Top China Manufacturer of Threaded CNC Lathes for Precision Machining

As a leading manufacturer of threaded CNC lathes in China, I understand the importance of precision and reliability in your manufacturing processes. Our threaded CNC lathes are designed to handle complex machining tasks with ease, providing you with the accuracy and efficiency you need to stay competitive. We focus on quality materials and state-of-the-art technology, ensuring each machine delivers consistent performance. With customizable features, our threaded CNC lathes can be tailored to meet your specific production needs, whether you're in automotive, aerospace, or any other industry demanding high-quality machining. Our commitment to customer satisfaction means I’m here to support you every step of the way, from selection to installation. Trust in our expertise and join the many B2B purchasers who have chosen our threaded CNC lathes for their operations. Let's enhance your productivity together!

Threaded Cnc Lathe Sets the Industry Standard Where Service Meets Innovation

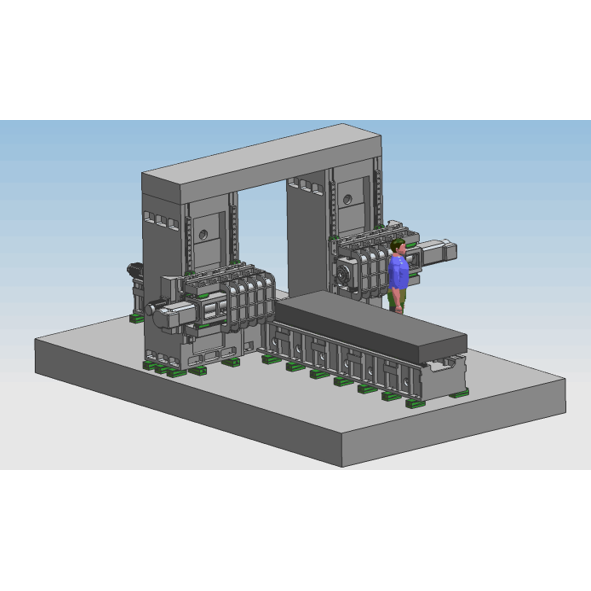

In the ever-evolving landscape of manufacturing, precision and adaptability are critical for success. The introduction of the threaded CNC lathe has set a new benchmark in machining technology, combining outstanding service capabilities with innovative solutions. This state-of-the-art equipment not only enhances productivity but also allows for greater flexibility in production processes, catering to a variety of industries ranging from automotive to aerospace and beyond. End-users are increasingly recognizing the importance of investing in advanced machinery that can streamline operations and reduce downtime. The threaded CNC lathe stands out by offering exceptional accuracy, reduced cycle times, and user-friendly interfaces, making it accessible to both seasoned operators and newcomers. Additionally, its deep integration of smart technology empowers manufacturers to analyze data and optimize machining accordingly, resulting in measurable improvements in efficiency and cost-effectiveness. As global procurement professionals seek suppliers that emphasize innovation and service, the threaded CNC lathe embodies these ideals, providing a reliable solution that meets the demands of modern manufacturing. Investing in this advanced technology not only positions manufacturers at the forefront of their industries but also establishes them as leaders in quality and performance, ensuring they remain competitive in an increasingly global market.

Threaded CNC Lathe Sets the Industry Standard Where Service Meets Innovation

| Feature | Specifications | Benefits | Innovation Aspect |

|---|---|---|---|

| Spindle Speed | 3000 RPM | Enhanced productivity and efficiency | Adaptive speed technology |

| Tooling System | Automatic Tool Changover (ATC) | Reduced manual intervention and downtime | Smart tool management |

| Precision | ±0.01 mm | High-quality outputs with minimal errors | Precision engineering techniques |

| Control System | CNC with Touch Screen Interface | User-friendly operation | Intuitive software design |

| Material Compatibility | Aluminum, Steel, Plastics | Versatile applications across industries | Multi-material processing capability |

