Factory directly Valve Turning Lathe - Robot Welding System For Valve – Oturn

Factory directly Valve Turning Lathe - Robot Welding System For Valve – Oturn Detail:

Specification

|

Model |

TKB 2670/2690 |

|

|

Payload |

20kg |

|

|

Max Working Radius |

1721*1921mm |

|

|

DOF |

6 axis |

|

|

Body weight |

210kg |

|

|

Reducer Brand |

import |

|

|

Rated Power |

7.5kw |

|

|

Max Speed |

J1 |

140°/s |

|

J2 |

111°/s |

|

|

J3 |

148°/s |

|

|

J4 |

234°/s |

|

|

J5 |

225°/s |

|

|

J6 |

360°/s |

|

|

Max Operation Area |

J1 |

±160° |

|

J2 |

150°~90° |

|

|

J3 |

80°~100° |

|

|

J4 |

±150° |

|

|

J5 |

±110° |

|

|

J6 |

±300° |

|

|

Protective Specification |

54 |

|

|

Position Repeat Accuracy |

±0.1mm |

|

|

Working Temperature |

0~45℃ |

|

|

With CE Certification |

||

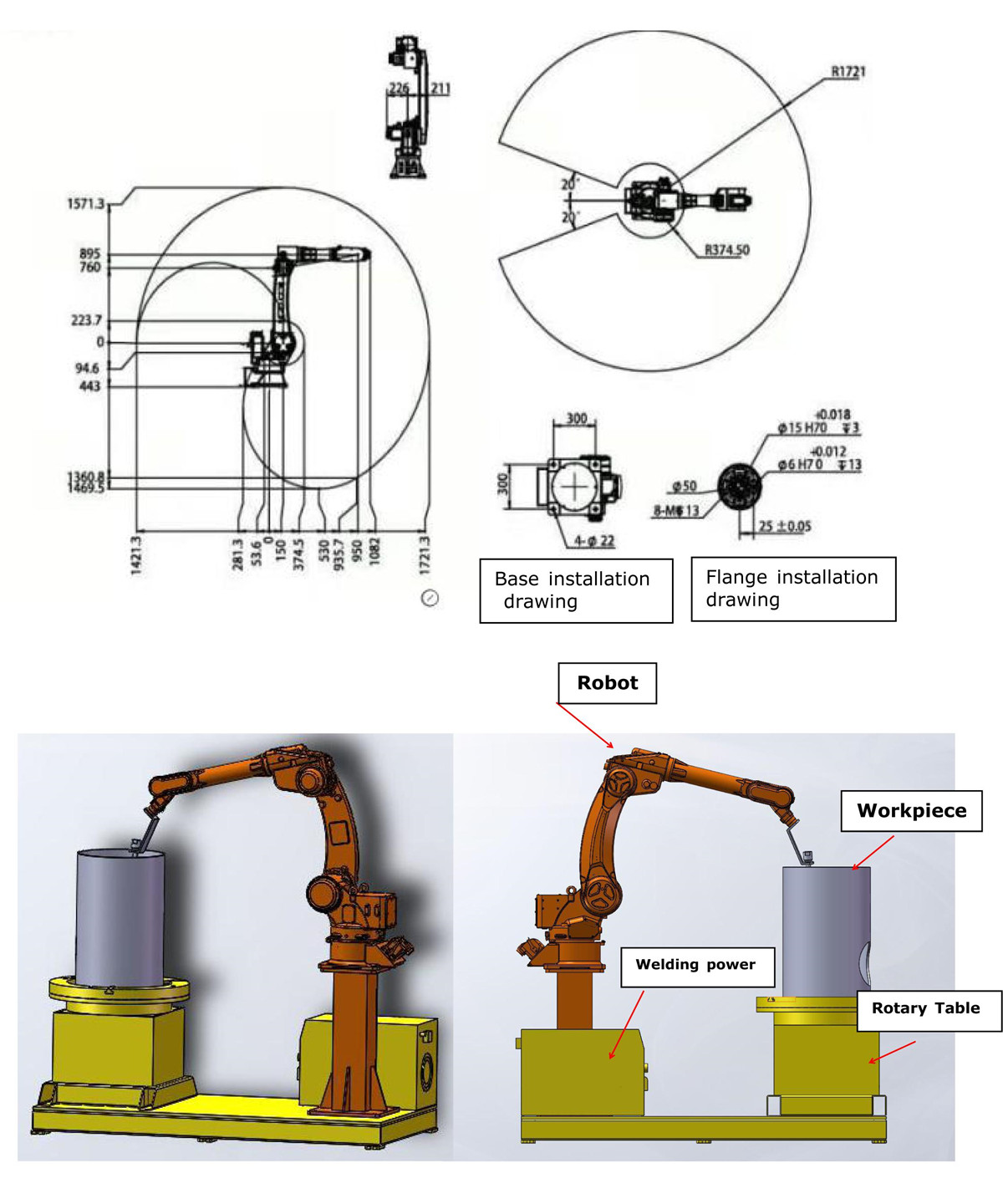

Working Layout

Welding machine

One machine is multi-purpose, and it can realize CO2/MAG welding, manual welding, carbon arc gouging at the same time, and exert its power in the processing of thick plates such as steel structures, bridges, and shipbuilding.

Microcomputer control, welding condition setting is a completely unified adjustment function, easy to operate.

In CO2/MAG welding, even if the hand shakes, the microcomputer can dynamically and quickly control it in real time to fully maintain the welding arc stability.

The carbon arc gouging function can realize back root removal and welding defects removal.

The SCR overcurrent protection function makes the performance of the welding machine more reliable.

The arc starting performance is superior, and it can be easily matched with the special plane.

Specification

|

Item |

XD600G |

||

|

Welding power |

model |

GPXDG-600 |

|

|

Input voltage |

V,Hz |

3,380V±10%,50/60Hz |

|

|

Rated input capacity |

kVA |

47.7(36.6kW) |

|

|

Output current range |

CO2/MAG/NMA |

A |

60~600 |

|

Carbon arc gouging |

100~600 |

||

|

Rated load duration |

% |

100 |

|

|

Dimensions(WHD) |

mm |

508*724*894 |

|

|

weight |

Kg |

252 |

|

|

Wire feeder |

model |

CMXL-2301 |

|

|

Welding gun |

model |

WT5000-SCD |

|

|

Gas flow regulator |

model |

W-198-36V |

|

|

Welding cable |

Model |

BKPT-7002 |

|

Product detail pictures:

Related Product Guide:

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for Factory directly Valve Turning Lathe - Robot Welding System For Valve – Oturn , The product will supply to all over the world, such as: Angola, Kazakhstan, Rotterdam, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.