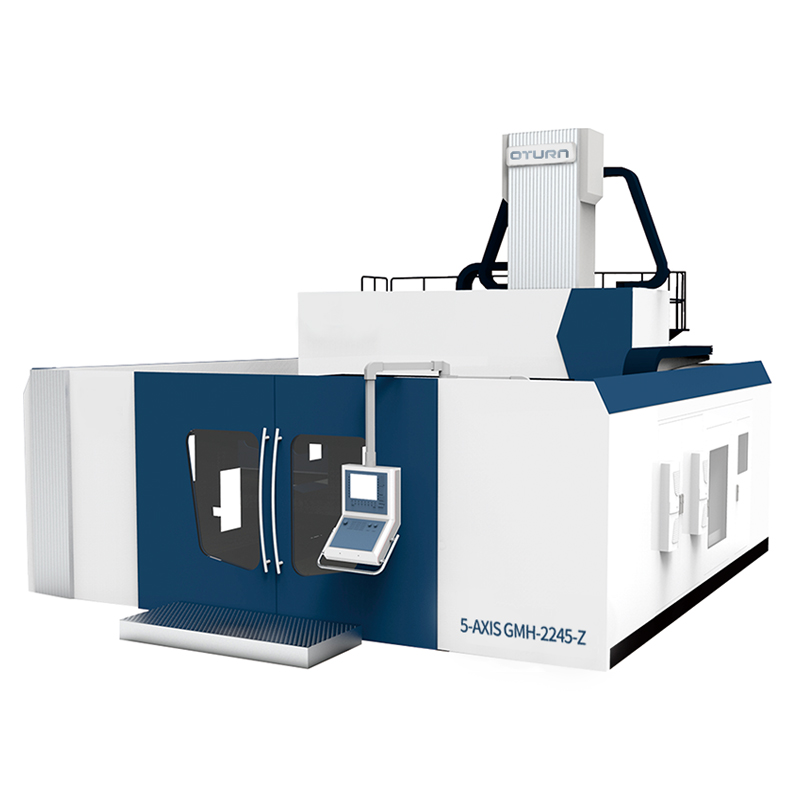

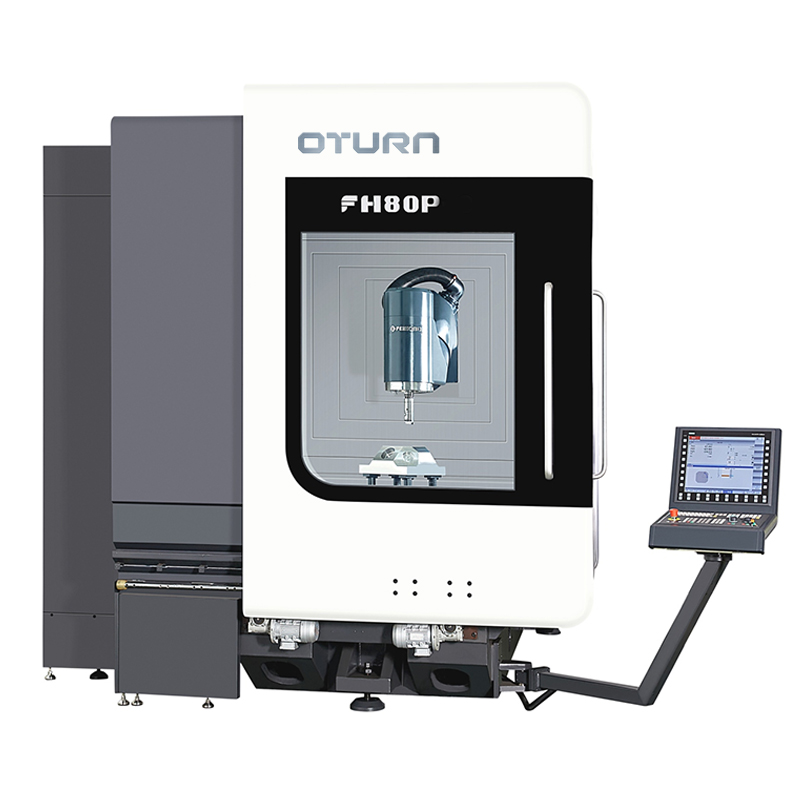

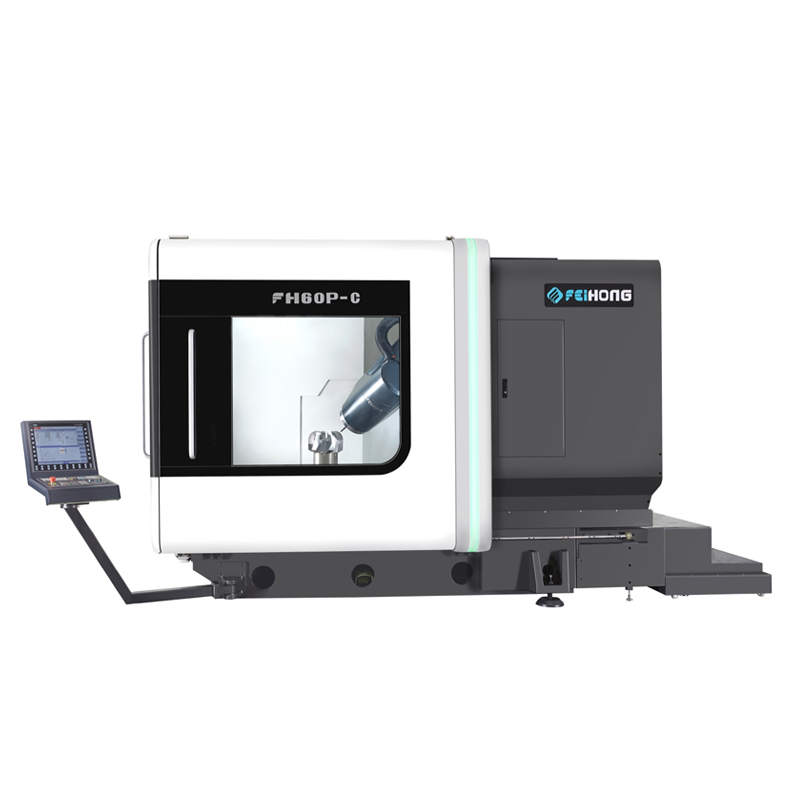

CNC Machinery from China: Trusted Manufacturer for Precision Solutions

As a CNC machinery supplier, I understand the unique needs of businesses looking for precision and quality. Sourcing from China gives you incredible options, with manufacturers renowned for their cutting-edge technology and competitive pricing. Our CNC machinery is designed to enhance your production efficiency, whether you're in metalworking, woodworking, or plastic fabrication. When you partner with us, you’re not just getting equipment; you’re accessing a wealth of expertise and support. I’ve seen what the right machinery can do for a company’s output and bottom line. The durability and accuracy of our CNC solutions ensure that your projects meet and exceed industry standards. Let's talk about how our equipment can streamline your operations and help your business thrive in today’s competitive landscape. Your success is our priority, and I’m here to assist every step of the way. Feel free to reach out for more information or to discuss specific machinery needs.

CNC Machinery Now Trending Winning in 2025

As we approach 2025, the industry landscape for CNC machinery is witnessing significant transformation. The latest technologies are driving efficiency, precision, and sustainability, making CNC machines indispensable for manufacturers worldwide. With automation on the rise, businesses that invest in state-of-the-art CNC technology can enhance productivity while reducing operational costs. This