News

-

How do valve factories in China formulate operating procedures for valve special machines?

Valve special machines have the characteristics of high efficiency, stability, high precision and long life, which are favored by valve factories. More and more valve factories use valve special machines to produce and process valve workpieces. Let’s take a look at the safety operation rule...Read more -

How to choose CNC machine tool when machining valve parts

Selection principle of CNC machine tools when machining valve parts: ① The size of the machine tool should be compatible with the outline size of the valve to be processed. Large machine tools are used for large parts, so that the equipment can be used reasonably. A vertical lathe should b...Read more -

What Kind Of Workpieces Are Processed By The Horizontal Machining Center?

The horizontal machining center is suitable for processing parts with complex shapes, many processing contents, high requirements, multiple types of ordinary machine tools and numerous process equipment, and multiple clamping and adjustments to complete the processing. The main processing items ...Read more -

Which Industrial Valves Can Be Processed By Our Special Valve Machines?

Our factory produces special valve machines for turning and drilling of forged steel, cast steel (carbon steel) gate valves, globe valves, butterfly valves, etc., with a tool size of 10mm. The equipment is efficient, convenient, stable and reliable. The following valves are introduced for you. We...Read more -

Which Parts Need To Be Paid Attention When The Machining Center Is Maintained?

Machining centers are commonly used equipment in industrial applications for processing metal parts. Generally, a swing table is set on the processing table, and metal parts are placed on the swing table for processing. During the processing, the processing table moves along the guide rail to pro...Read more -

Did You Choose The Right Bit For The CNC Drilling And Milling Machine

The types of drill bits that can be used for CNC drilling and milling machines include twist drills, U drills, violent drills, and core drills. Twist drills are mostly used in single-head drill presses to drill simpler single panels. Now they are rarely seen in large circuit board manufacturers, ...Read more -

What Are The Technological Characteristics Of The Machining Center?

Machining center can summarize some process characteristics as below: 1.Suitable for processing periodic composite production parts. The market demand for some products is cyclical and seasonal. If a special production line is used, the gain is not worth the loss. The processing efficiency with o...Read more -

40 Years Experience In Manufacturing Pipe Thread Lathes Factory.

Pipe Threading Lathe is also called Oil Country Lathe,Our factory,LONWOL,has a team with 40 years experience in the development and manufacture of pipe thread lathes.The first Q1343 and Q1350 pipe threading lathes in China came from our team. As the demand for machine tool market continues to in...Read more -

High-efficiency Industrial Valve Processing Lathe.

Industrial valve processing lathes are also called three-sided or double-sided valve milling machines in our factory. The high-efficiency and high-precision machining requirements of the valve are realized. The special machine tool for simultaneous processing of three sides can perform the requir...Read more -

Tips Before CNC Lathe Operation.

It is the first time for customers in some special regions to come into contact with CNC lathes, and the operation of CNC lathes is still not able to master the machine’s operating skills only from the guidance of the operation manual. Combining the operating experience accumulated by exper...Read more -

