Top Slant Bed Lathe Manufacturers in China for Precision Engineering

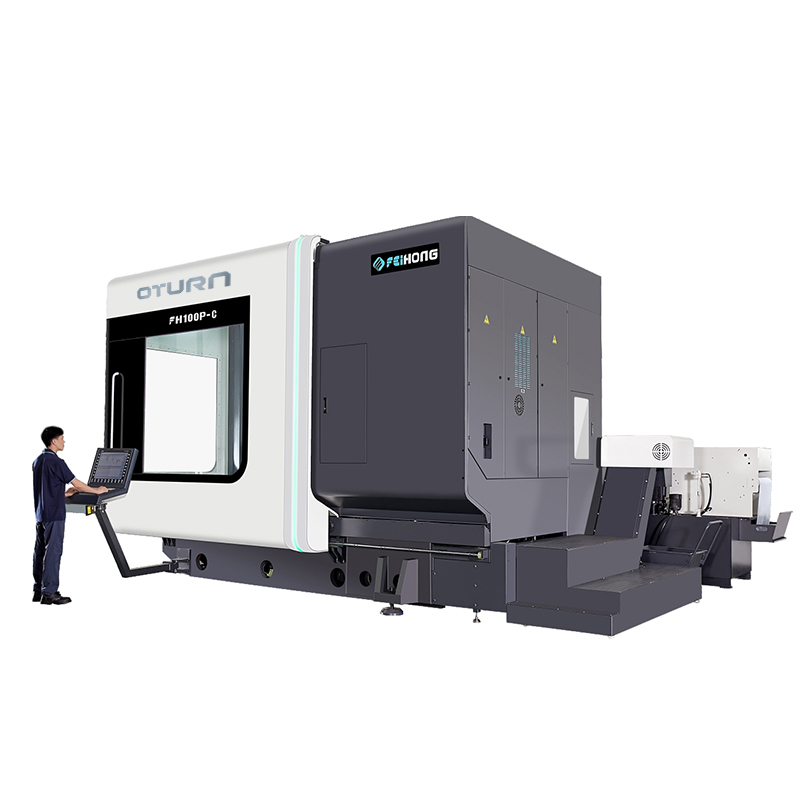

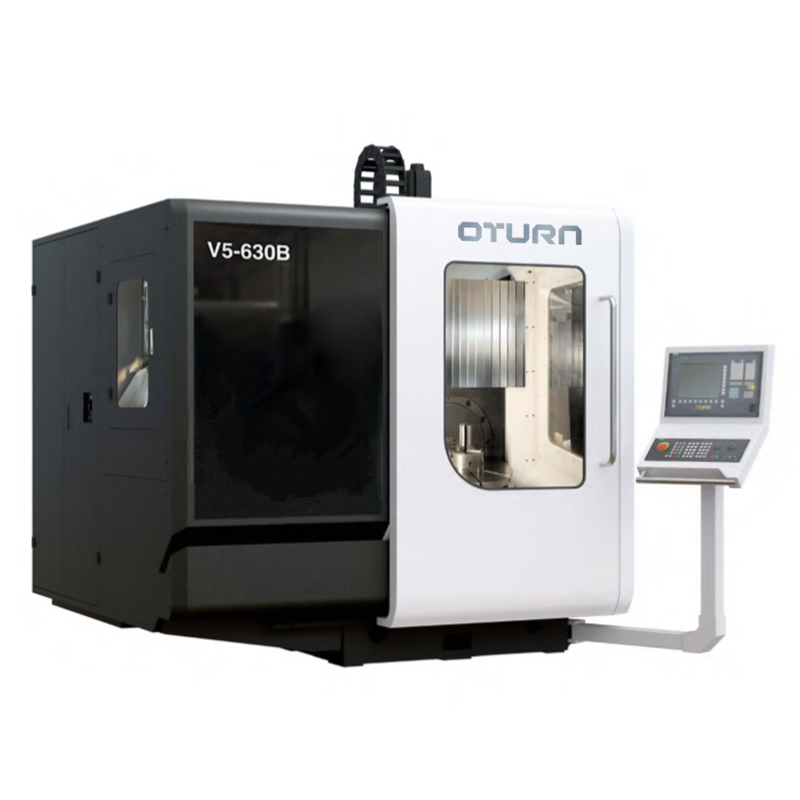

When it comes to precision machining, I’ve found that nothing compares to a Slant Bed Lathe. Designed for efficiency and accuracy, this equipment is essential for any manufacturing setup. As a buyer, I appreciate working with a reliable China manufacturer that understands the nuances of quality and durability. These lathes offer superior rigidity and reduced setup times, making them perfect for high-demand production environments. The ergonomic design enhances operator comfort, which I know is crucial for maintaining productivity over long periods. Plus, with advanced CNC capabilities, the Slant Bed Lathe allows for intricate designs and complex parts to be produced with ease. I can't emphasize enough how crucial it is to partner with a manufacturer that prioritizes both performance and customer support. When you consider purchasing a Slant Bed Lathe, think about the long-term benefits it brings to your operations and the seamless workflow it can create. Your investment will surely pay off!

