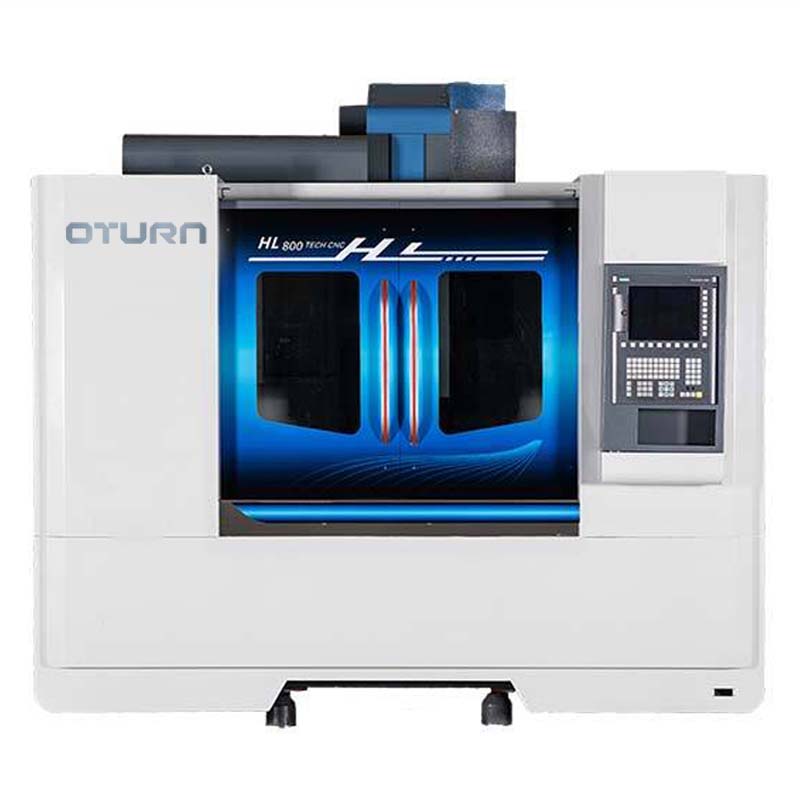

High-Quality Vertical Machining Center from Leading China Manufacturer

As a seasoned manufacturer of Vertical Machining Centers in China, I understand the high standards and demands of B2B purchasers like you. Our machines are crafted with precision and designed to enhance productivity in various industries. With state-of-the-art technology, these centers ensure superior accuracy and efficiency, making them ideal for complex machining tasks. When I use our Vertical Machining Centers, I see firsthand how they revolutionize operations by reducing setup time and increasing throughput. Our commitment to quality means you can trust in the durability and reliability of our products. With customizable options, we can meet your specific needs whether you’re in automotive, aerospace, or any manufacturing sector. I invite you to join countless satisfied clients who have improved their manufacturing processes with our machines. Together, we can build a partnership that propels your business forward. Let’s take your production capabilities to the next level with our exceptional Vertical Machining Centers.

Vertical Machining Center Factory-Direct Excellence Service Backed by Expertise

In today's fast-paced manufacturing landscape, the importance of precision machining cannot be overstated. Vertical machining centers (VMCs) stand at the forefront of this technological evolution, offering unparalleled capabilities for a wide range of applications. As global demand continues to rise for efficient and highly accurate machining, finding a supplier that combines quality, service, and expertise becomes crucial for procurement specialists. Partnering directly with a manufacturer can significantly enhance your operational efficiency. Factory-direct services ensure that you gain access to the latest advancements in machining technology without the added overhead costs of intermediaries. This model not only streamlines the procurement process but also provides customers with direct insights and support, enabling them to make informed decisions that can lead to optimized production lines and increased profitability. With seasoned professionals behind the scenes, clients can leverage expertise to tailor solutions that meet specific project requirements, ensuring the highest standards of quality and performance. Investing in vertical machining centers is not just about acquiring state-of-the-art machinery; it represents a strategic move towards enhancing productivity and efficiency. A solid partnership with a manufacturer offering excellence in service leads to long-term growth and operational success. As you explore your options in the global market, prioritize suppliers that showcase their commitment to both quality and customer satisfaction, ensuring you have the support needed for every aspect of your machining endeavors.

