China OEM Double Column Cnc Vertical Lathe - Valve Automatic Machining line – Oturn

China OEM Double Column Cnc Vertical Lathe - Valve Automatic Machining line – Oturn Detail:

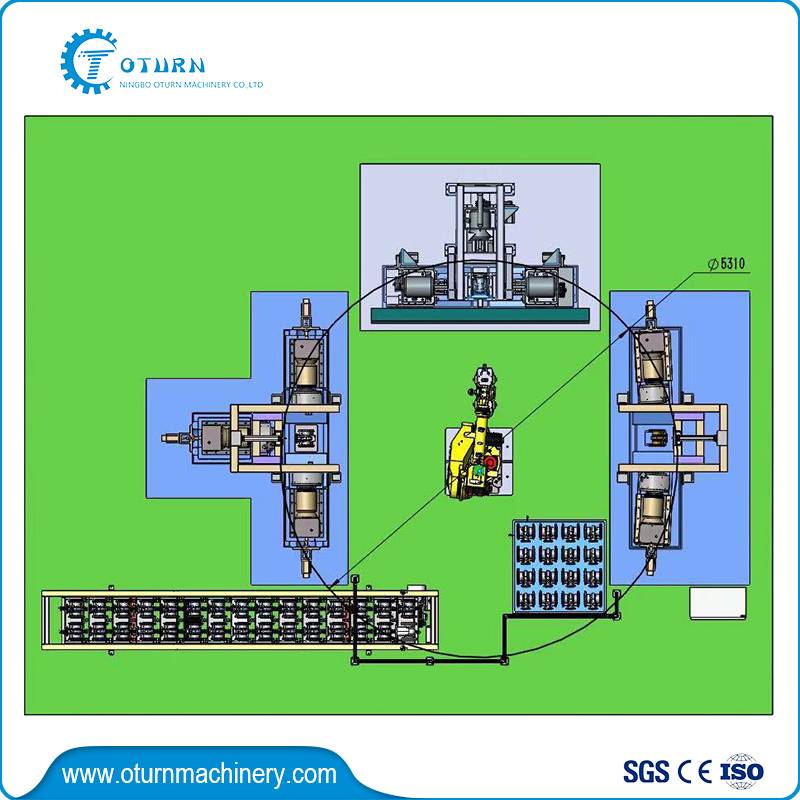

Whole layout

1: This automation equipment is composed of a six-axis machining center, a multi-axis machining center, and a four-axis machining center (different equipment can be configured according to customer needs); a robot is configured for loading and unloading.

2: The layout of the processing area is semi-enclosed, and only the inlet and outlet are set up at the upper and lower motorized track positions, which are used for loading and unloading the valve bodies.

3: The loading and unloading can be fed by the feeder or the vision robot.

Partial automation details

1.The loading and unloading robot can choose international or domestic well-known brands to meet the travel and load requirements of this automatic loading and unloading;

2.The equipment adopts full protection, with a dust removal device, the protection door is automatically pushed and pulled according to instructions, and the tooling is automatically clamped and chipped.

3.After the processing is completed, the workpiece is directly placed on the conveyor belt by the robot and transported to the next process.

4.The robot gripper is designed with double grippers, which can be used alternately to complete the loading and unloading of the machine.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,