Slant Bed Lathe For the Current Year Pioneers in the Field

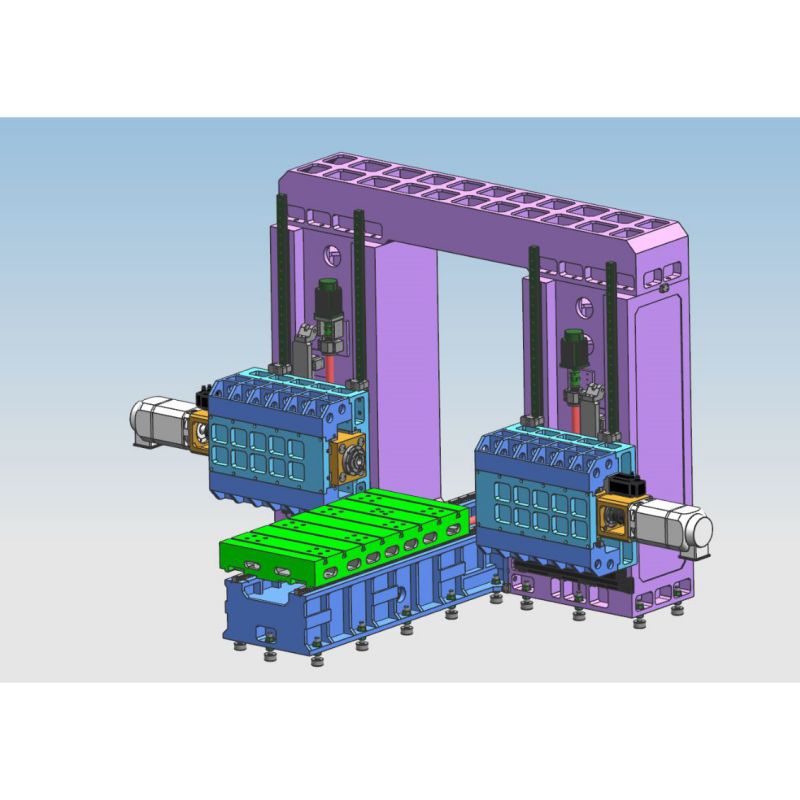

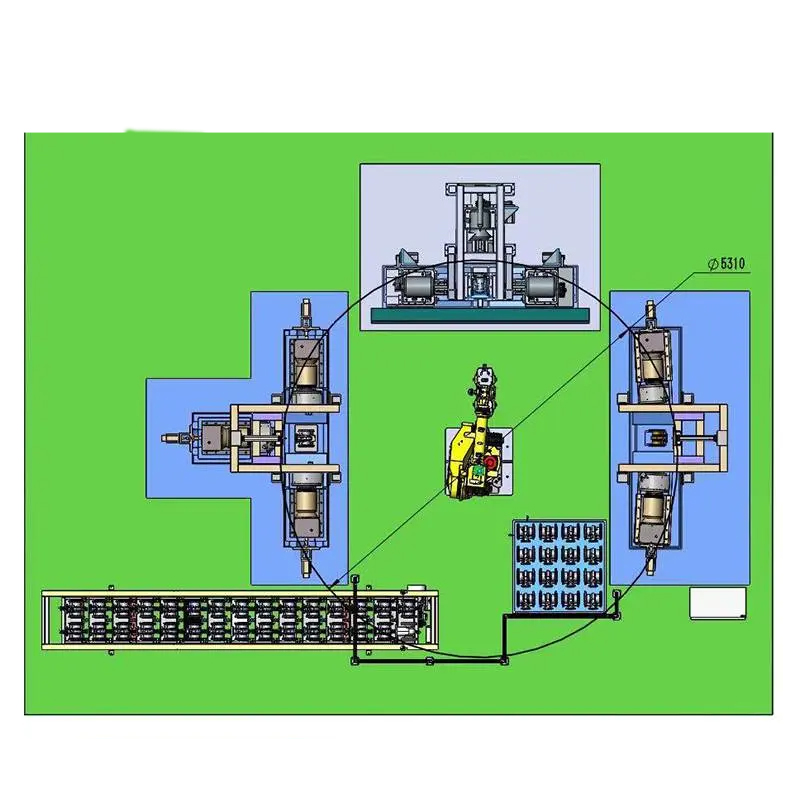

In the ever-evolving landscape of manufacturing, the slant bed lathe has emerged as a vital tool for precision machining and efficiency. For procurement professionals seeking cutting-edge machinery, the advantages of slant bed lathes cannot be overstated. These machines, characterized by their innovative design, offer improved chip removal, reduced friction, and enhanced stability, resulting in superior machining accuracy and faster cycle times. This year, industry leaders are leaning towards these advanced solutions to meet the increasing demands of high-quality production. The latest models of slant bed lathes are equipped with state-of-the-art features, including programmable controls and advanced spindle technology, which further streamline operations. This makes them not only user-friendly but also highly adaptable to different machining needs. As global markets become more competitive, investing in a slant bed lathe can significantly boost productivity and ultimately lead to cost savings, making it an attractive option for manufacturers worldwide. As businesses seek reliable partners in the machinery sector, it is crucial to choose suppliers who offer comprehensive support and a deep understanding of the evolving industry trends. This year’s focus on slant bed lathes reflects a broader shift towards automation and precision in manufacturing, enabling companies to stay ahead of the curve and fulfill rising customer expectations efficiently. Embracing these advancements can provide a competitive edge for enterprises aiming to thrive in a dynamic market environment.

Slant Bed Lathe For the Current Year Pioneers in the Field

| Model | Maximum Swing | Bed Length | Spindle Speed | Control Type |

|---|---|---|---|---|

| SLT-500 | 500 mm | 1000 mm | 3000 RPM | CNC |

| SLT-600 | 600 mm | 1200 mm | 2500 RPM | CNC |

| SLT-700 | 700 mm | 1500 mm | 2200 RPM | CNC |

| SLT-800 | 800 mm | 1800 mm | 2000 RPM | CNC |

| SLT-900 | 900 mm | 2000 mm | 1800 RPM | CNC |

Related Products