Top Valve Machining Manufacturer in China - Quality and Precision

At our facility in China, I specialize in top-notch valve machining, tailoring solutions that meet the unique needs of B2B purchasers. Our dedicated team employs advanced technology and precision engineering to ensure every product is crafted to perfection. Whether you’re in the oil and gas industry or manufacturing sectors, our valves stand up to the toughest conditions and performance standards. Partnering with us means you’re getting more than just a manufacturer; you’re getting a reliable ally who understands the nuances of your business. I understand that quality and efficiency are paramount for your operations, so we prioritize these in every aspect of our valve machining process. With our expertise in custom solutions and commitment to excellence, I’m confident that we can help streamline your production and enhance your product offerings. Let’s connect and explore how our valve machining services can benefit your business today!

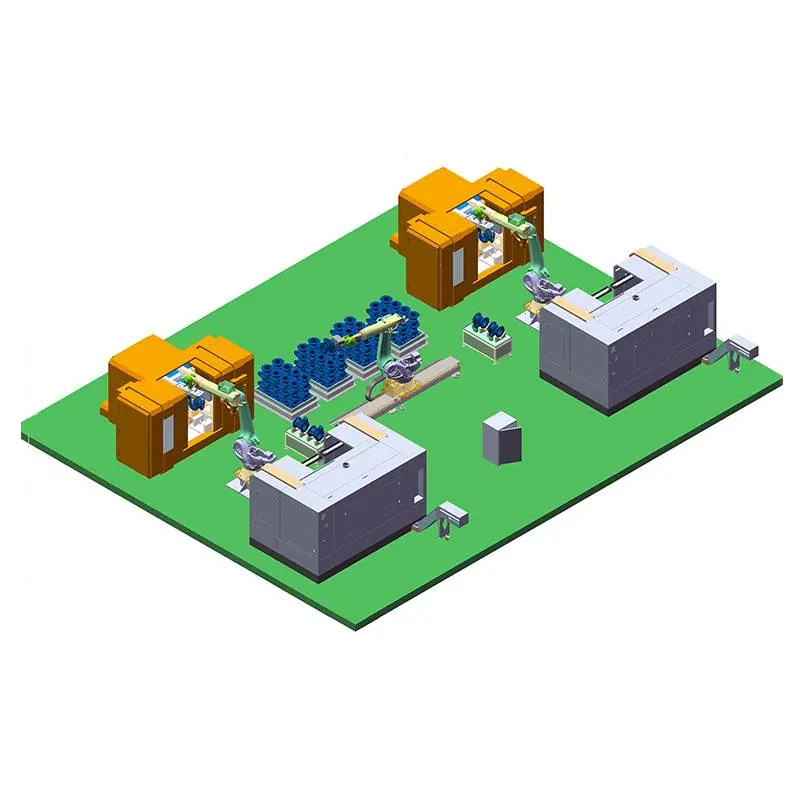

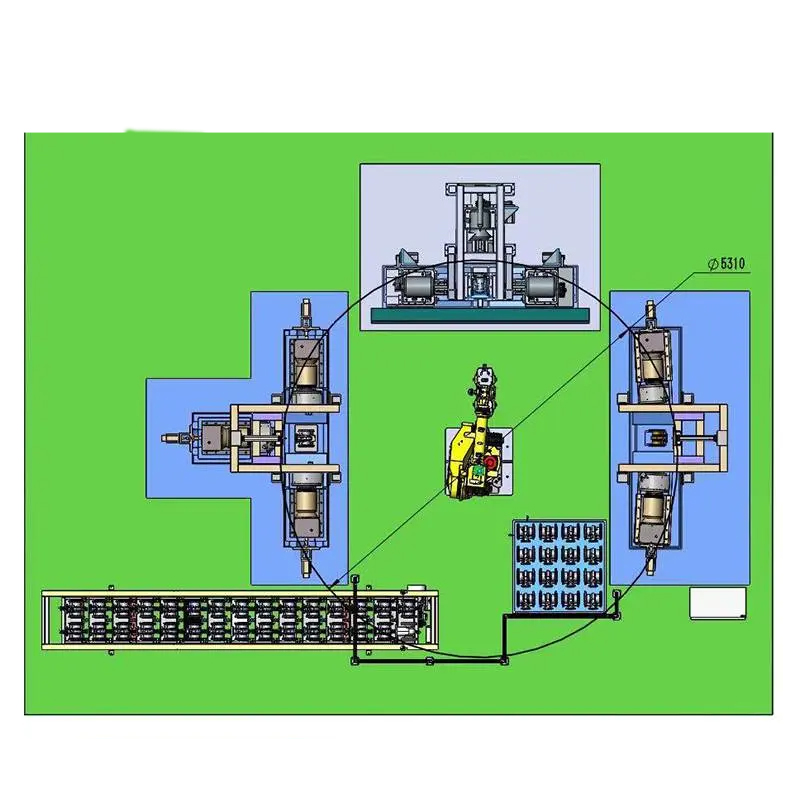

Valve machining Application Your End-to-End Solution

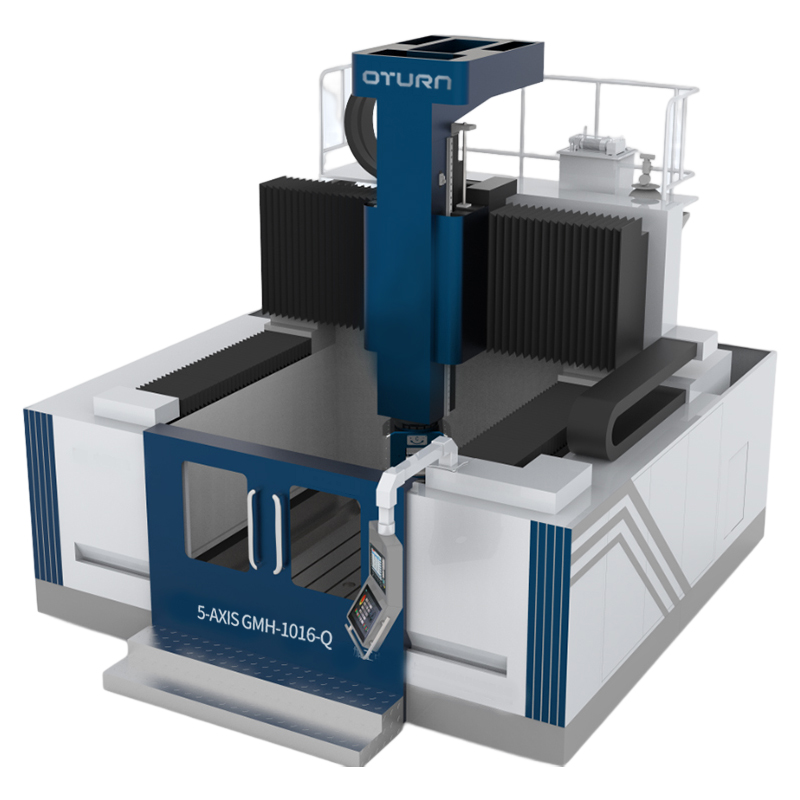

In the rapidly evolving landscape of industrial manufacturing, the demand for precision-engineered components is at an all-time high. Valve machining is an integral part of this process, ensuring that every piece meets strict operational standards. Our end-to-end solutions cater specifically to the needs of global procurement professionals looking for reliability, efficiency, and superior craftsmanship. From initial design through to final