Top China Manufacturer of Vertical CNC Lathe Machines for Precision Machining

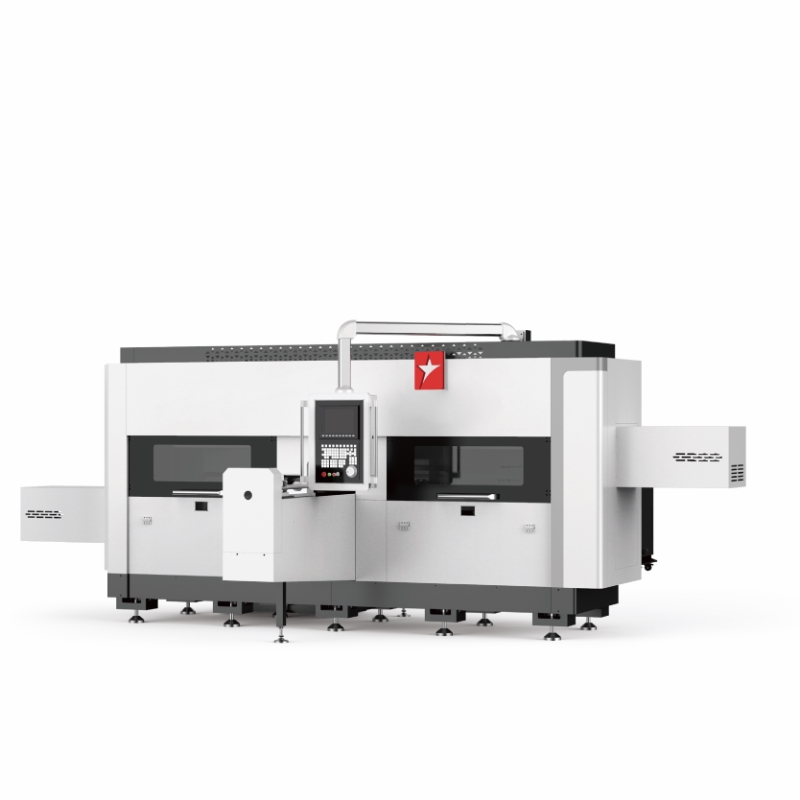

If you’re in the market for a Vertical CNC Lathe Machine, you’ve come to the right place. Our machines are designed with precision and efficiency in mind, perfect for various industries. As a manufacturer based in China, we understand the importance of reliability and cutting-edge technology in enhancing your production capabilities. Our Vertical CNC Lathe Machines offer robust performance, allowing you to handle complex machining tasks with ease. With user-friendly controls and customizable options, it's easier for you to adapt the machine to your specific needs. We take pride in delivering high-quality products that meet international standards, ensuring that you’ll get the best value for your investment. Don't miss the opportunity to elevate your manufacturing process. Partner with us to bring innovation and efficiency to your shop floor. Contact us today for more information and to explore how our Vertical CNC Lathe Machines can benefit your business.

Vertical Cnc Lathe Machine Dominates Now Trending

In the rapidly evolving landscape of manufacturing, the vertical CNC lathe machine has emerged as a dominant force, catering to the diverse needs of industries worldwide. Its remarkable precision and efficiency make it an essential tool for companies looking to enhance their production processes. As manufacturers strive for higher accuracy and reduced operational costs, the demand for vertical CNC lathes continues to surge. These advanced machines are particularly beneficial for complex part geometries, allowing for the seamless machining of components with intricate designs. The vertical orientation of the spindle not only improves accessibility but also minimizes the footprint of the machine on the shop floor, optimizing space utilization. Manufacturers across sectors, from automotive to aerospace, are increasingly recognizing the advantages of vertical CNC lathes, leading to their growing popularity in global markets. In addition to their technical capabilities, vertical CNC lathes are equipped with cutting-edge technology that accommodates various materials, ensuring versatility in production. With automation features and smart connectivity, these machines are not just tools but integral components of Industry 4.0 initiatives. As global buyers seek reliable partners in enhancing their manufacturing capabilities, investing in vertical CNC lathe machines represents a strategic move toward achieving operational excellence and maintaining competitive advantage in a challenging market.

