CNC Horizontal Heavy Roughing Machining Center HB Series

Features

Table Type Horizontal Machining Center

X / Z axis is a linear guideway,Y axis is a hard guideway.

The spindle box is full-gear structure, with large torque.

High cost performance, suitable for rough and semi finish machining.

Moving Column Heavy Roughing Horizontal Machining Center

Moving column structure.

X / Z axis is a linear guideway, Y axis upgraded to hard guideway, Y-axis column rigidity enhancement.

Gearbox upgrade, cutting efficiency greatly improved.

Upgrade to a new type of shield.

The spindle speed is upgraded to 4500 rpm.

Floor Type CNC Horizontal Machining Center (heavy roughing machine)

Heavy-duty cutting and heavy-load, a sharp tool for roughing and semi-finishing, durable.

Floor-standing structure, large load-bearing capacity.

Full gear 10-3000 revolutions, torque can reach more than 1000N.m.

Ram can extend 700mm for processing.

A sharp tool for roughing and semi-finishing automobile molds. .

The motor torque is increased by 30-37kw, the gear is enlarged, the strip structure is optimized, and the cutting force is greatly enhanced.

Technical Specifications

|

Item |

H B 1 7 1 2 ( Worktable type ) |

H B 1 8 1 2 (Moving column type ) |

HB2516/HB3016/HB3020(Floor-standing type) |

|

|

Processing range |

||||

|

X-axis travel |

mm |

1700 (the worktable moves left and right) |

1800 (the worktable moves left and right) |

2500/3000/3000 (column moves left and right) |

|

Y-axis travel |

mm |

1200 (the spindle box moves up and down) |

1200 (the spindle box moves up and down) |

1600/1600/2000 (spindle box moves up and down) |

|

Z-axis travel |

mm |

700 (the worktable moves forward and backward) |

800 (the column moves forward and backward) |

700 (ram extends forward and backward) |

|

Spindle center to table |

mm |

0-1200 |

130-1330 |

100-1700/100-1700/100-2100 |

|

Spindle end face to table center |

mm |

150-850 |

200-1000 |

200 |

|

Guide rail type |

|

XZ axis linear guide/Y axis hard guide |

XZ axis linear guide/Y axis hard guide |

|

|

Worktable |

||||

|

Worktable dimensions |

mm |

1700*850 |

1600*1000 |

2500*1550/3000*1550/3000*1550 |

|

Worktable load bearing |

kg |

5000 |

8000 |

30000 |

|

T-slot specifications (width*spacing) |

mm |

18*150 |

22*150 |

22*200 |

|

Spindle |

||||

|

Drive mode |

|

Full gear |

Full gear |

Full gear |

|

Maximum speed |

rpm |

3000 |

4500 |

3000 |

|

Spindle power |

kW |

15/18.5 |

15/18.5 |

30/37 |

|

Maximum spindle torque |

N.m |

286/472 |

473/894 |

498/748 |

|

Spindle taper/pull pin |

|

BT50-45° |

BT50-45° |

BT50-45° |

|

Drive feed |

||||

|

Maximum rapid movement speed X/Y/Z |

m/min |

10/10/10 |

10/10/10 |

10/10/10 |

|

Maximum cutting speed X/Y/Z |

m/min. |

6/6/6 |

6/6/6 |

6/6/6 |

|

Minimum resolution |

mm |

0.001 |

0.001 |

0.001 |

|

Accuracy (implementation standard GB/T19362.1-2003) |

||||

|

X/Y/Z Positioning accuracy |

mm |

0.03 |

0.03 |

0.05 |

|

X/Y/Z Repeatability |

mm |

0.02 |

0.02 |

0.03 |

|

Others |

||||

|

CNC system |

|

FANUC Oi MF(5) |

FANUC Oi MF(5) |

FANUC Oi MF(1) |

|

power |

kW |

60 |

60 |

75 |

|

Machine height |

mm |

3300 |

3300 |

4200/4200/4700 |

|

Foolr Area (length*witdth) |

mm |

6600*4300 |

5600*4500 |

6000*4500/7000*4500/7000*4500 |

|

Machine weight (approx.) |

kg |

15000 |

20000 |

25T/28T/32T |

Configuration Intro

(1)FANUC 0i-MF(1)

Standard FANUC Oi-MF One CNC System, high processing performance high operating rate, high ease of use.At the same time, SIEMENS/Mitsubishi CNC system can be selected according to needs.

(2)Spindle

BT50 spindle with high speed, high efficiency, high torque processing characteristics, to meet the processing needs of a variety of typical materials.

