Gantry Milling Machine Manufacturer in China: Quality & Precision Tools

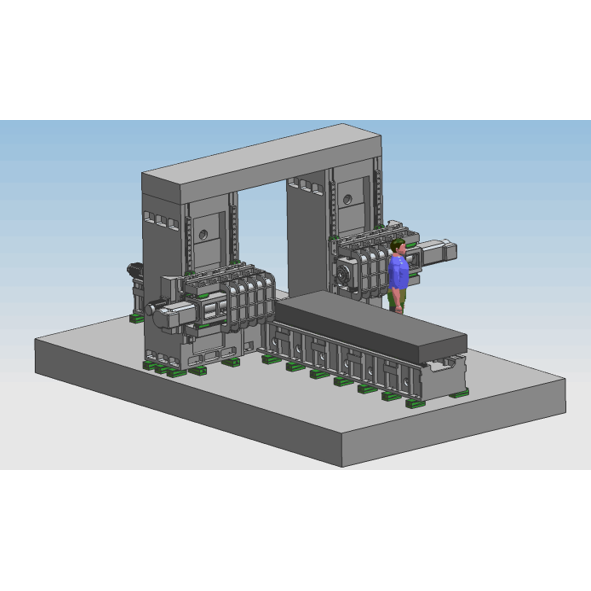

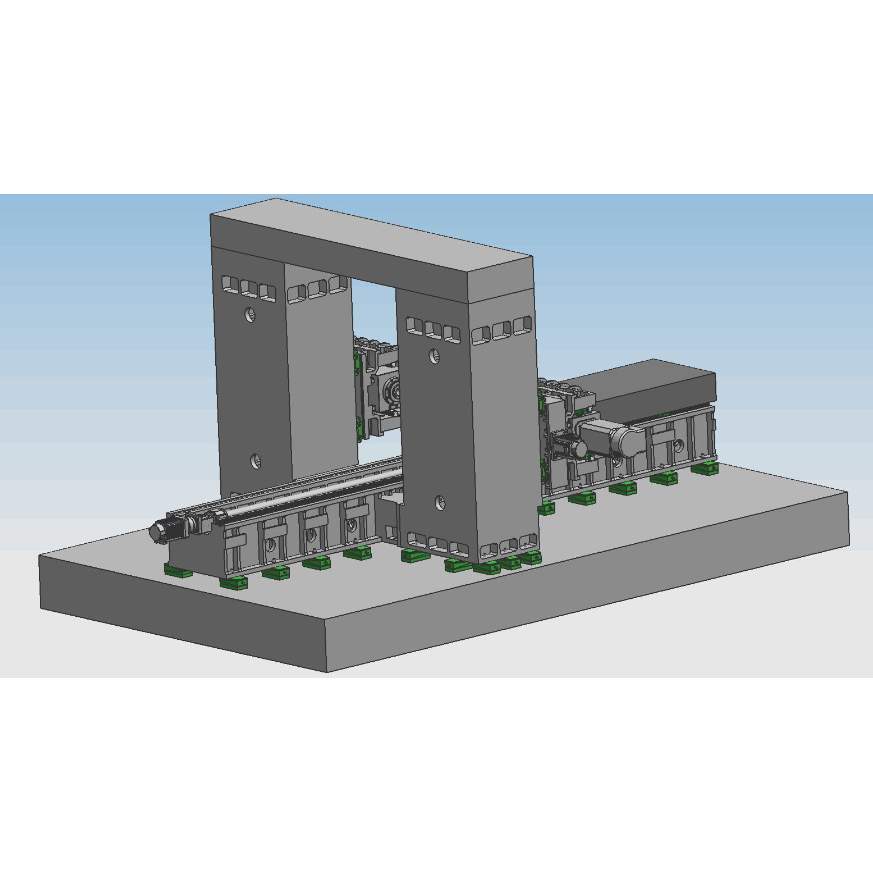

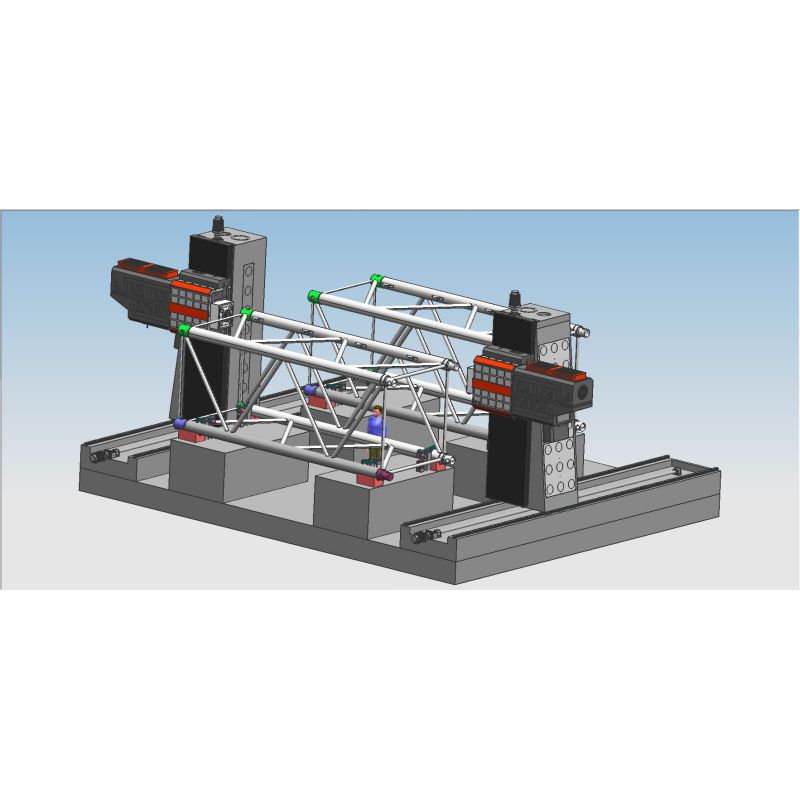

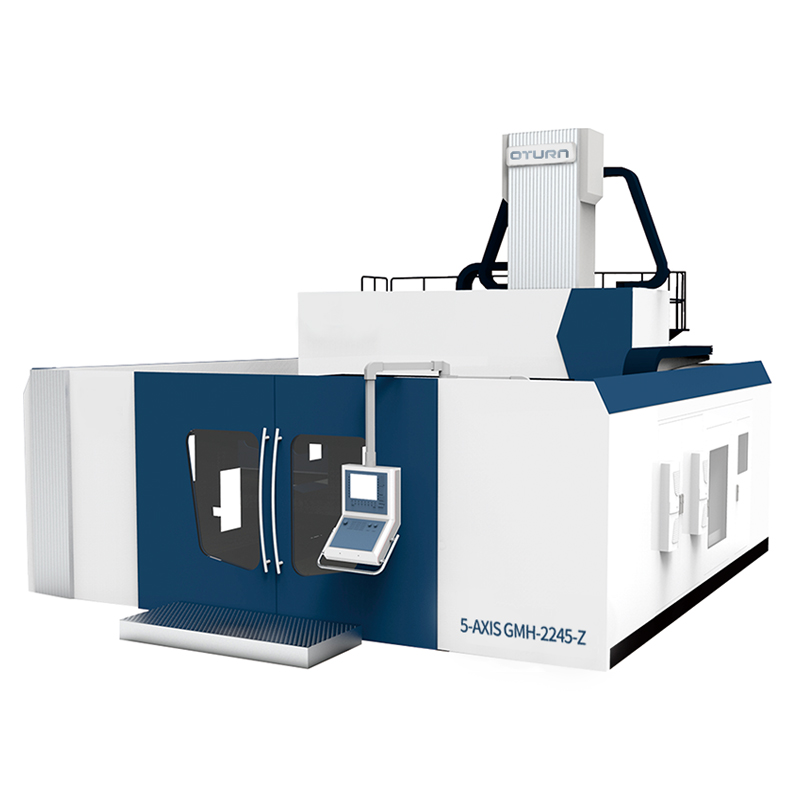

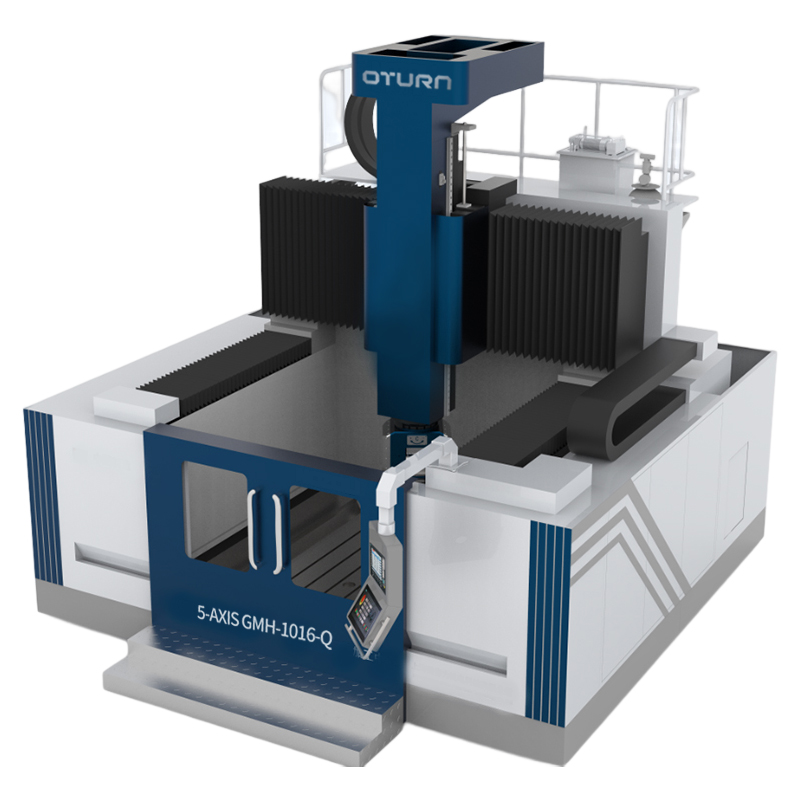

When it comes to precision and efficiency in machining, I trust gantry milling machines to deliver outstanding performance. Sourced from top manufacturers in China, these machines are built to tackle even the most demanding projects with ease. The robust construction and advanced technology ensure unparalleled accuracy, making them ideal for a variety of applications in manufacturing. I've seen firsthand how these gantry milling machines streamline production processes while minimizing operational costs. With options tailored to different production needs, I can customize the features to fit specific requirements. Whether you’re in aerospace, automotive, or any other industry that requires precision machining, investing in a high-quality gantry milling machine from a reputable manufacturer is crucial. Let’s elevate your manufacturing capabilities together and gain a competitive edge with reliable machinery that promises durability and performance. Reach out today to explore the options available.

