Factory wholesale Cnc Vertical Turret Lathe - Two Face Turning Lathe – Oturn

Factory wholesale Cnc Vertical Turret Lathe - Two Face Turning Lathe – Oturn Detail:

Main features

(1)Our machines all feed with GSK Controller, can achieve double spindle linkage then finish to process Bore-hole, Screw thread and Sphere. The CNC Controller has good compatibility, powerful function and easy operation.

(2)The Feed Sliding table guideway use high quality gray casting iron,trough rough casting, tempering and aging treatment by three times. Fully eliminate the residual internal stress, The surface of the guide way adopts super audio quenching and the hardness is up to HRC55. Through high precision grinder processing, to ensure the accuracy, rigidity, stability.

(3)The transmission part adopts precision ball screw and interpolation to eliminate the gap,to ensure the machine drive steady.

(4)The power head is equipped with three – stage manual speed change with powerful motor,achieve low speed but high torque, can withstand heavy cutting load, improve processing efficiency.

(5)The working equipment adopts Hydraulic pressure-automatic clamping, to improve efficiency and reduce labor intensity.

(6)The machine adopts Centralized lubrication, to ensure that the full lubrication of each moving parts then improve the service life of machine tools.

CNC machine special for Valve is mainly used in processing Pipe,Valve, Pump body, Auto parts, Construction machinery parts etc.It can work for many procedures,for example, End face milling and boring, The outer circle, The front edge,Inner hole, Grooving, Screw thread, Bore-hole and Sphere.It worked with GSK CNC Controller, It can realize automation, high precision, multi variety and mass production.

Specification

|

Machining range |

Power head dia.(mm) |

φ400 |

|

|

Max.Machining Length(mm) |

Φ600 |

||

|

Max.Machining Dia.(mm) |

Φ460 |

||

|

Spindle |

Spindle Center Hight(mm) |

Φ385 |

|

|

Motor power(kw) |

5.5kw |

||

|

Spindle speed-Gear stepless (r/min) |

110/140/190 |

||

|

Feed |

Rapid Moving (mm/min) |

X-axis |

3000 |

|

Y-axis |

3000 |

||

|

Travel |

X-axis/Y-axis(mm) |

150/350 |

|

|

CNC Controller |

GSK |

980-TB3 |

|

|

Others |

Power |

AC 380V/50Hz |

|

|

lubrication |

Electronic lubrication |

||

|

Fixture |

Hydraulic clamping |

||

|

Weight(kg) |

3400 |

||

|

Dimension(mm) |

3400x2000x1800 |

||

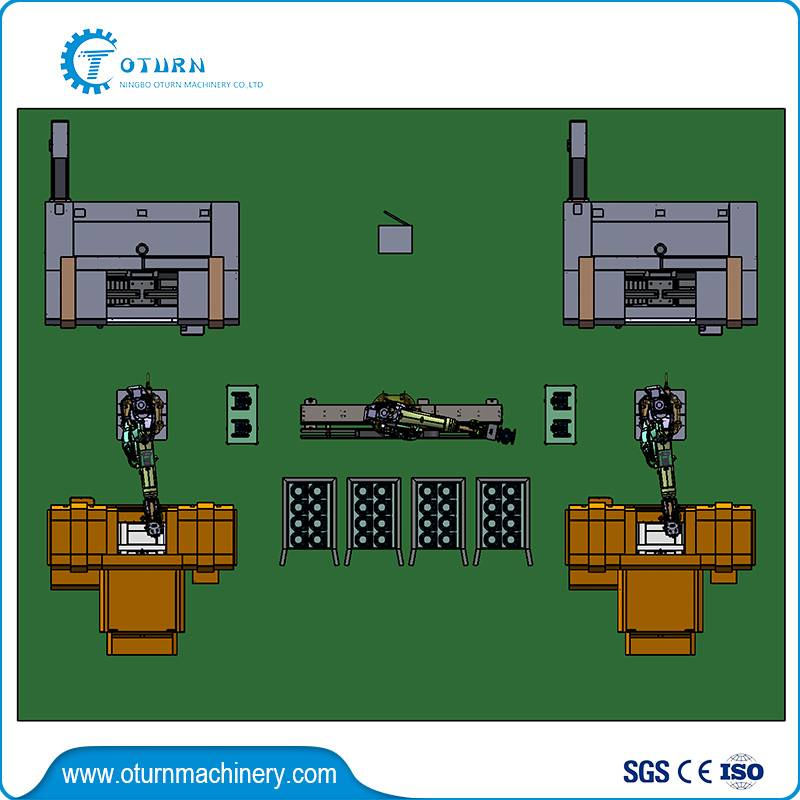

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Factory wholesale Cnc Vertical Turret Lathe - Two Face Turning Lathe – Oturn , The product will supply to all over the world, such as: Ukraine, Portugal, Hyderabad, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.