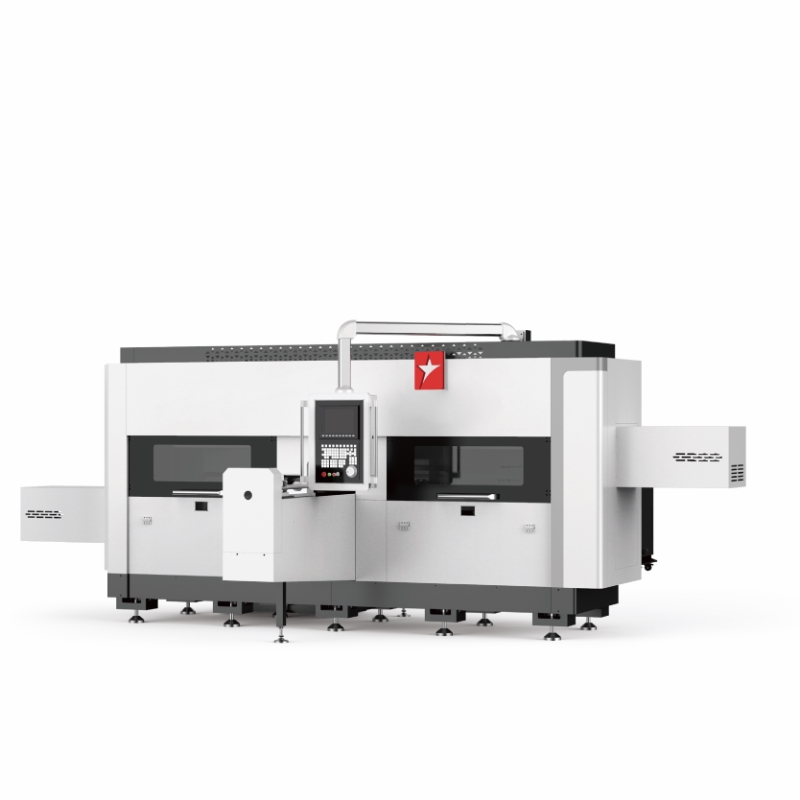

Cnc Turning Centre Machine Manufacturer in China for Precision Engineering

When I first came across the CNC Turning Centre Machine, I knew it was a game changer for our production line. Designed to enhance precision and efficiency, this machine from a reputed China manufacturer stands out in the crowded market. It's perfect for creating complex parts with ease, making it an ideal choice for businesses like mine that demand high-quality machining. With intuitive controls and advanced technology, I found it easy to operate, which saved us time and training costs. The durability and reliability of the CNC Turning Centre Machine impressed me, ensuring it withstands the rigors of constant use. Plus, the manufacturer offered outstanding support and service, which is crucial for maintaining productivity. If you're in the market for a CNC Turning Centre Machine, investing in one from a leading China manufacturer could be the best decision. It not only boosts production but also elevates the quality of your output, helping you stay ahead in a competitive landscape.

