CNC Pipe Thread Lathe Machine Manufacturer in China - Quality & Precision

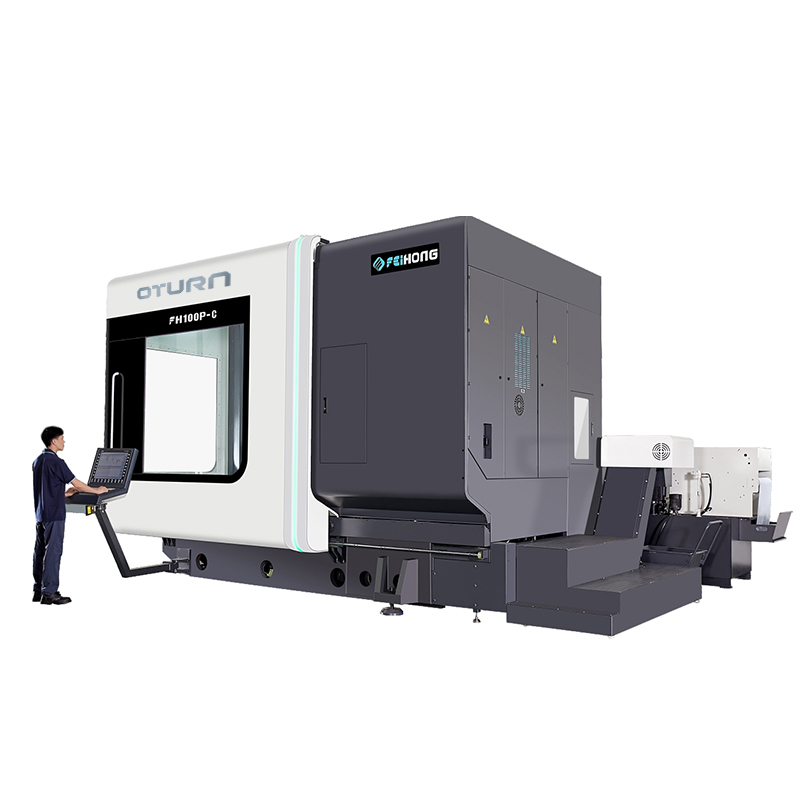

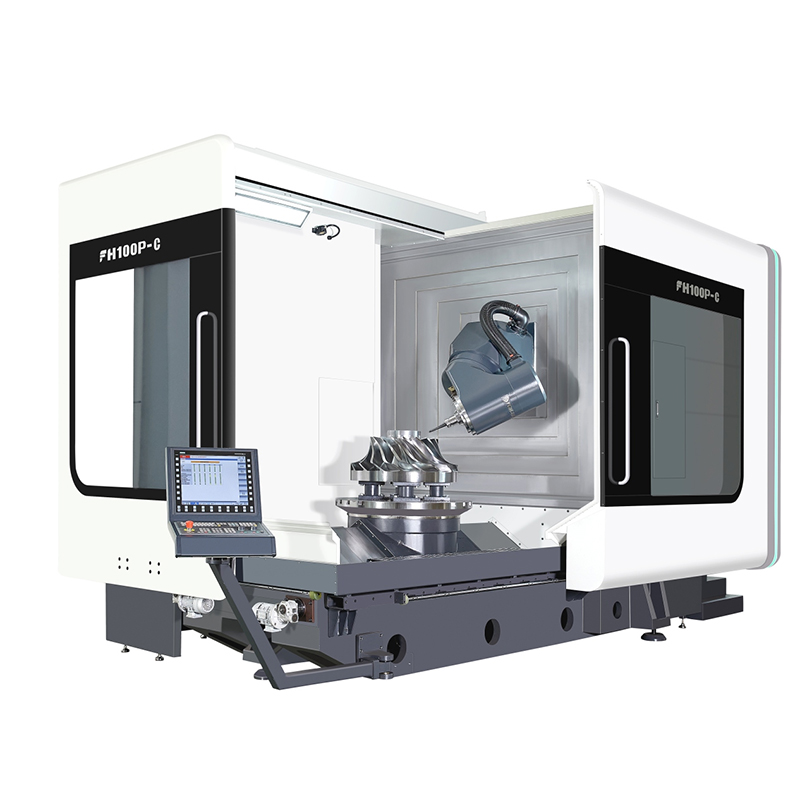

As a B2B purchaser, you know the importance of reliable machinery for your operations. Our Cnc Pipe Thread Lathe Machine, meticulously crafted in China, stands out as a top choice for manufacturers seeking precision and efficiency. With advanced features tailored for threading various pipe sizes, it simplifies complex tasks, thus boosting your productivity. I appreciate how this machine is built with durability in mind, ensuring it can handle the rigors of continuous use while maintaining accuracy. Choosing a manufacturer with a strong reputation like ours guarantees not just quality but also ongoing support and service. We take pride in our commitment to innovation and customer satisfaction, which means you can trust us to meet your specific needs. By investing in our Cnc Pipe Thread Lathe Machine, you’re making a wise decision that will elevate your production capabilities and keep your operations running smoothly. Let’s enhance your manufacturing process together!

