CNC Vertical Lathe RFCL63V/D For Wheel Hub

Product Configuration

Features

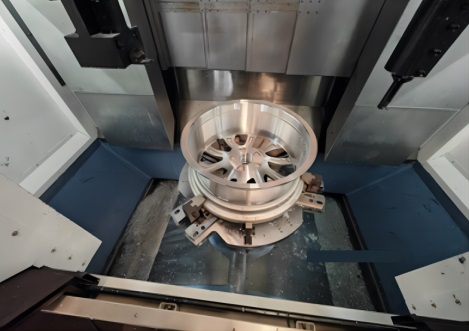

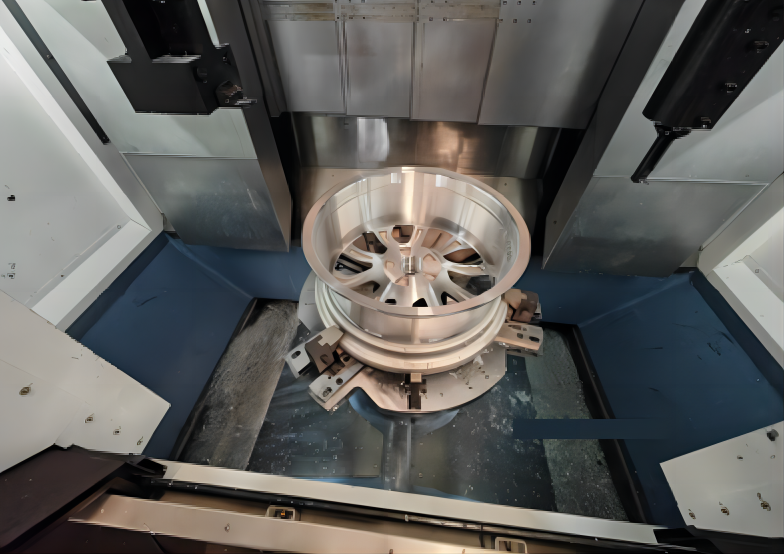

Safety and reliability are eternal themes. The 63L-V/D series is equipped with an air tightness detection to prevent accidents caused by wheel hub misalignment, misposition etc. If the above situation occurs, the machine will be shut down and an alarm will appear on the system panel, need operator intervention.

63L-V/D doors and windows are covered with 5mm thick steel plate, and the door glass is covered with 3mm thick pressure plates, which can withstand direct impact during high-speed processing of the wheel hub, and are safe and reliable.

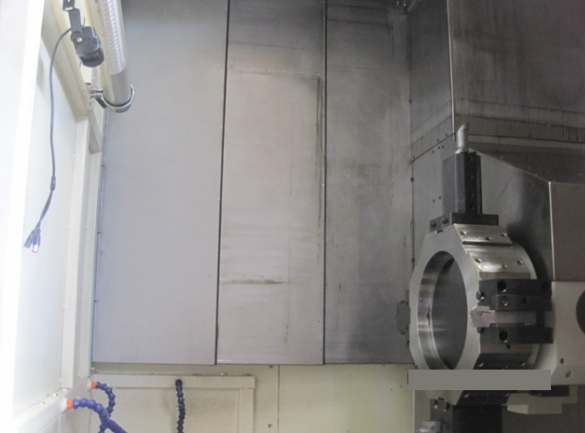

63L-V/D spindle left side is covered with a 5mm thick steel plate, which can withstand direct impact during high-speed machining of the wheel hub, and is safe and reliable.