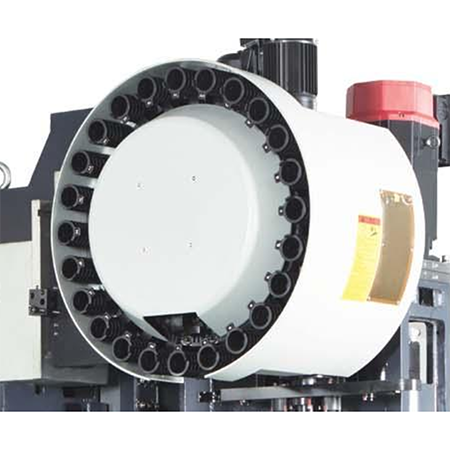

(3)Tool Magazine

CNC horizontal machining center with standard 24T tool magazine can be equipped with 40/60T tool magazine according to actual processing needs to meet customers' various cutting scenarios.

Table Type Horizontal Machining Center

X / Z axis is a linear guideway,Y axis is a hard guideway.

The spindle box is full-gear structure, with large torque.

High cost performance, suitable for rough and semi finish machining.

Moving Column Heavy Roughing Horizontal Machining Center

Moving column structure.

X / Z axis is a linear guideway, Y axis upgraded to hard guideway, Y-axis column rigidity enhancement.

Gearbox upgrade, cutting efficiency greatly improved.

Upgrade to a new type of shield.

The spindle speed is upgraded to 4500 rpm.

Floor Type CNC Horizontal Machining Center (heavy roughing machine)

Heavy-duty cutting and heavy-load, a sharp tool for roughing and semi-finishing, durable.

Floor-standing structure, large load-bearing capacity.

Full gear 10-3000 revolutions, torque can reach more than 1000N.m.

Ram can extend 700mm for processing.

A sharp tool for roughing and semi-finishing automobile molds. .

The motor torque is increased by 30-37kw, the gear is enlarged, the strip structure is optimized, and the cutting force is greatly enhanced.

|

Item |

H B 1 7 1 2 ( Worktable type ) |

H B 1 8 1 2 (Moving column type ) |

HB2516/HB3016/HB3020(Floor-standing type) |

|

|

Processing range |

||||

|

X-axis travel |

mm |

1700 (the worktable moves left and right) |

1800 (the worktable moves left and right) |

2500/3000/3000 (column moves left and right) |

|

Y-axis travel |

mm |

1200 (the spindle box moves up and down) |

1200 (the spindle box moves up and down) |

1600/1600/2000 (spindle box moves up and down) |

|

Z-axis travel |

mm |

700 (the worktable moves forward and backward) |

800 (the column moves forward and backward) |

700 (ram extends forward and backward) |

|

Spindle center to table |

mm |

0-1200 |

130-1330 |

100-1700/100-1700/100-2100 |

|

Spindle end face to table center |

mm |

150-850 |

200-1000 |

200 |

|

Guide rail type |

XZ axis linear guide/Y axis hard guide |

XZ axis linear guide/Y axis hard guide |

||

|

Worktable |

||||

|

Worktable dimensions |

mm |

1700*850 |

1600*1000 |

2500*1550/3000*1550/3000*1550 |

|

Worktable load bearing |

kg |

5000 |

8000 |

30000 |

|

T-slot specifications (width*spacing) |

mm |

18*150 |

22*150 |

22*200 |

|

Spindle |

||||

|

Drive mode |

Full gear |

Full gear |

Full gear |

|

|

Maximum speed |

rpm |

3000 |

4500 |

3000 |

|

Spindle power |

kW |

15/18.5 |

15/18.5 |

30/37 |

|

Maximum spindle torque |

N.m |

286/472 |

473/894 |

498/748 |

|

Spindle taper/pull pin |

BT50-45° |

BT50-45° |

BT50-45° |

|

|

Drive feed |

||||

|

Maximum rapid movement speed X/Y/Z |

m/min |

10/10/10 |

10/10/10 |

10/10/10 |

|

Maximum cutting speed X/Y/Z |

m/min. |

6/6/6 |

6/6/6 |

6/6/6 |

|

Minimum resolution |

mm |

0.001 |

0.001 |

0.001 |

|

Accuracy (implementation standard GB/T19362.1-2003) |

||||

|

X/Y/Z Positioning accuracy |

mm |

0.03 |

0.03 |

0.05 |

|

X/Y/Z Repeatability |

mm |

0.02 |

0.02 |

0.03 |

|

Others |

||||

|

CNC system |

FANUC Oi MF(5) |

FANUC Oi MF(5) |

FANUC Oi MF(1) |

|

|

power |

kW |

60 |

60 |

75 |

|

Machine height |

mm |

3300 |

3300 |

4200/4200/4700 |

|

Foolr Area (length*witdth) |

mm |

6600*4300 |

5600*4500 |

6000*4500/7000*4500/7000*4500 |

|

Machine weight (approx.) |

kg |

15000 |

20000 |

25T/28T/32T |