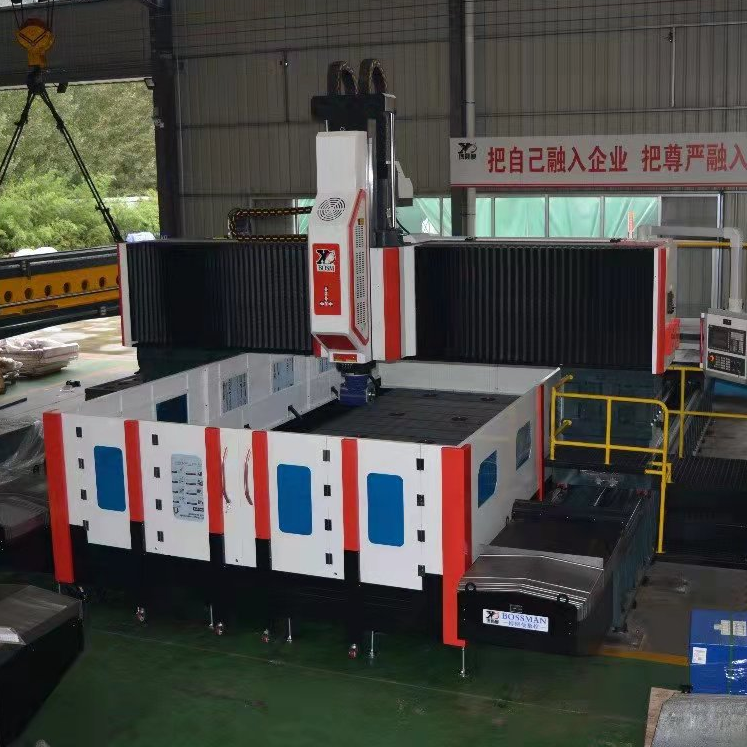

Do You Know The Reason Why The Drill Sleeve Is Not Durable On The Gantry CNC Drilling Machine?

BOSM gantry CNC drilling and milling machine is mainly composed of bed worktable, movable gantry, movable saddle, drilling and milling power head, automatic lubrication device and protection device, circulating cooling device, digital control system, electrical system and so on. With rolling line...Read more -

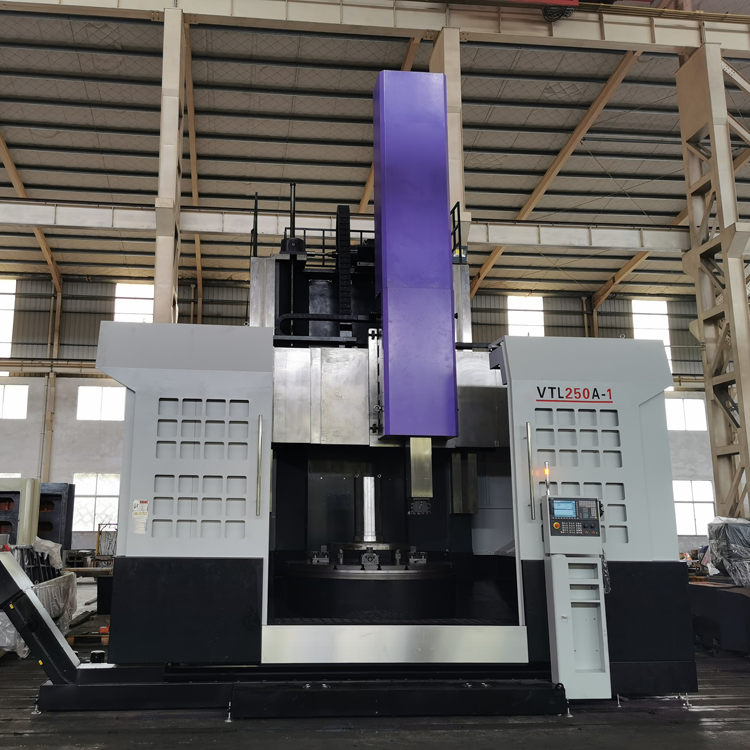

How To Troubleshoot And Maintain Large CNC Vertical Lathes?

Large-scale CNC vertical lathes are large-scale machinery, which are used to process large and heavy workpieces with large radial dimensions and relatively small axial dimensions, and complex shapes. For example, the cylindrical surface, end surface, conical surface, cylindrical hole, conical hol...Read more -

