CNC Special Purpose Machine Manufacturer in China | Precision Engineering

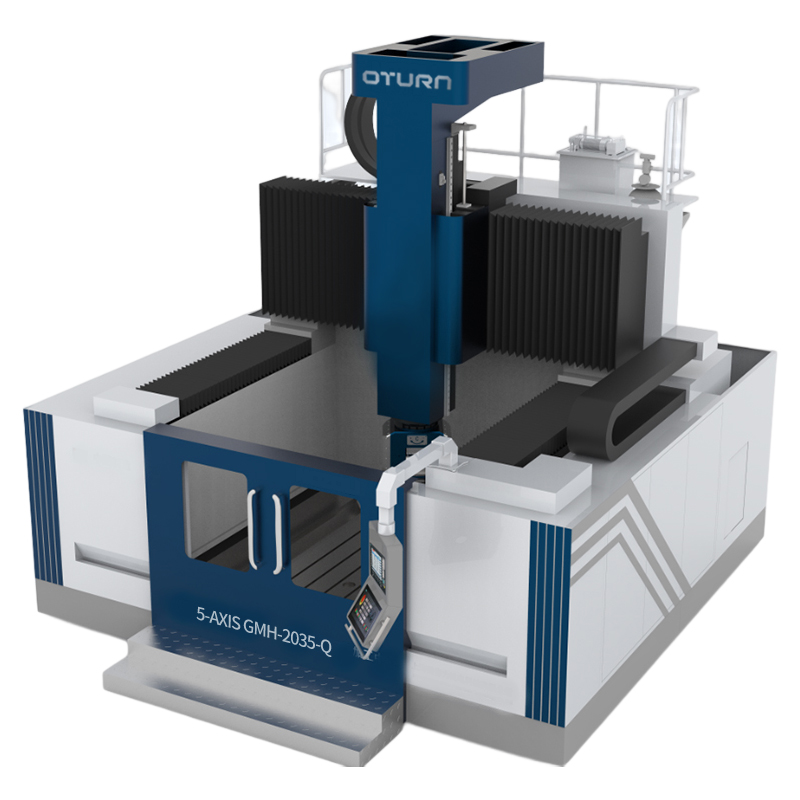

In my experience as a supplier of CNC special purpose machines in China, I understand the unique needs of various industries. Our machines are designed to enhance precision and efficiency, tailored to specific manufacturing processes. Whether you're in automotive, aerospace, or any custom application, you'll find our equipment exceptionally reliable. As a manufacturer, we prioritize durability and innovation, ensuring that our CNC machines meet the highest standards. We take pride in offering not just equipment, but comprehensive support throughout your purchase journey. From selection to installation, I'm here to assist you every step of the way. Choosing our CNC special purpose machine means investing in quality and performance that drives your production forward. Let’s work together to elevate your operations!

Cnc Special Purpose Machine Custom Solutions, Outperforms the Competition

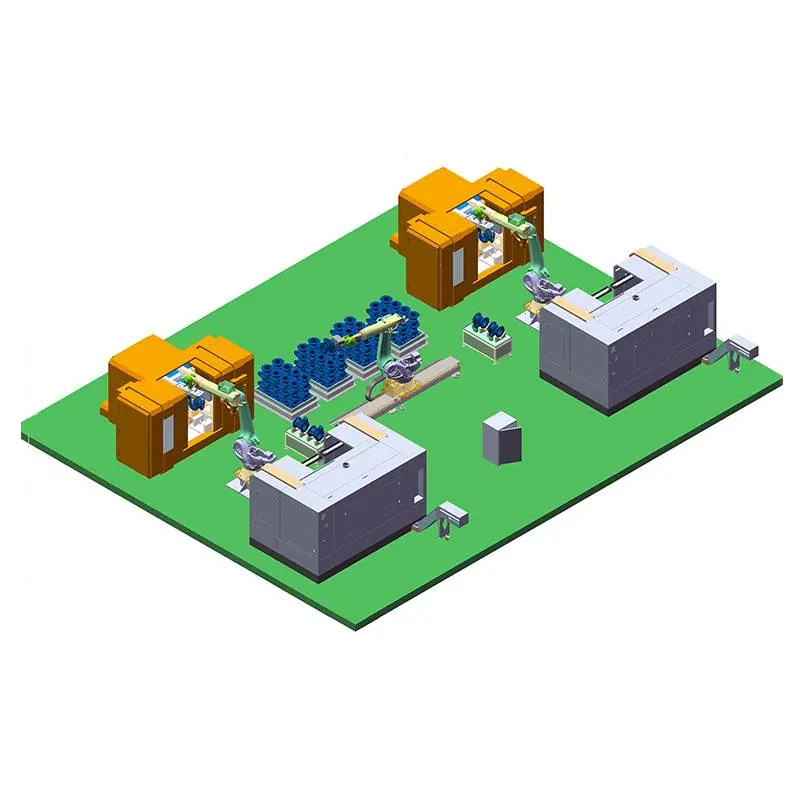

In today's competitive manufacturing landscape, the demand for specialized solutions is rapidly growing. Businesses are continuously seeking innovative ways to enhance efficiency and reduce production costs. Custom CNC special purpose machines stand out as a pivotal investment for companies aiming to streamline their operations. By utilizing advanced technologies and tailored designs, these machines can significantly outperform generic alternatives, providing major advantages in both precision and output. The key to surpassing competitors lies in the ability to tailor equipment to specific production needs. Custom CNC solutions allow manufacturers to optimize their processes, reduce waste, and achieve higher quality results. Whether it’s for intricate part fabrication or high-volume production, these machines offer unmatched flexibility and performance. Investing in custom machinery not only enhances production capabilities but also positions companies to respond swiftly to market demands, ensuring they remain relevant and competitive in their respective industries. As global procurement trends shift towards more personalized and efficient tools, embracing the potential of custom CNC special purpose machines can unlock new opportunities. By understanding the unique requirements of their operations and integrating advanced technology, manufacturers can achieve remarkable efficiency, improve product quality, and ultimately drive profitability. As the industry evolves, those who adapt and innovate with specialized solutions will likely lead the charge in market excellence.

Cnc Special Purpose Machine Custom Solutions, Outperforms the Competition

| Solution Type | Material Compatibility | Precision (mm) | Cycle Time (sec) | Customization Level |

|---|---|---|---|---|

| CNC Milling | Aluminum, Steel | 0.01 | 60 | High |

| CNC Turning | Brass, Stainless Steel | 0.02 | 50 | Medium |

| CNC Plasma Cutting | Mild Steel, Aluminum | 0.5 | 30 | Low |

| CNC Wire EDM | Tool Steel, Titanium | 0.001 | 120 | High |

| CNC Laser Cutting | Acrylic, Wood | 0.3 | 40 | Medium |

Related Products