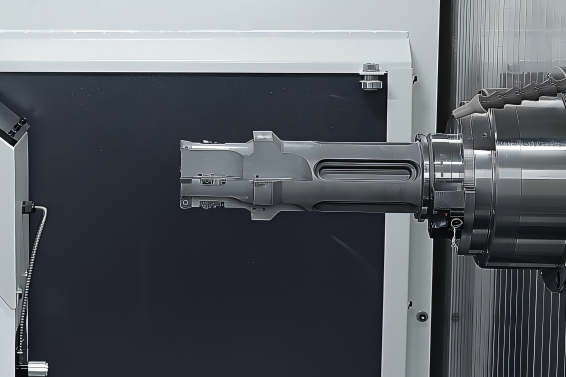

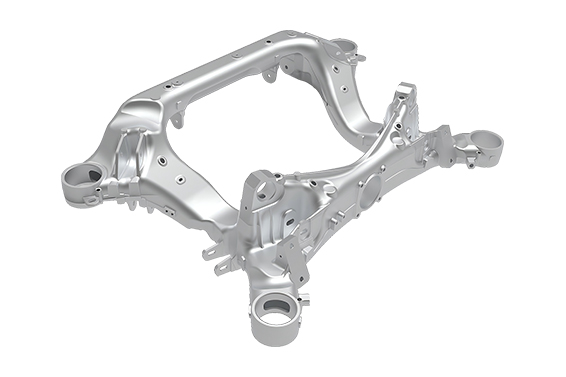

Processing Example

I. High Rigidity Structure

The machine adopts a low center of gravity, integral body design, ensuring structural stability. Combined with large-size linear guides and multi-slider supports, it significantly improves cutting rigidity and dynamic stability.

The X/Y/Z axes utilize high-lead ball screws, achieving high-speed positioning and sustained precision.

II. High-Speed and High-Efficiency Motion Performance

The XYZ axis rapid traverse speed reaches up to 60 m/min, with tool changes taking only 5 seconds.

The servo-driven tool magazine system can pre-select the next tool during machining, enabling direct engagement without waiting and shortening non-cutting time.

During spindle tool changes, the fourth and fifth axes are synchronously pre-positioned, allowing machining to continue immediately after the tool change, achieving faster positioning and shorter machining cycles.

High-speed feed and intelligent tool changing work together to significantly improve the overall machine cycle efficiency.

III. Dual-Support Spindle System

The machine tool is equipped with an HSK-A100 dual-contact spindle structure, with a maximum speed of 10,000 rpm and a maximum torque of 320 N·m.

The integrated spindle structure effectively suppresses thermal deformation and vibration, ensuring stable accuracy and excellent surface finish at high speeds.

The dual-contact design provides excellent rigidity during heavy cutting, reducing machining time and extending spindle and tool life.

A built-in circulating thermostatic control system on the outer ring of the spindle continuously dissipates heat, preventing thermal drift and maintaining high precision.

IV. Intelligent Cooling System

High-pressure coolant is precisely sprayed from the spindle’s central through-hole to the tool’s cutting edge, achieving efficient cooling and rapid chip removal.

The system features pressure-sensing adjustment, automatically adjusting the pressure (programmable range 30–70 kg/cm²) based on tool and path changes, maintaining a constant cutting point pressure.

Combined with the spindle’s thermostatic circulation system, the entire machine remains accurate and stable even under prolonged high-speed operation, significantly extending the lifespan of both tools and the spindle.

V. Large-Stroke Five-Axis Simultaneous Structure

Employing a low-table, double-swivel-head design, it provides ample machining space: maximum workpiece rotation diameter 1600 mm, machining height 550 mm, tilt range -140° to +20°, and a maximum table load capacity of 1000 kg.

The A-axis uses a dual-motor, dual-brake system, providing powerful braking torque, precise positioning, and effectively counteracting the counter-torque from heavy cutting.

The C-axis is equipped with a high-precision roller worm gear drive structure, achieving zero backlash and high load capacity, comprehensively ensuring the accuracy of five-axis synchronous machining.

VI. Automation and Reliability

The worktable integrates a 12-channel rotary joint with pneumatic-hydraulic channels, enabling automated functions such as automatic clamping, automatic door control, automatic tool breakage detection, automatic spray cooling, and chip removal.

The spindle features an 8/12-channel rotary joint system to ensure stable hydraulic pressure in the fixture during machining.

The machine tool also has reserved interfaces for airtightness testing and customization, facilitating future intelligent manufacturing and unmanned upgrades.

This series of automated configurations enables the machine tool to operate continuously 24/7, ensuring stable and efficient production.

VII. High-Speed Transmission System

The entire axis utilizes a combination of large-diameter ball screws and roller linear guides, achieving high-speed movement and superior rigidity.

The servo motor direct-drive structure eliminates transmission backlash, resulting in faster response and more accurate positioning.

Excellent acceleration and deceleration performance significantly reduces non-cutting time, leading to higher production speed and processing efficiency.

|

Linear Axis Parameters |

||

|

1 |

X/Y/Z-axis stroke range(mm) |

1600/1100/850 |

|

Rotation Axis Parameters |

||

|

1 |

A-axis travel |

-140°~+20° |

|

2 |

C-axis travel |

360° |

|

Feed |

||

|

1 |

Rapid Traverse:m/min |

60 |

|

2 |

Cutting Feed Rate:m/min |

20 |

|

3 |

Rapid Traverse Acceleration:g |

1G |

|

Machine Parameters |

||

|

1 |

Total height(mm) |

4560 |

|

2 |

Footprint(mm) |

3,757×3,371 |

|

3 |

Machine Net Weight:t |

22 |

|

Worktable Parameters |

||

|

1 |

Worktable Size:mm |

φ800 |

|

2 |

Workpiece Height Range:mm |

550 |

|

3 |

Maxi. Swing Diameter:mm |

1600 |

|

4 |

Max.Table Load Capacity:kg |

1000 |

|

Tool Magazine Parameters |

||

|

1 |

Tool Magazine Capacity:tools |

60 |

|

2 |

T-T Tool Change Time:s |

5 |

|

3 |

Max. Tool Length:mm |

550 |

|

4 |

Max. Tool Weight:kg |

25 |

|

Basic Configuration |

||

|

1 |

5-Axis, 4-Simultaneous Contouring · Tool Center Point Control |

√ |

|

2 |

Through-Spindle Coolant |

(50kg/cm) |

|

3 |

A/C-Axis Hydrauic Brake |

√ |

|

4 |

Spindle |

10,000 rpm, HSK-A100 Taper |

|

5 |

A/C-Axis Drive System |

Precision Rolling Worm Drive |

|

6 |

A/C-Axis Braking System |

Hydraulic Brake System |

|

7 |

Spindle Cooling System |

√ |

|

8 |

Chip Conveyor System |

√ |

|

9 |

Hydraulic Power Unit |

√ |

|

10 |

Tool Management Function |

√ |

|

11 |

Manual Pulse Generator |

√ |

|

System |

||

|

1 |

SINUMERIK 828D |

√ |