gantry milling machine Supplier For the Current Year

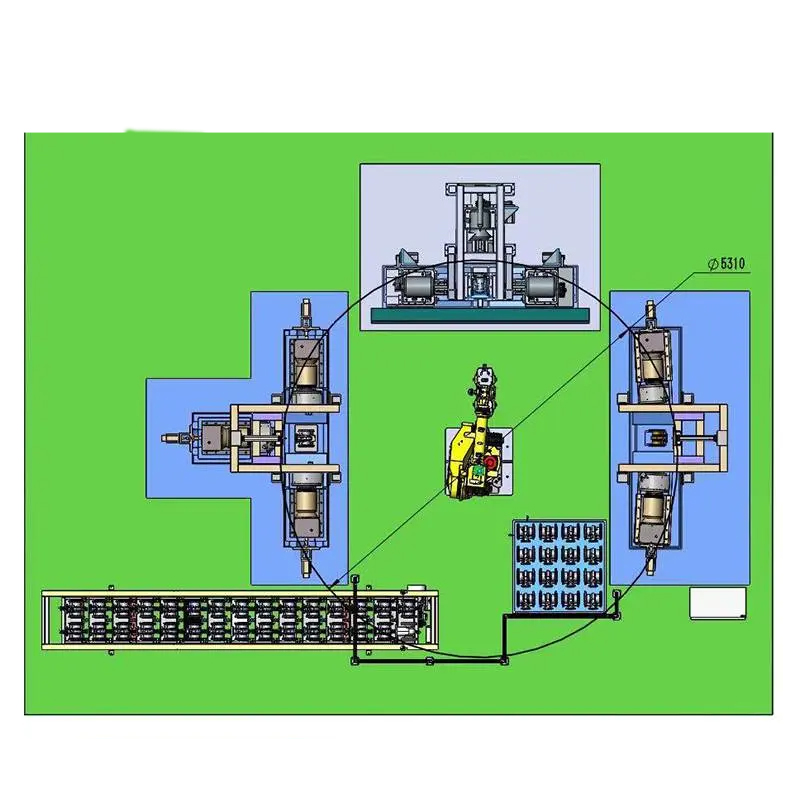

In the ever-evolving landscape of manufacturing, sourcing advanced machinery has become crucial for businesses looking to enhance their production capabilities. Among the key players in this domain, gantry milling machines stand out due to their precision, versatility, and efficiency in handling large workpieces. For global buyers, identifying a reputable supplier for gantry milling machines is essential to ensure seamless integration into production processes and to achieve superior output. A reliable supplier not only provides high-quality equipment but also offers comprehensive support, including customization options, technical assistance, and after-sales service. As companies expand their operations internationally, selecting a supplier that understands local market demands and can provide timely deliveries and robust service becomes increasingly important. Modern gantry milling machines are designed to meet stringent industry standards while incorporating cutting-edge technology that boosts productivity and reduces downtime. Investing in a gantry milling machine from a trusted supplier can significantly enhance manufacturing capabilities. With features such as multi-axis machining and automated operation, these machines enable manufacturers to maintain a competitive edge in a global market. As buyers assess their options for the current year, prioritizing innovation, reliability, and customer service will lead to forging successful partnerships that propel their businesses forward.

Gantry Milling Machine Supplier For the Current Year

| Model | Manufacturer | Specifications | Applications | Year of Manufacture |

|---|---|---|---|---|

| GM-1000 | Manufacturer A | X: 2000mm, Y: 1000mm, Z: 800mm | Aerospace, Automotive | 2023 |

| GM-2000 | Manufacturer B | X: 2500mm, Y: 1500mm, Z: 1000mm | Heavy Machinery, Electronics | 2023 |

| GM-3000 | Manufacturer C | X: 3000mm, Y: 2000mm, Z: 1500mm | Shipbuilding, Construction | 2023 |

| GM-4000 | Manufacturer D | X: 3500mm, Y: 2500mm, Z: 1200mm | Railway, Manufacturing | 2023 |

Related Products