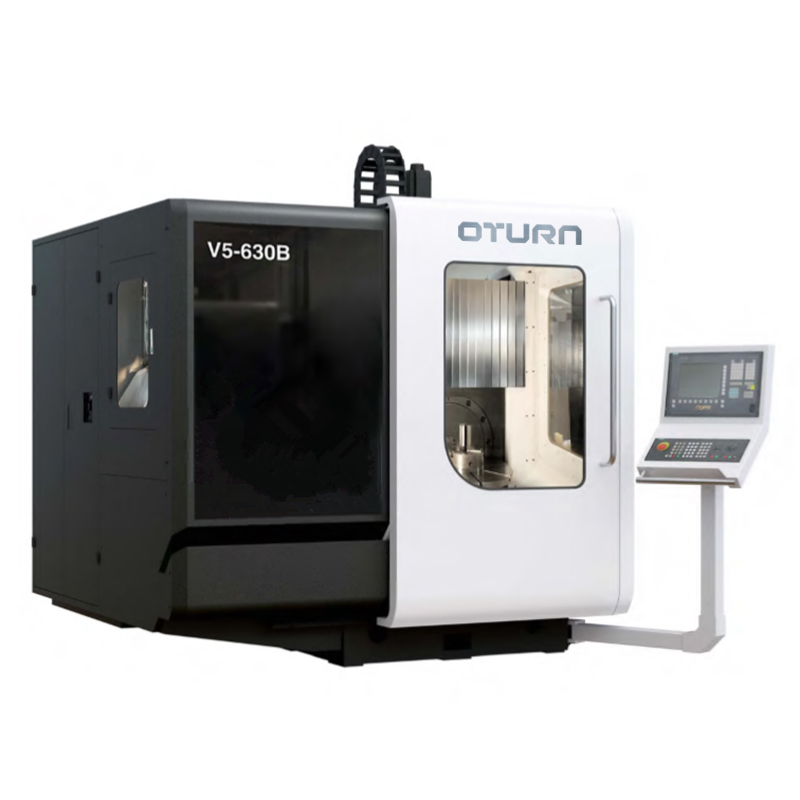

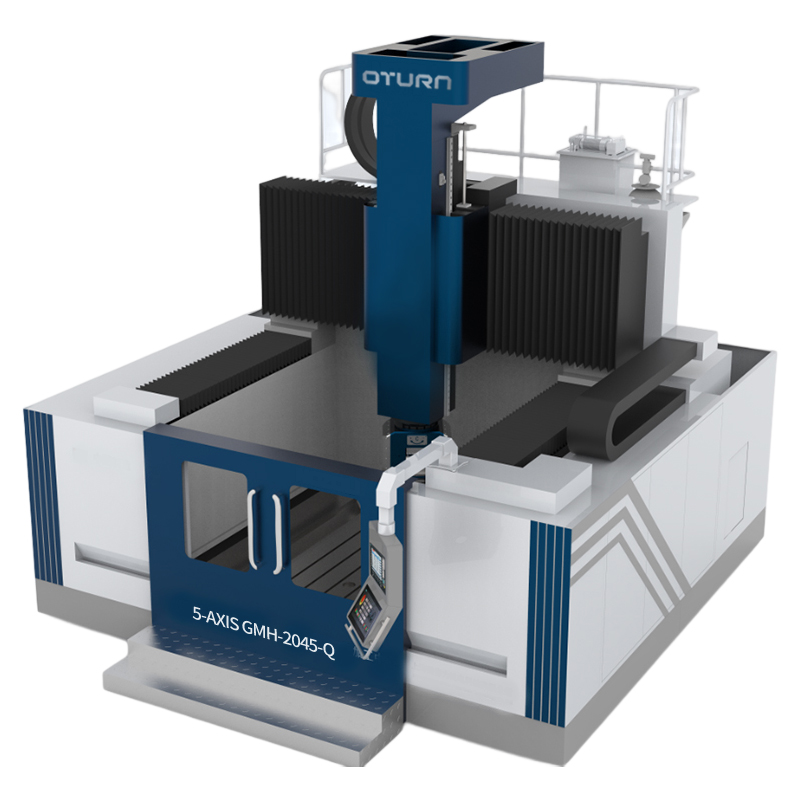

Top China Manufacturer of 5 Axis CNC Lathe for Precision Machining

When it comes to precision machining, our 5 Axis CNC Lathe is a game changer. Designed for manufacturers in China who demand high accuracy and efficiency, this machine offers unparalleled flexibility in complex part production. With its ability to operate on multiple axes simultaneously, it significantly reduces setup times and enhances overall productivity. I’ve seen firsthand how this lathe can elevate a manufacturer’s capabilities, allowing for intricate designs and tighter tolerances. The robust construction ensures durability, making it a reliable choice for your production line. If you’re seeking an advanced solution for your manufacturing needs, this 5 Axis CNC Lathe might be just the partner you need. It's not just about making parts; it's about making them better and faster. Let’s enhance your manufacturing process today!