Vertical CNC Lathe Machine Dominates Now Trending

| Feature | Specification | Application | Material Compatibility |

|---|---|---|---|

| Spindle Speed | 6000 RPM | Precision Machining | Aluminum, Steel |

| Max Turning Diameter | 800 mm | Heavy-duty Parts | Titanium, Brass |

| Control System | Fanuc | Automotive Components | Carbon Steel, Alloy |

| Tool Type | CNC Cutting Tools | Aerospace Parts | Plastic, Composites |

| Power Consumption | 15 kW | Mold Making | Nickel, Copper |

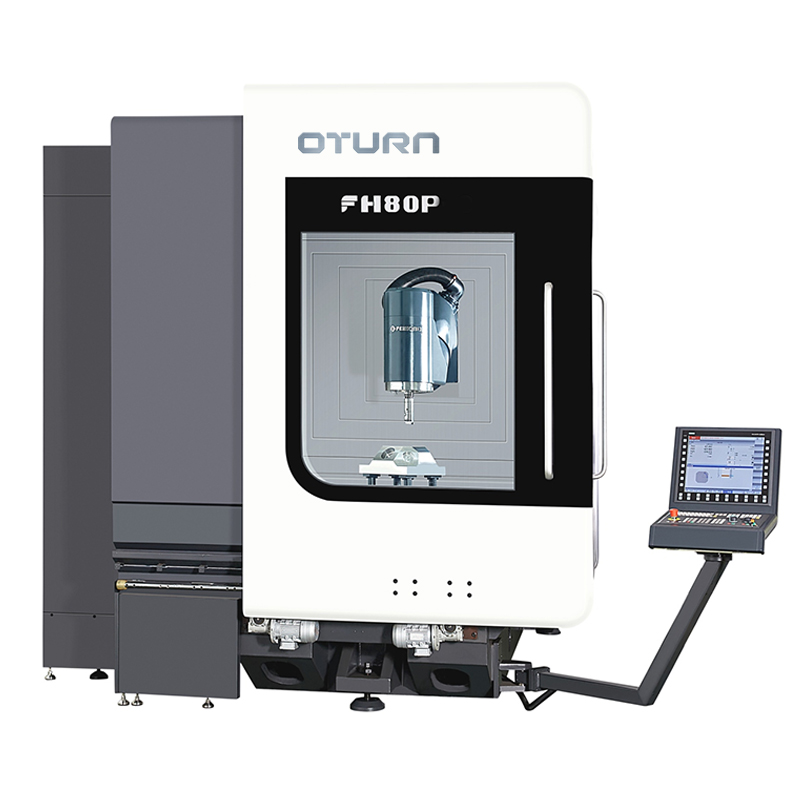

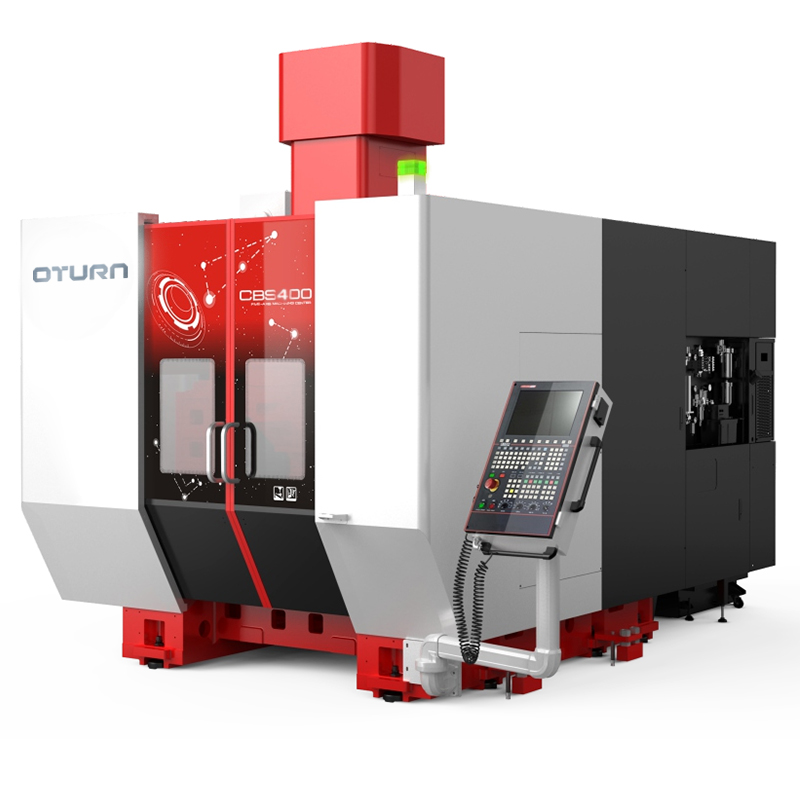

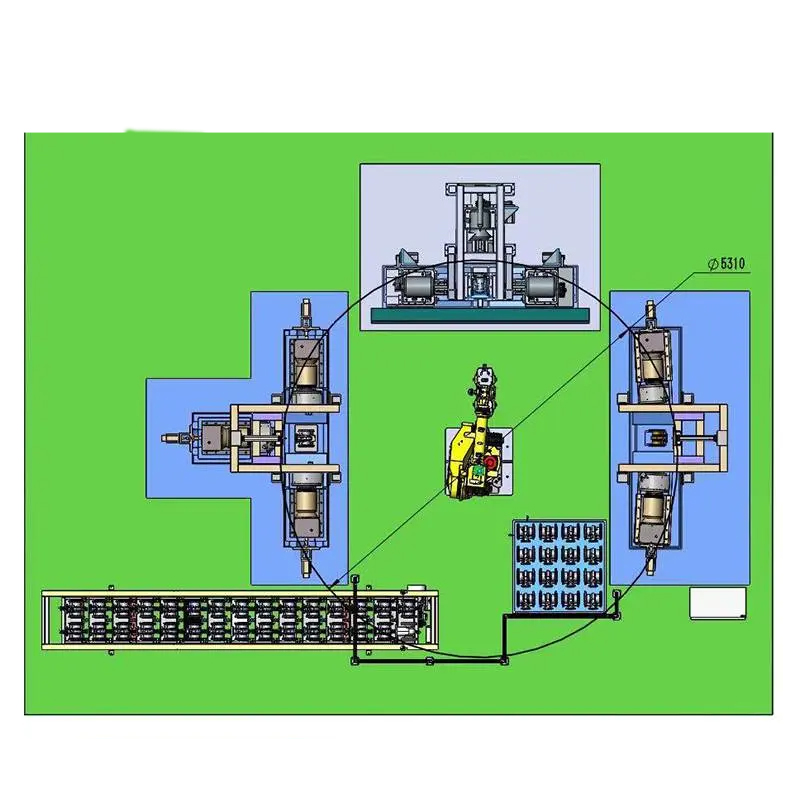

Related Products