Cnc Pipe Thread Lathe Machine Service in 2025

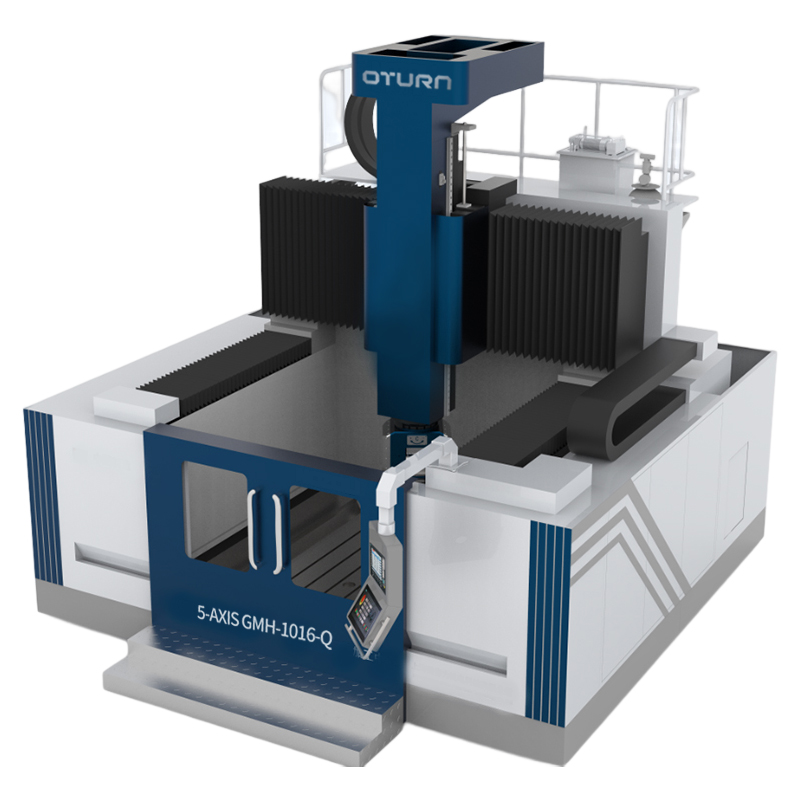

As the manufacturing sector continues to evolve, the demand for precision and efficiency has never been more critical. In 2025, CNC pipe thread lathe machines stand at the forefront of this transformation, offering unparalleled accuracy in threading operations while optimizing production timelines. For global buyers seeking to enhance their operations, investing in advanced CNC technology can lead to significant improvements in productivity and quality. The latest CNC pipe thread lathes are designed for versatility and high-performance capabilities. They can handle a wide range of pipe sizes and materials, making them an ideal choice for manufacturers in various industries, from energy to construction. Additionally, with integrated automation features, these machines streamline operations, reduce manual intervention, and enhance worker safety. Buyers looking to remain competitive in today's fast-paced market will find that the adoption of such technology is not just an option but a necessity for sustained growth. Furthermore, as sustainability becomes an increasing focus within manufacturing, modern CNC lathe machines are engineered with energy-efficient designs and reduced waste generation. This aligns with global trends towards greener production methods. By choosing to invest in CNC pipe thread lathe machines, companies can significantly lower their environmental impact while also meeting the rising demands for efficiency and quality in their output. Embracing these innovations will not only drive operational success but also position businesses as leaders in sustainable manufacturing practices.

Cnc Pipe Thread Lathe Machine Service in 2025

| Service Type | Description | Completion Time | Technician Expertise | Customer Feedback |

|---|---|---|---|---|

| Installation | Complete setup of CNC lathe for pipe threading | 2 Days | Senior Engineer | 4.8/5 |

| Maintenance | Regular check-up and adjustment services | 1 Day | Certified Technician | 4.7/5 |

| Repair | Troubleshooting and fixing mechanical issues | Variable (1-3 Days) | Experienced Specialist | 4.6/5 |

| Training | Operator training for CNC lathe usage | 3 Days | Technical Instructor | 4.9/5 |

Related Products