production, we leverage advanced machining technologies that guarantee the highest precision and quality, setting the standard in valve manufacturing. Our comprehensive approach streamlines the procurement process, alleviating the common challenges faced by buyers. By integrating design, materials sourcing, machining, and quality control into a single workflow, we provide a hassle-free experience, reducing lead times and costs without compromising on quality. We utilize state-of-the-art machines and employ skilled technicians who are trained in the latest industry standards to ensure that each valve component not only meets but exceeds client specifications. With a commitment to customer satisfaction and continuous improvement, our solutions are tailored to fit diverse industry requirements, from oil and gas to water treatment and beyond. Partnering with us means securing a reliable supply chain for your valve machining needs, allowing you to focus on what matters most—growing your business and maintaining your competitive edge in the market. Embrace the future of valve manufacturing with our expert solutions and experience the difference that precision and quality can make.

Valve Machining Application Your End-to-End Solution

| Application Area | Material Type | Machining Process | Precision Level | Cycle Time (hrs) |

|---|---|---|---|---|

| Oil and Gas | Carbon Steel | CNC Turning | ±0.05 mm | 8 |

| Water Treatment | Stainless Steel | Grinding | ±0.02 mm | 10 |

| Power Generation | Alloy Steel | Milling | ±0.03 mm | 15 |

| Chemical Processing | Titanium | Electrical Discharge Machining | ±0.01 mm | 20 |

Related Products