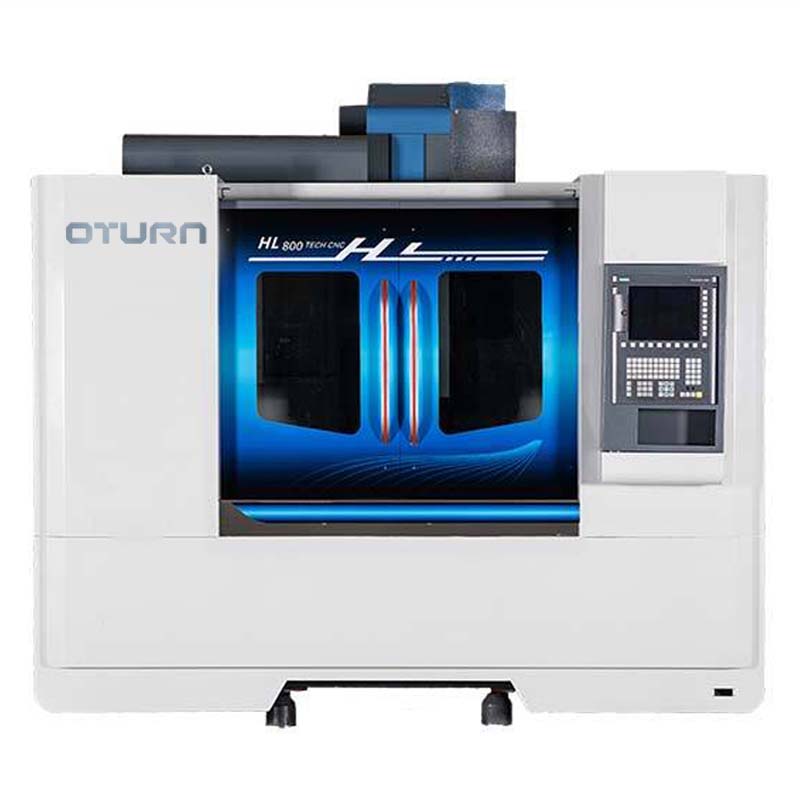

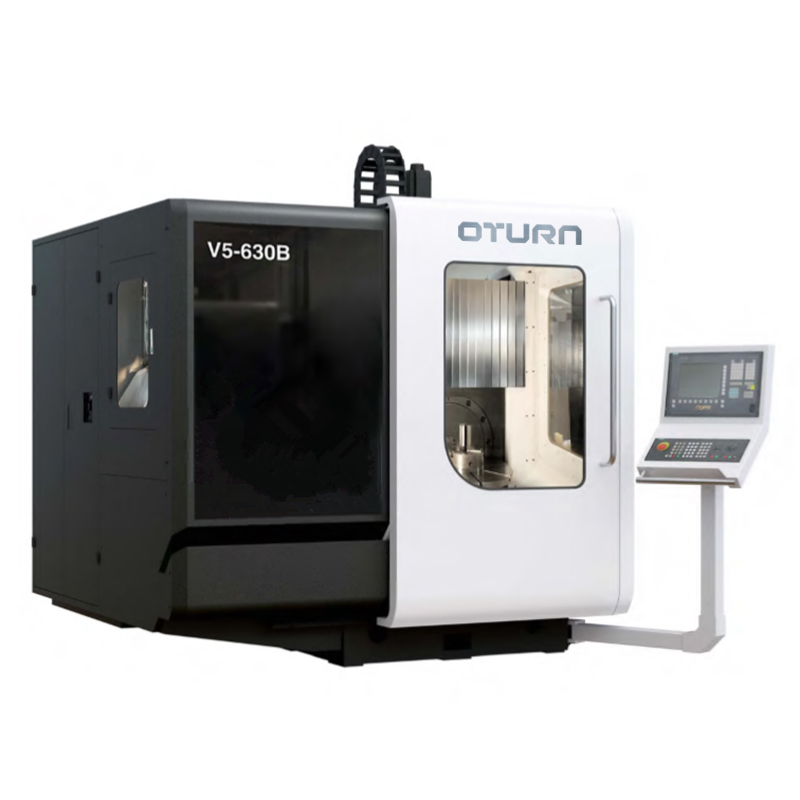

Top China Manufacturer of CNC Vertical Machining Centers for Precision Machining

As a B2B purchaser seeking high-quality machinery, I understand the importance of precision and efficiency in manufacturing. The CNC Vertical Machining Center I offer is not just a machine; it’s a game changer for your production line. Originating from top manufacturers in China, this equipment combines advanced technology with user-friendly features, making it ideal for various applications. With robust construction and versatility, this CNC Vertical Machining Center can handle complex jobs with ease, ensuring that your projects meet the highest standards. I’ve seen firsthand how this machine can enhance productivity and reduce downtime, ultimately leading to increased profitability. If you're ready to elevate your manufacturing process, let’s talk about how I can help. This is more than an investment in equipment; it’s an investment in your business's future.

Cnc Vertical Machining Center Industry Giant Trusted by Pros

As the demand for precision and efficiency in manufacturing continues to grow, CNC vertical machining centers have become essential tools for industry professionals worldwide. Renowned for their reliability and performance, these machines enable businesses to meet tight production deadlines while maintaining the highest quality standards. Purchasing such advanced equipment is an investment in productivity, allowing manufacturers to streamline operations and enhance their competitive edge. In today’s global marketplace, selecting the right machining center is critical. Key factors such as precision engineering, ease of use, and robust construction play a vital role in optimizing production processes. Professionals seek machines that not only offer superior capabilities but also deliver exceptional longevity, ensuring a sustainable return on investment. Furthermore, with the integration of advanced technologies, modern CNC vertical machining centers provide enhanced automation features that minimize human error and boost operational efficiency. For businesses looking to elevate their manufacturing capabilities, partnering with established leaders in the industry can make all the difference. By choosing a trusted provider, buyers can access ongoing technical support, comprehensive training, and a wide range of customizable solutions tailored to meet specific production needs. These partnerships foster innovation and empower companies to maximize their manufacturing potential in a rapidly evolving landscape.

Cnc Vertical Machining Center Industry Giant Trusted by Pros

| Feature | Description | Applications | Material Compatibility |

|---|---|---|---|

| High Precision | Achieves tolerances of ±0.001 mm. | Aerospace, Automotive | Aluminum, Titanium |

| Fast Machining | Utilizes high-speed spindles for reduced cycle times. | Medical Devices, Electronics | Plastics, Copper |

| User-Friendly Interface | Touchscreen controls simplify operations. | Small Batch Production, Prototyping | Steel, Nylon |

| Durability | Built with robust materials for long-term use. | Heavy Industries, Tooling | Cast Iron, Composite Materials |

| Automatic Tool Change | Minimizes downtime with efficient tool swapping. | Production Lines, Custom Fabrication | Various Metals, Wood |

Related Products