5 Axis Cnc Lathe Custom Solutions, Where Service Meets Innovation

In today's competitive manufacturing landscape, the demand for precision, efficiency, and customization is at an all-time high. Our 5-axis CNC lathe solutions stand at the intersection of service and innovation, designed specifically to meet the unique needs of global buyers. These advanced machines enable intricate machining processes, allowing for complex designs that were once challenging or impossible to achieve. The ability to perform multiple operations in a single setup drastically reduces processing time and enhances productivity, making them an invaluable asset for any production line. We understand that each buyer has distinct requirements, which is why our custom solutions are tailored to fit various industry applications, from aerospace to automotive and beyond. By leveraging cutting-edge technology and expert engineering, we guarantee not only superior performance but also seamless integration into existing manufacturing workflows. Our commitment to customer satisfaction extends beyond the sale, with comprehensive support services that ensure smooth operation and maintenance of your CNC lathe. Investing in our 5-axis CNC lathe solutions means partnering in innovation. As we prioritize user experience and ongoing development, our clients benefit from continuous improvements that keep pace with industry advancements. Join us in redefining manufacturing standards; let us help you turn your ambitions into reality with our exceptional CNC solutions that combine reliability, efficiency, and unparalleled service.

5 Axis Cnc Lathe Custom Solutions, Where Service Meets Innovation

| Feature | Description | Applications | Benefits |

|---|---|---|---|

| High Precision | Offers micron-level accuracy in machining. | Aerospace components, medical devices. | Reduces material waste and enhances product quality. |

| Flexible Design | Custom solutions for a variety of designs. | Automotive parts, custom tooling. | Meets unique customer demands and specifications. |

| Multi-Axis Capability | Allows complex geometries to be machined. | Industrial equipment, precision instruments. | Increases design possibilities and reduces setup time. |

| Automated Processes | Incorporates automation for efficiency. | High-volume production runs. | Reduces labor costs and increases throughput. |

| Innovative Technology | Utilizes the latest CNC machining technologies. | Electronics, consumer goods. | Enhances product performance and reliability. |

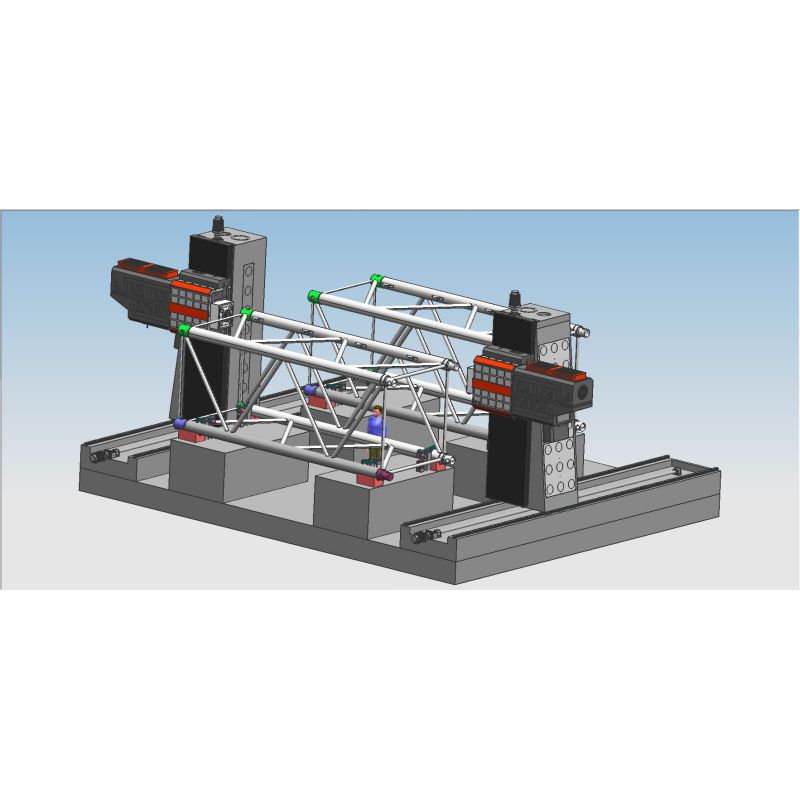

Related Products