Vertical Machining Center Factory-Direct Excellence Service Backed by Expertise

| Feature | Description | Benefit |

|---|---|---|

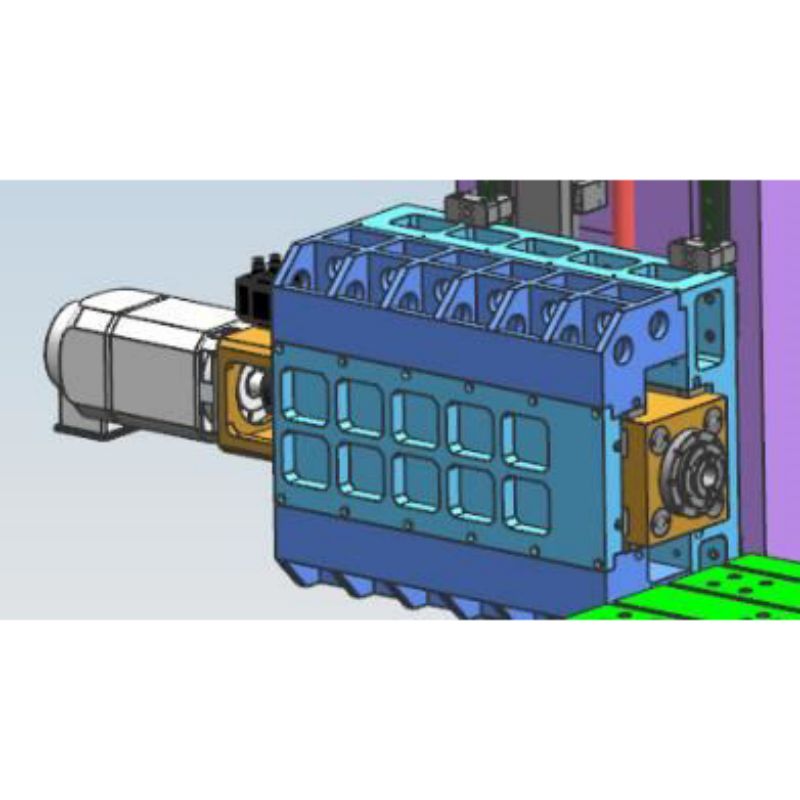

| High Precision | Utilizes advanced linear guideways and ball screws | Increased accuracy for complex machining tasks |

| User-Friendly Interface | Intuitive touchscreen display for easy operation | Reduced training time for operators |

| Versatile Tooling | Compatible with various tool types and sizes | Flexibility to handle diverse projects |

| Robust Construction | Built with high-quality materials for durability | Longer lifespan reducing the need for frequent replacements |

| Quick Setup | Designed for easy and fast installation | Minimized downtime for production |

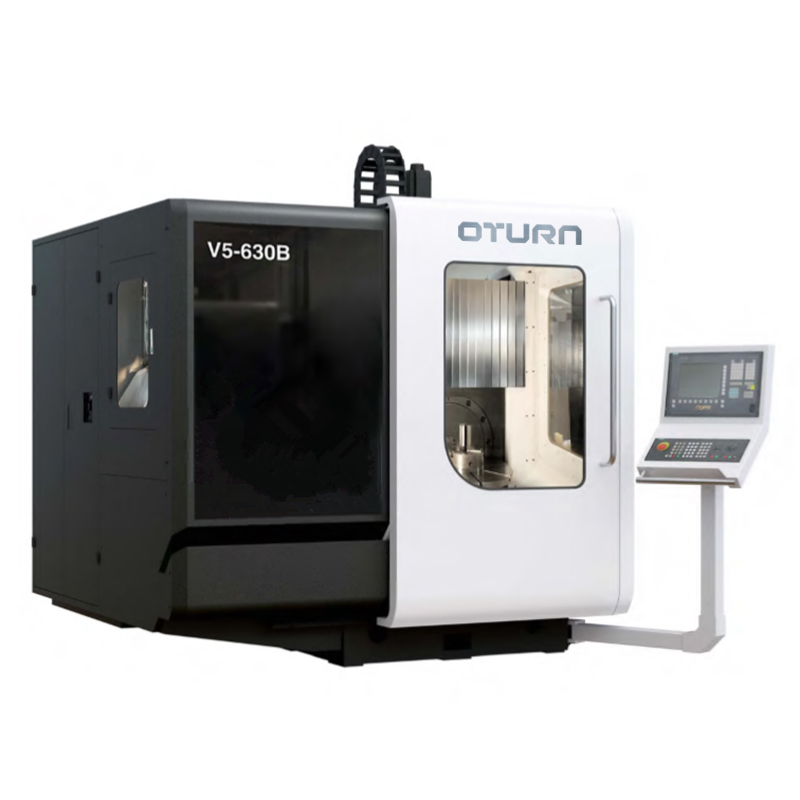

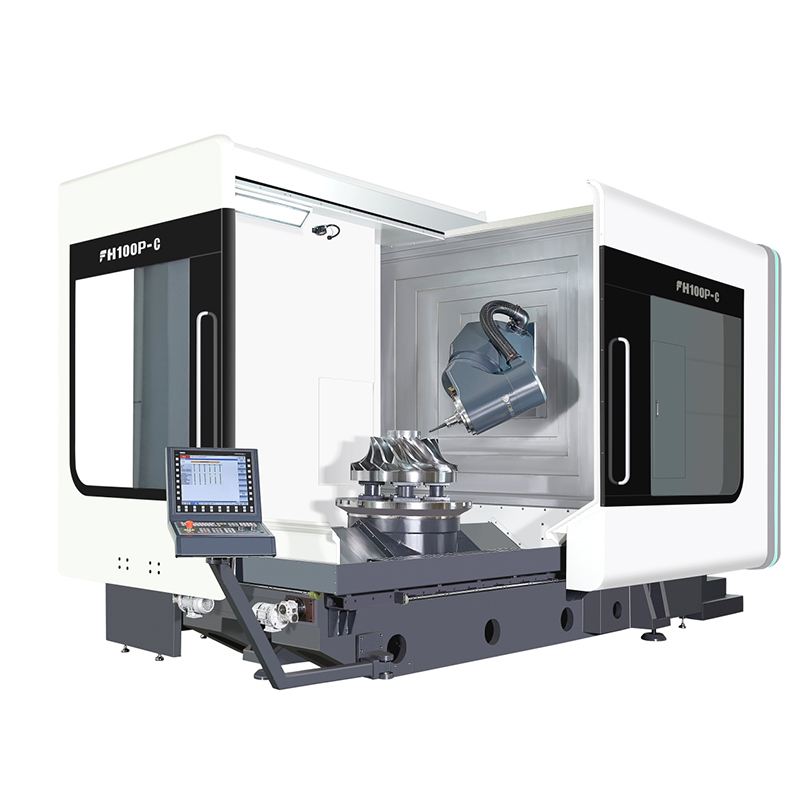

Related Products