Top China Manufacturer of Manual Vertical Lathes for Precision Machining

When it comes to precision machining, our Manual Vertical Lathe stands out as a reliable solution for your manufacturing needs. As a buyer, you know the importance of quality, and that’s exactly what we deliver. Based in China, we specialize in creating high-performance lathes, designed for both efficiency and durability. Our Manual Vertical Lathes are perfect for various applications, from simple turning tasks to more complex operations. With easy-to-use controls and robust construction, these machines provide the flexibility you need in your workshop. Plus, our expertise as a dedicated manufacturer ensures that each lathe meets stringent quality standards. I’m confident that our Manual Vertical Lathe will exceed your expectations and help streamline your production process. Let’s connect to discuss how our machines can benefit your business and support your growth in the competitive market!

Manual Vertical Lathe Supplier in 2025

As industries continue to evolve, the demand for precise and reliable machining tools has surged, particularly for manual vertical lathes. These machines are essential for various manufacturing processes, offering unparalleled versatility and efficiency in shaping and finishing metal parts. In 2025, the global market for manual vertical lathes is expected to witness notable growth, driven by advancements in automation and a resurgence in domestic manufacturing across several countries. For procurement specialists, collaborating with reliable suppliers becomes crucial. A trusted supplier can offer not only high-quality equipment but also valuable insights into maintenance and optimization practices that can enhance productivity. Businesses looking to source manual vertical lathes should consider factors such as machine specifications, customization options, and after-sales support. Investing in high-performance lathes can lead to improved operational efficiency, reduced downtime, and ultimately, a significant return on investment. As we look toward 2025, it’s essential for buyers to stay informed about new technologies and market trends that could influence their purchasing decisions. Emphasizing partnerships with reputable manufacturers will ensure access to the latest innovations in vertical lathe technology, paving the way for enhanced manufacturing capabilities and competitiveness in an ever-changing marketplace.

Manual Vertical Lathe Supplier in 2025

| Supplier Type | Country | Max Swing Diameter (mm) | Max Distance Between Centers (mm) | Weight (kg) | Power (kW) |

|---|---|---|---|---|---|

| Domestic | USA | 1500 | 3000 | 5000 | 15 |

| International | Germany | 1600 | 3200 | 6000 | 18 |

| Foreign | China | 1400 | 2800 | 4500 | 12 |

| Domestic | Japan | 1550 | 3100 | 5200 | 20 |

| International | Italy | 1700 | 3400 | 6500 | 22 |

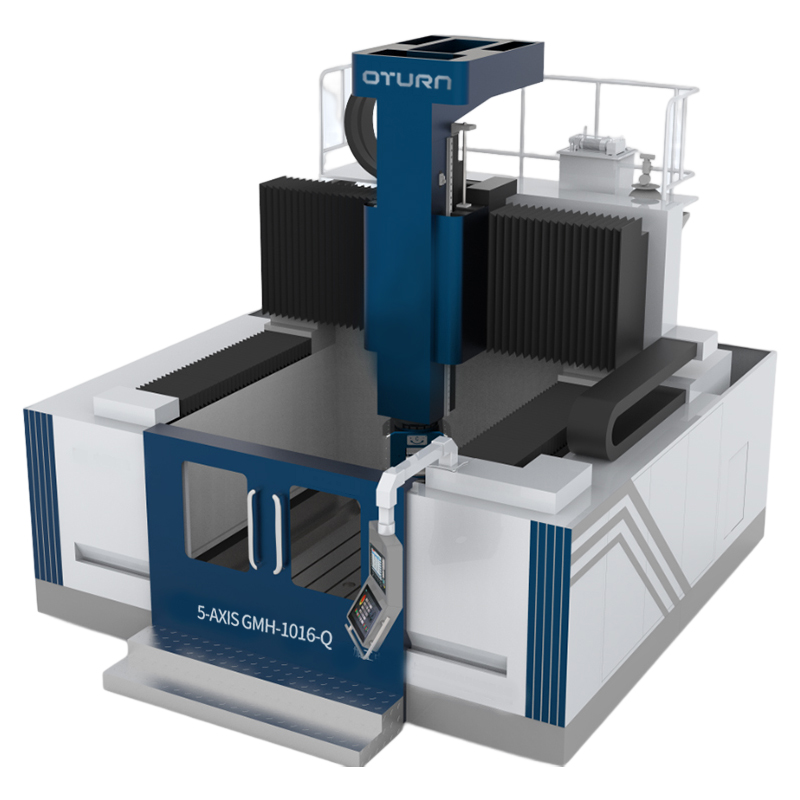

Related Products