shift not only improves production capabilities but also enables companies to respond to market demands more swiftly, providing a competitive edge. Moreover, the sustainability aspect of CNC machinery cannot be overlooked. Eco-friendly manufacturing practices are becoming increasingly important for buyers concerned about their carbon footprint. CNC machines equipped with advanced features optimize material usage and minimize waste, aligning with global sustainability goals. This trend is not just about compliance; it reflects a broader commitment to responsible manufacturing that resonates with conscientious consumers and businesses alike. Global buyers are urged to stay ahead of the curve and consider how these advancements can streamline their operations. Investing in cutting-edge CNC machinery will not only meet current production needs but also future-proof businesses against the ever-evolving manufacturing landscape. As we move forward, embracing innovation will be key to thriving in a competitive market.

CNC Machinery Now Trending Winning in 2025

| Machine Type | Applications | Trends | Industry Growth (%) | Projected Revenue ($ Billion) |

|---|---|---|---|---|

| CNC Milling Machines | Metal Fabrication, Aerospace | Automation Integration | 12% | 15.5 |

| CNC Lathes | Automotive Parts, Electronics | Smart Features | 10% | 8.2 |

| CNC Plasma Cutters | Construction, Metal Works | Increased Precision | 15% | 5.0 |

| CNC Laser Cutters | Sign Making, Aerospace | Eco-friendly Technology | 9% | 6.8 |

| CNC Routers | Woodworking, Signage | Versatile UseCases | 11% | 7.3 |

Related Products