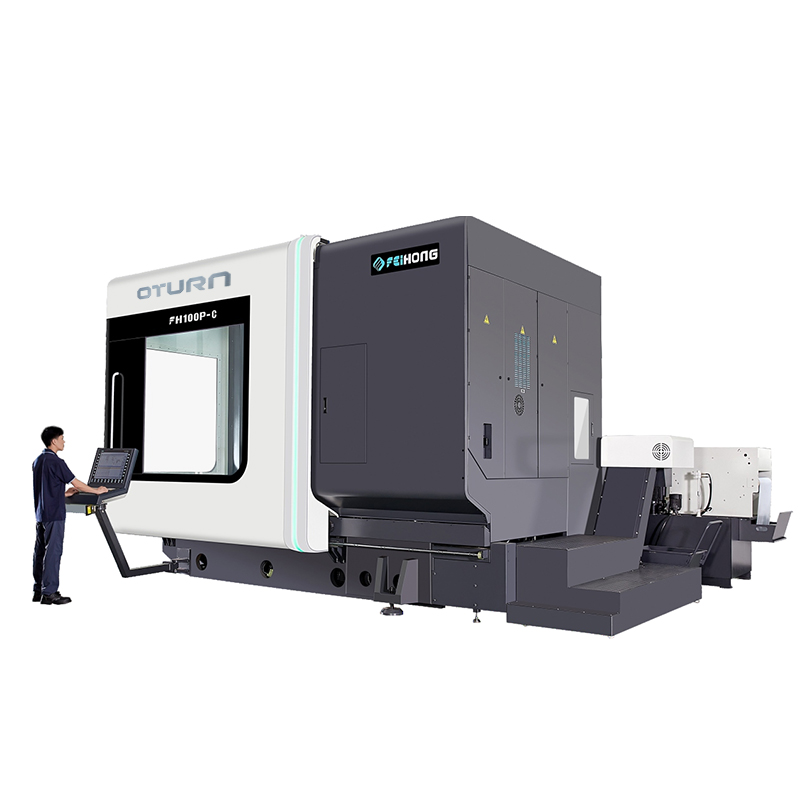

CNC Hobbing Manufacturer in China: Precision Engineering Solutions

As a manufacturer based in China, I’m excited to share our precision CNC hobbing services designed for exceptional quality and efficiency. Our CNC hobbing machines are capable of producing intricate gear teeth profiles with high accuracy, making them perfect for various applications across industries. We understand the importance of tight tolerances and quick turnaround times, especially for B2B partners who rely on us for timely deliveries. Our dedicated team of experts ensures that every piece meets strict quality standards, using advanced technologies to streamline the manufacturing process. Partnering with us means gaining access to customized solutions that cater to your specific needs, whether you require small batch runs or large scale production. Let us help you optimize your production with our reliable CNC hobbing services. Your satisfaction is our top priority, and we're here to provide you with exceptional service every step of the way.

Cnc Hobbing Market Leader Exceeds Industry Benchmarks

In the rapidly evolving landscape of the CNC hobbing market, achieving excellence and exceeding industry benchmarks is crucial for success. Leading manufacturers are continuously innovating to enhance precision, efficiency, and reliability in their processes. This not only benefits the manufacturers but also provides global procurement specialists with the assurance that they are investing in high-quality machinery that meets stringent operational standards. With cutting-edge technology and advanced engineering methodologies, industry leaders are setting new benchmarks that redefine productivity in gear manufacturing. This commitment to quality ensures that clients receive machinery that not only meets but often surpasses their expectations for performance and durability. As the demand for high-precision components continues to rise in various sectors, including automotive and aerospace, partnering with these market leaders becomes critical for procurement decisions. Furthermore, sustainability and cost-effectiveness have become central themes in the CNC hobbing sector. By leveraging innovative production techniques and optimizing resource utilization, leading manufacturers are able to offer solutions that align with the global push for environmental responsibility. Global buyers are finding that by sourcing from top-tier firms, they not only gain access to the best technology available but also align themselves with practices that adhere to sustainability principles.

Cnc Hobbing Market Leader Exceeds Industry Benchmarks

| Dimension | Value | Industry Benchmark | Performance Status |

|---|---|---|---|

| Market Share (%) | 32 | 25 | Exceeds |

| Annual Revenue (Million $) | 120 | 100 | Exceeds |

| Production Efficiency (%) | 85 | 78 | Exceeds |

| Customer Satisfaction (%) | 92 | 90 | Exceeds |

| Innovation Index | 4.5 | 4.0 | Exceeds |

Related Products