Cnc Turning Centre Machine in 2025 Sets the Industry Standard

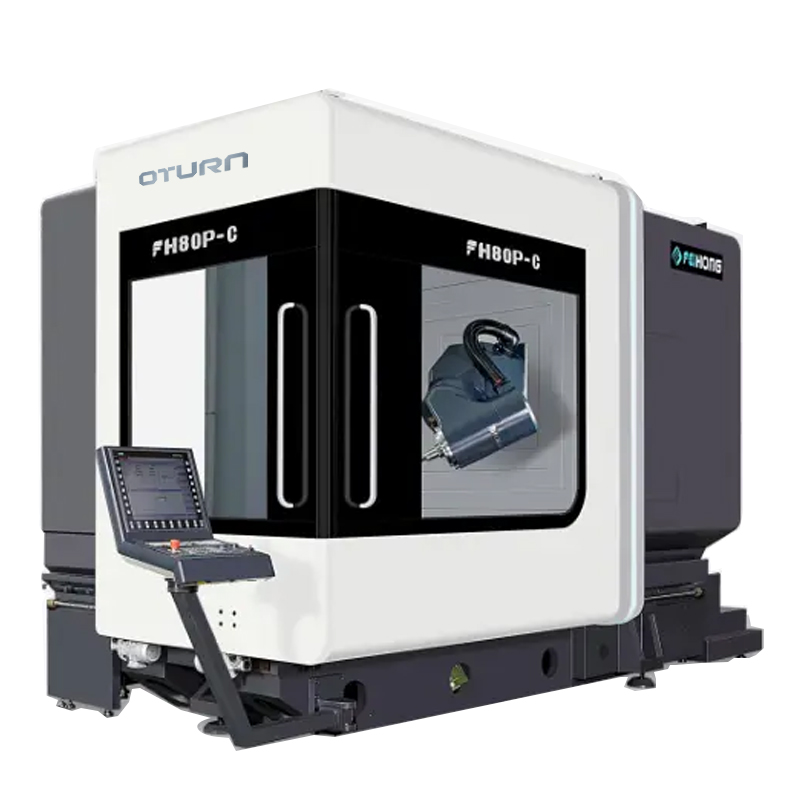

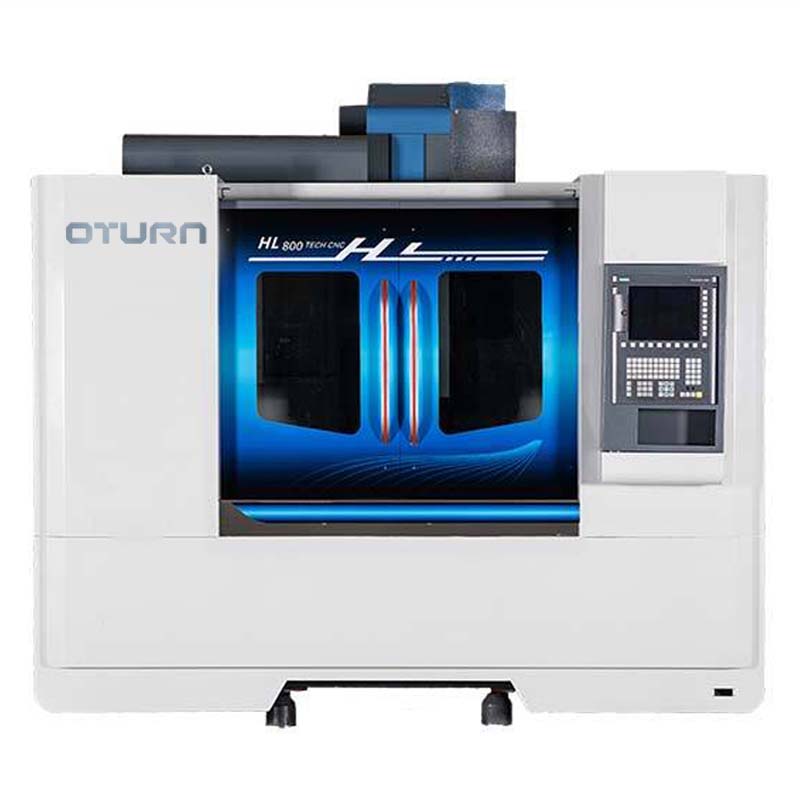

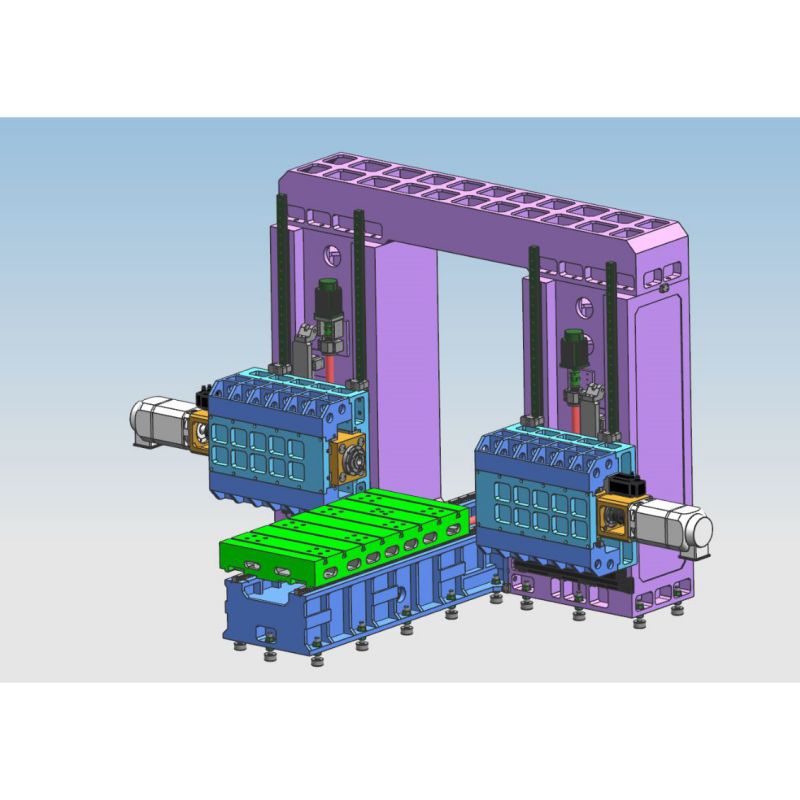

As we advance towards 2025, the landscape of manufacturing continues to evolve, with CNC turning centre machines setting the new industry standard. These advanced machines not only enhance precision and efficiency but also offer unprecedented versatility for various applications. With increasing global competition, manufacturers seek reliable machinery that ensures superior quality while reducing production costs. The latest CNC turning technologies incorporate intelligent automation and real-time monitoring, enabling operators to optimize workflows and maximize output. This shift towards smart manufacturing is essential for businesses aiming to stay competitive in a rapidly changing market. Furthermore, as sustainability becomes a critical focus, these machines are designed to minimize material waste and energy consumption, aligning with global efforts to promote environmentally friendly production practices. Investing in state-of-the-art CNC turning centre machines is becoming essential for companies aiming to meet the growing demands of their clients worldwide. As we look towards the future, adopting these advanced technologies will not only bolster productivity but also enhance the overall quality of manufactured products, setting a benchmark for excellence in the industry.

Cnc Turning Centre Machine in 2025 Sets the Industry Standard

| Feature | Specifications | Benefits |

|---|---|---|

| Spindle Speed | 6000 RPM | Increased productivity and reduced machining time. |

| Cutting Tools | Insert Type Carbide Tools | Enhanced tool life and better surface finish. |

| Control System | CNC with Touchscreen Interface | User-friendly operation with advanced programming capabilities. |

| Axis Movement | 3-Axis CNC | Improved accuracy and versatility in machining. |

| Material Compatibility | Aluminum, Steel, Titanium | Broad application range across various industries. |

Related Products