Continuous processing for 8 hours

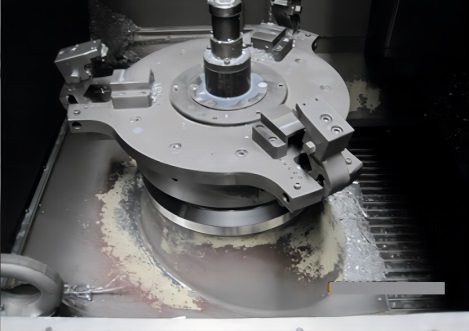

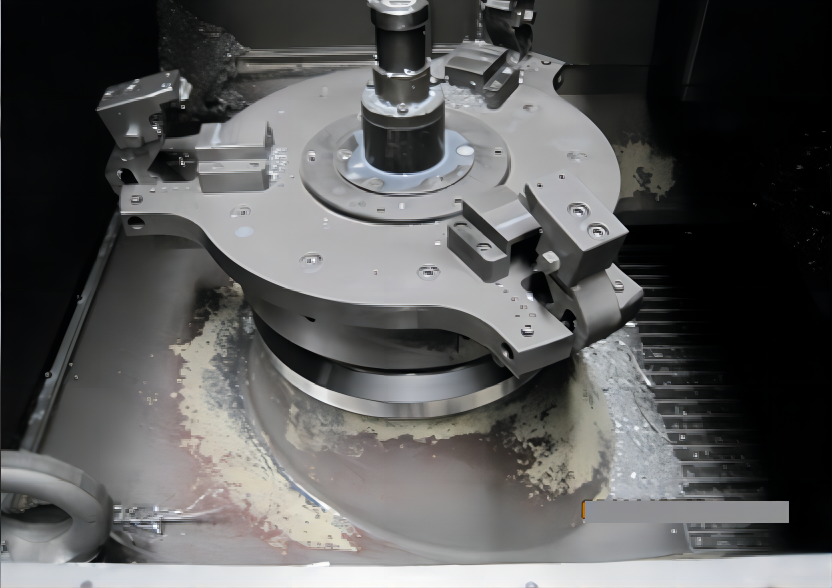

Chip removal position adopts a large angle design. Stainless steel sheet metal is added to the places where chips are easy to accumulate, which can effectively reduce chip accumulation. At the same time, 2 chip conveyors (RFCL63D) are equipped to reduce the frequency of operator intervention, thereby reducing standby time. The picture shows the chip situation after 8 hours of processing.

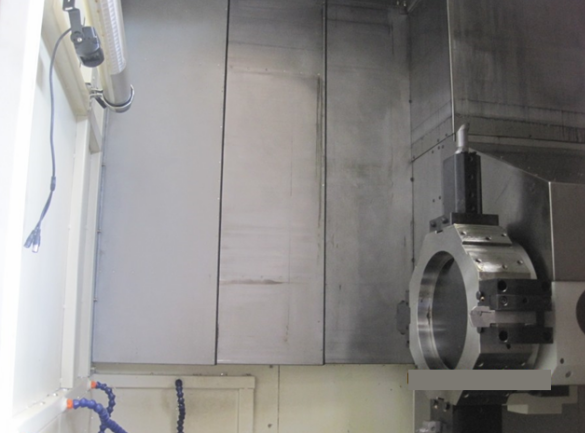

63LV/D internal protection adopts a fully enclosed structure, which can effectively prevent coolant and aluminum chips from entering the guide rail area.

The top of the 63LV/D turret is tilted at 45° to prevent aluminum chips accumulation.

