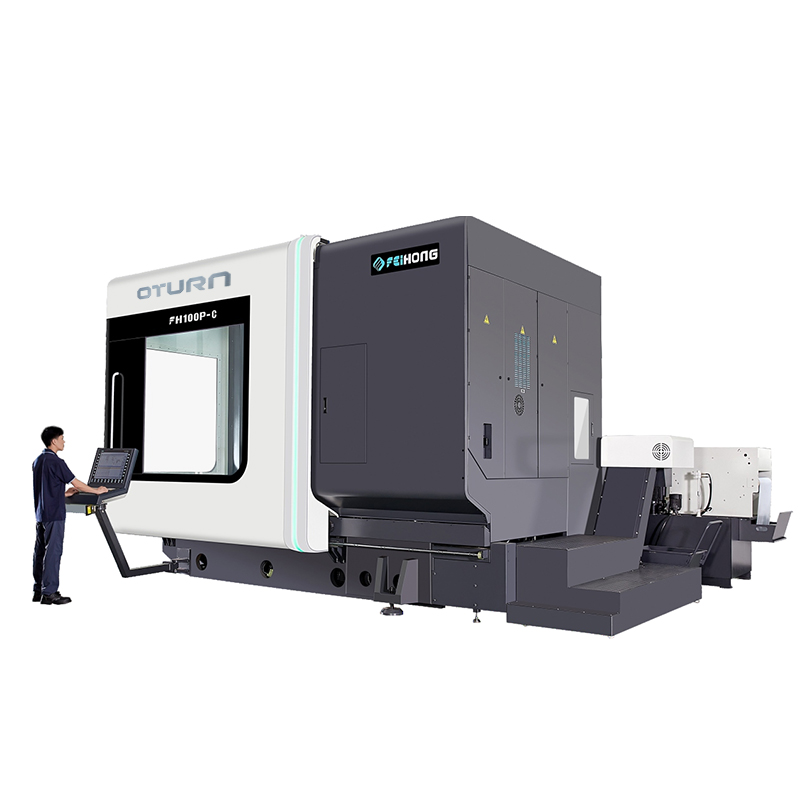

Top China Manufacturer for Precision Valve Body Machining Solutions

When it comes to valve body machining, we understand the critical role it plays in your projects. As a dedicated manufacturer based in China, we take pride in delivering precision-engineered valve bodies that meet high industry standards. Our advanced machining techniques ensure that every component is crafted with attention to detail, offering you reliable performance and durability. We’ve invested in state-of-the-art technology and a skilled workforce to cater to the diverse needs of our clients. Whether you’re in the oil and gas sector or looking for automotive applications, our valve bodies can be customized to fit your specific requirements. I can assure you that our commitment to quality control means you’ll receive products that exceed your expectations. Partnering with us not only means access to top-notch manufacturing capabilities, but also a clear communication process that nurtures long-lasting relationships. Let’s collaborate to elevate your projects with our exceptional valve body machining solutions.

Valve Body Machining Industry Leaders For the Current Year

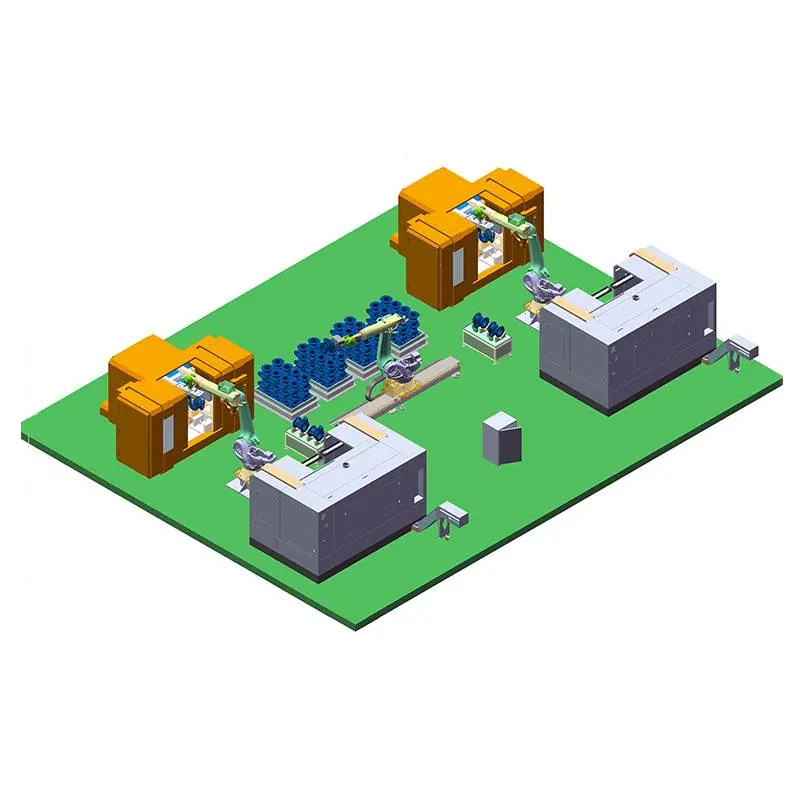

In the dynamic world of valve body machining, industry leaders continue to innovate and adapt to changing market demands. This year has seen significant advancements in technology and processes, enabling manufacturers to produce high-quality, precision-engineered valve bodies that meet the strictest industry standards. As a global buyer, it is crucial to understand the attributes that distinguish top players in this sector, as they leverage modern machining techniques and robust supply chain management to deliver outstanding products. One notable trend is the increasing emphasis on automation and digitalization within machining facilities. By integrating advanced CNC technology and utilizing smart manufacturing practices, industry leaders are not only improving production efficiency but also enhancing quality control. This shift allows for greater customization, reduced lead times, and the ability to respond swiftly to customer requirements in various applications, from automotive to industrial machinery. Another vital aspect is the commitment to sustainable practices in valve body machining. Leading manufacturers are focusing on eco-friendly materials and processes that minimize waste and energy consumption. This commitment not only aligns with global environmental standards but also resonates with an increasingly conscientious consumer base. Investing in partnerships with such industry leaders can provide buyers with a competitive edge, ensuring access to innovative solutions that drive business growth while promoting sustainability in the supply chain.

Valve Body Machining Industry Leaders For the Current Year

| Company | Market Share (%) | Manufacturing Capacity (units/year) | Innovation Index | Sustainability Score |

|---|---|---|---|---|

| Company A | 25 | 500,000 | 8.5 | 90 |

| Company B | 20 | 400,000 | 7.8 | 85 |

| Company C | 18 | 350,000 | 9.0 | 88 |

| Company D | 15 | 300,000 | 8.0 | 82 |

| Company E | 10 | 250,000 | 7.5 | 80 |

Related Products