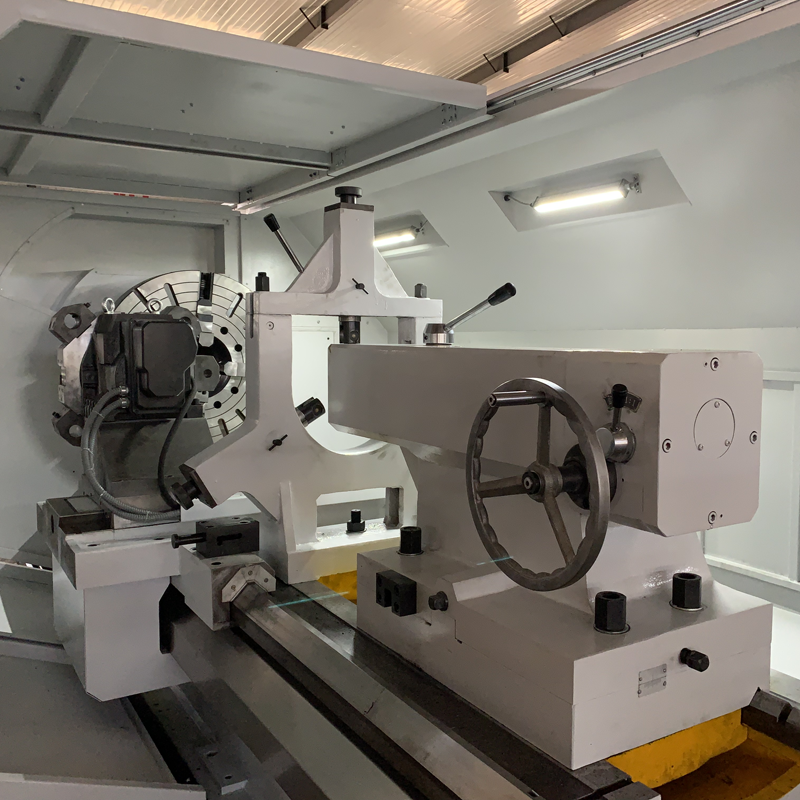

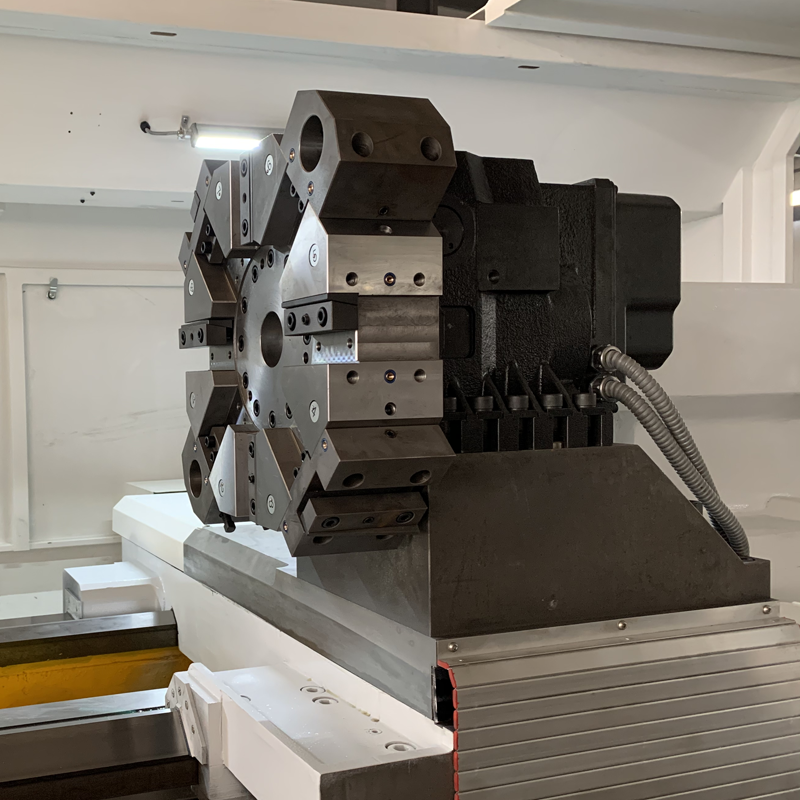

How To Explain The Spindle Of A Pipe Threading Lathe.

The CNC pipe threading lathe can process various thread surfaces and revolving surfaces, and is suitable for turning all kinds of pipe threads. In order to machine the required surface of the workpiece, the tool and the workpiece must maintain accurate relative motion, which is realized by the so...Read more -

A Multi-hole Drill That Increases Your Efficiency By 8 Times

As we all know, in the modern machinery manufacturing industry, enterprises have a wide range of demand for special machine tools. Generally, ordinary drilling machines have high labor intensity, low special performance, low productivity and no guarantee of accuracy; while special multi-hole dril...Read more -

How To Efficiently Drilling Large Tube Sheet Holes?

This article mainly introduces the high-efficiency processing method of large-scale metal tube sheet hole groups used in large-scale reaction vessels and heat exchangers in the petroleum and chemical industries. Choosing traditional boring and milling machines and radial drills has not been able ...Read more