Technical Specifications

|

Item |

Unit |

RFCL63V(single tool tower) |

RFCL63D(Dual tool tower) |

|

|

Working range |

Max swing diameter on bed |

mm |

φ900 |

φ900 |

|

Max swing diameter on carriage |

mm |

φ800 |

φ800 |

|

|

Max cutting diameter |

mm |

φ700 |

φ700 |

|

|

Max cutting height |

mm |

600 |

380 |

|

|

Max travel on Z axis |

mm |

650 |

650 |

|

|

Max travel on X axis |

mm |

450+10 |

450+10 |

|

|

Spindle |

Max spindle speed |

rpm |

2500 |

2000 |

|

Max spindle power |

kw |

30/37 |

45/55 |

|

|

Spindle head |

|

A2-8 |

A2-11 |

|

|

Spindle through hole |

mm |

φ90 |

φ90 |

|

|

Feeding system |

Rapid move speed X/Z |

m/min |

20/24 |

20/24 |

|

Servo motor X/Z |

N.m |

22/22 |

22/22 |

|

|

Tool holder |

Tool number |

Set |

8 |

8+8 |

|

Standard OD tool size |

mm |

32*32 |

32*32 |

|

|

ID tool size |

mm |

φ50 |

φ50 |

|

|

Repeatability positioning accuracy |

mm |

0.003 |

0.003 |

|

|

Tool exchange time |

S |

0.25 |

0.25 |

|

|

Clamp device |

Chuck, oil cylinder |

|

Special fixture for wheel hub |

special fixture for wheel hub |

|

Cooling system |

Cooling tank volume |

L |

250 |

350 |

|

Hydraulic lubrication system |

Hydraulic system P/Q |

MPa; L/min |

3.5; 30 |

3.5; 30 |

|

Lubrication system |

/ |

Fixed time/volume lubrication |

||

|

Positioning accuracy |

Positioning accuracy X/Z |

mm |

0.008/0.012 |

0.008/0.012 |

|

Repeatability positioning accuracy X/Z |

mm |

0.004/0.006 |

0.004/0.006 |

|

|

Others |

Machine size(length*width*height) |

mm |

2375x2730x3050 |

3600×2730x3150 |

|

Machine weight |

kg |

10000 |

15000 |

|

Standard configuration

1. Control system: FANUC/SIEMENS

2. Mechanical spindle

3. Fully closed. Protection

4. Chain plate chip conveyor+cart

5. Servo tool tower

6. Fixture on wheel hub

7. Hand hold hand wheel

8. Electric cabinet heat exchanger

9. Three-color light, work light

10. Hydraulic lubrication

Optional configuration

1. Electric spindle

2. Power tool post

3. Automatic door

4. Tool detection

5. High pressure chip removal

6. Measuring system online

7. Paper fileter system

8. Adapt connection function

Safety and reliability are eternal themes. The 63L-V/D series is equipped with an air tightness detection to prevent accidents caused by wheel hub misalignment, misposition etc. If the above situation occurs, the machine will be shut down and an alarm will appear on the system panel, need operator intervention.

63L-V/D doors and windows are covered with 5mm thick steel plate, and the door glass is covered with 3mm thick pressure plates, which can withstand direct impact during high-speed processing of the wheel hub, and are safe and reliable.

63L-V/D spindle left side is covered with a 5mm thick steel plate, which can withstand direct impact during high-speed machining of the wheel hub, and is safe and reliable.

Continuous processing for 8 hours

Chip removal position adopts a large angle design. Stainless steel sheet metal is added to the places where chips are easy to accumulate, which can effectively reduce chip accumulation. At the same time, 2 chip conveyors (RFCL63D) are equipped to reduce the frequency of operator intervention, thereby reducing standby time. The picture shows the chip situation after 8 hours of processing.

63LV/D internal protection adopts a fully enclosed structure, which can effectively prevent coolant and aluminum chips from entering the guide rail area.

The top of the 63LV/D turret is tilted at 45° to prevent aluminum chips accumulation.

|

Item |

Unit |

RFCL63V(single tool tower) |

RFCL63D(Dual tool tower) |

|

|

Working range |

Max swing diameter on bed |

mm |

φ900 |

φ900 |

|

Max swing diameter on carriage |

mm |

φ800 |

φ800 |

|

|

Max cutting diameter |

mm |

φ700 |

φ700 |

|

|

Max cutting height |

mm |

600 |

380 |

|

|

Max travel on Z axis |

mm |

650 |

650 |

|

|

Max travel on X axis |

mm |

450+10 |

450+10 |

|

|

Spindle |

Max spindle speed |

rpm |

2500 |

2000 |

|

Max spindle power |

kw |

30/37 |

45/55 |

|

|

Spindle head |

A2-8 |

A2-11 |

||

|

Spindle through hole |

mm |

φ90 |

φ90 |

|

|

Feeding system |

Rapid move speed X/Z |

m/min |

20/24 |

20/24 |

|

Servo motor X/Z |

N.m |

22/22 |

22/22 |

|

|

Tool holder |

Tool number |

Set |

8 |

8+8 |

|

Standard OD tool size |

mm |

32*32 |

32*32 |

|

|

ID tool size |

mm |

φ50 |

φ50 |

|

|

Repeatability positioning accuracy |

mm |

0.003 |

0.003 |

|

|

Tool exchange time |

S |

0.25 |

0.25 |

|

|

Clamp device |

Chuck, oil cylinder |

Special fixture for wheel hub |

special fixture for wheel hub |

|

|

Cooling system |

Cooling tank volume |

L |

250 |

350 |

|

Hydraulic lubrication system |

Hydraulic system P/Q |

MPa; L/min |

3.5; 30 |

3.5; 30 |

|

Lubrication system |

/ |

Fixed time/volume lubrication |

||

|

Positioning accuracy |

Positioning accuracy X/Z |

mm |

0.008/0.012 |

0.008/0.012 |

|

Repeatability positioning accuracy X/Z |

mm |

0.004/0.006 |

0.004/0.006 |

|

|

Others |

Machine size(length*width*height) |

mm |

2375x2730x3050 |

3600×2730×3150 |

|

Machine weight |

kg |

10000 |

15000 |

|