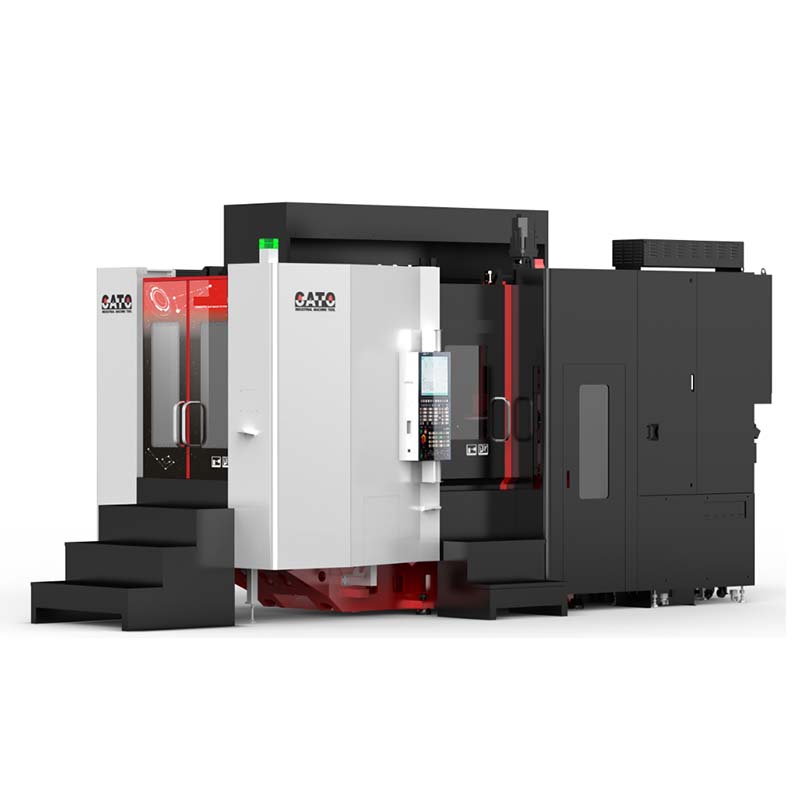

Top China Manufacturer of Horizontal CNC Machining Centers for Precision

When it comes to precision and efficiency in machining, I highly recommend our Horizontal CNC Machining Centers. Designed for optimum performance, these machines excel in high-volume production with unmatched accuracy. As a trusted manufacturer in China, we understand the unique needs of businesses like yours, ensuring our machines are built to withstand rigorous demands while delivering exceptional results. Our Horizontal CNC Machining Centers are equipped with advanced technology, enabling faster cycle times and enhanced productivity. With user-friendly interfaces and durable construction, you can trust that they're built for longevity and easy operation. Whether you’re in aerospace, automotive, or general manufacturing, our centers can adapt to various applications with ease. Choosing the right equipment is crucial for your business success, and I’m here to help you make the best decision. Let’s elevate your manufacturing capabilities with our high-quality CNC machines tailored for today’s competitive market.

Horizontal Cnc Machining Centers Application Manufacturers You Can Rely On

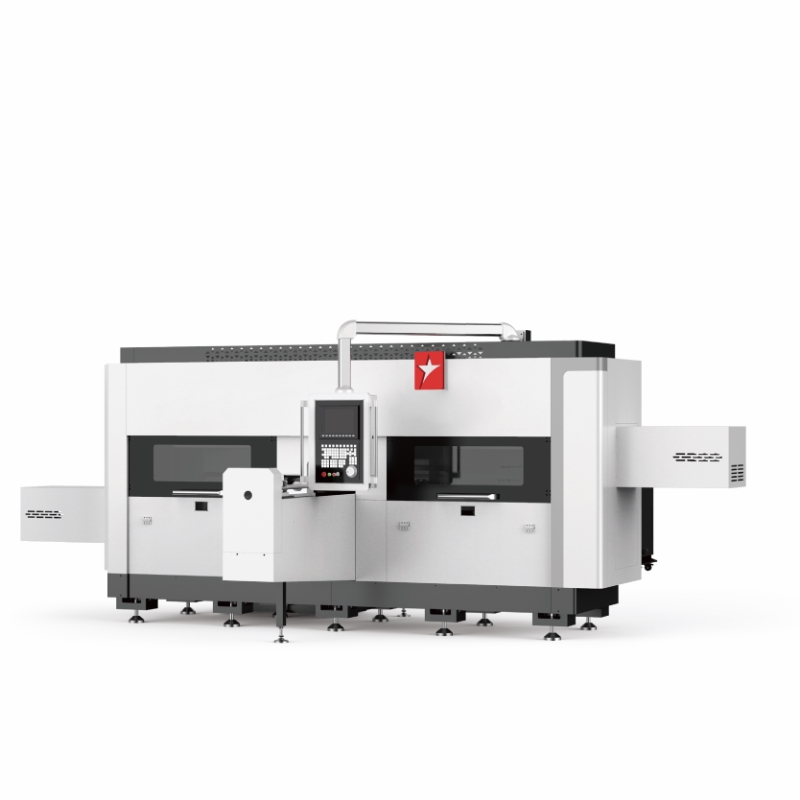

When it comes to precision engineering, horizontal CNC machining centers have become vital in various industries due to their efficiency and accuracy. These advanced machines are designed to handle complex tasks and improve production rates, making them ideal solutions for manufacturers looking to optimize their processes. Globally, businesses are seeking reliable manufacturers that offer not just quality machines but also exceptional service, ensuring they can maintain a competitive edge in their respective markets. Top manufacturers in the field provide a range of horizontal CNC machining centers that cater to diverse applications, from automotive and aerospace to medical device manufacturing. Their technology enhances machining capabilities by incorporating features like high-speed spindles, robust construction, and user-friendly interfaces. In addition, these manufacturers often provide tailored solutions to meet the specific needs of their clients, assisting them in achieving their production goals efficiently. Partnering with reputable horizontal CNC machining center manufacturers is crucial for businesses aiming to enhance their operational efficiency. By investing in high-quality machinery from trusted sources, manufacturers can reduce downtime, improve precision, and ultimately increase their profitability. As the demand for advanced manufacturing solutions continues to grow, aligning with the right partners in this space becomes essential for success in today’s competitive landscape.

Horizontal CNC Machining Centers Application Manufacturers You Can Rely On

| Application Area | Machine Type | Material Compatibility | Control System | Spindle Speed (RPM) |

|---|---|---|---|---|

| Aerospace Parts | Horizontal CNC Mill | Aluminum, Titanium | Fanuc | 12000 |

| Automotive Components | Horizontal CNC Lathe | Steel, Plastics | Siemens | 8000 |

| Medical Devices | Horizontal CNC Machining Center | Stainless Steel, Titanium | Mitsubishi | 10000 |

| Industrial Equipment | Horizontal CNC Cell | Cast Iron, Aluminum | Heidenhain | 6000 |

| Consumer Electronics | Horizontal CNC Router | Plastics, Composites | Fagor | 15000 |

Related Products