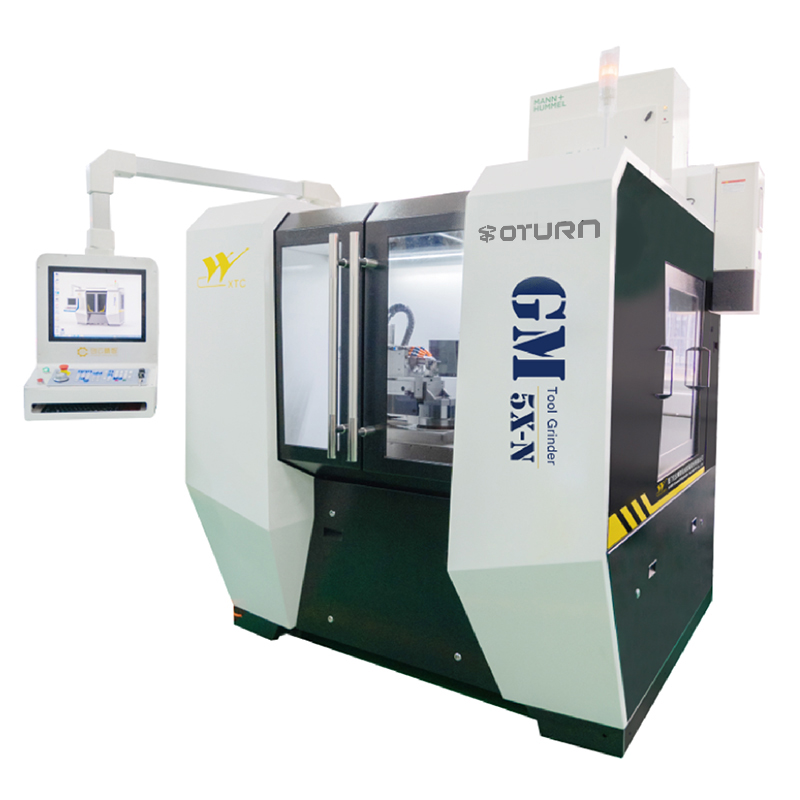

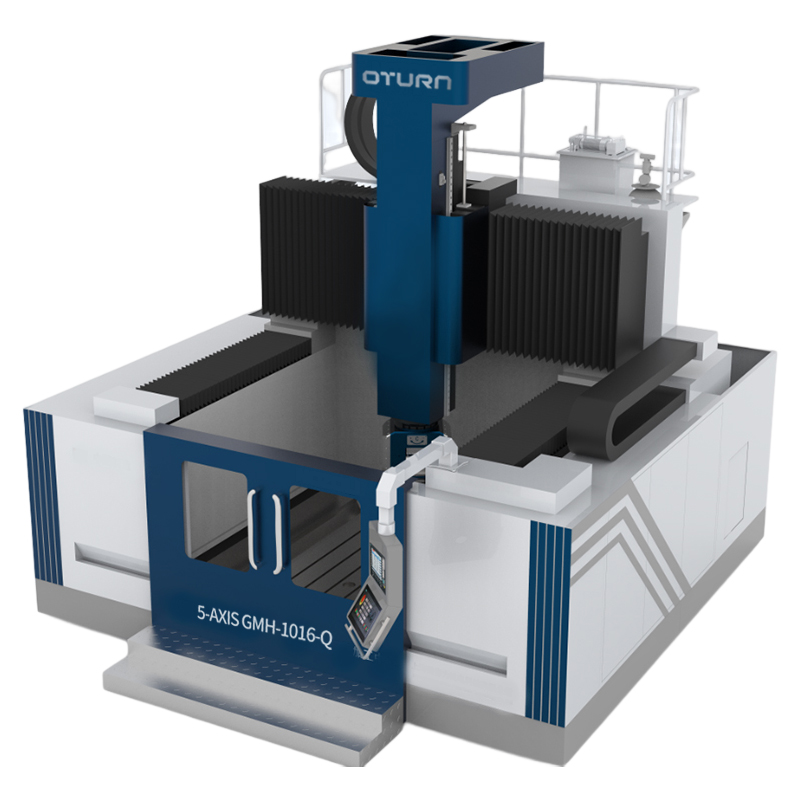

Related Products