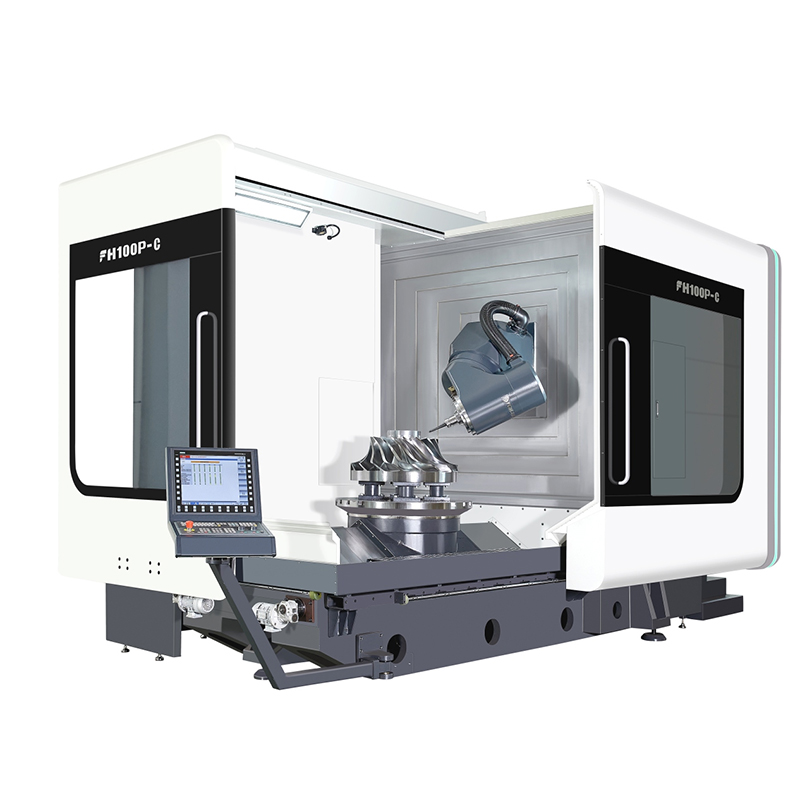

Heavy Duty Vertical Lathe Manufacturer in China - Quality & Precision

As a professional in the machining industry, I understand how crucial it is to find reliable equipment that meets your heavy-duty needs. Our Heavy Duty Vertical Lathe, manufactured in China, is designed for precision and durability, perfect for large-scale applications. With a robust construction, it handles even the toughest materials effortlessly, ensuring you get the best performance every time. I’ve seen firsthand how this lathe enhances productivity and accuracy, making it an ideal choice for any machining workshop. Plus, being from a trusted Chinese manufacturer, you can rest assured of high-quality standards that come with every machine. If you’re on the search for dependable machinery that can withstand heavy workloads without compromising on quality, our Heavy Duty Vertical Lathe might just be what you need. Let’s elevate your machining capabilities together!

Heavy Duty Vertical Lathe Application Pioneers in the Field

In the realm of precision engineering, heavy-duty vertical lathes have emerged as indispensable tools for manufacturers seeking efficiency and accuracy. These robust machines cater to a multitude of applications, including the aerospace, automotive, and energy sectors, where the need for reliable and durable components is paramount. As industries evolve, the demand for innovative machining solutions continues to grow, prompting experts to explore cutting-edge advancements in vertical lathe technology. One of the standout features of modern heavy-duty vertical lathes is their ability to handle complex machining tasks with ease. Equipped with advanced CNC controls, these machines allow for improved automation and precision, reducing manual intervention and minimizing errors. The versatility of heavy-duty vertical lathes enables them to process components of varying sizes and materials, making them a vital asset in both small-scale operations and large industrial setups. This adaptability not only enhances productivity but also helps manufacturers meet customized demands with shorter lead times. As global procurement continues to embrace technological advancements, investing in high-quality heavy-duty vertical lathes becomes crucial for industry leaders aiming to maintain a competitive edge. By leveraging these innovative machines, manufacturers can elevate their production capabilities and drive economic growth, paving the way for a more efficient and sustainable future in engineering. With an unwavering commitment to quality and performance, pioneers in this field are setting new standards that inspire confidence among buyers worldwide.

Heavy Duty Vertical Lathe Application Pioneers in the Field

| Application Area | Material Used | Precision Level | Production Capacity | User Industry |

|---|---|---|---|---|

| Aerospace Components | Titanium Alloy | ±0.01 mm | 100 units/day | Aerospace |

| Heavy Machinery Parts | Cast Iron | ±0.02 mm | 200 units/day | Manufacturing |

| Energy Sector Components | Stainless Steel | ±0.05 mm | 150 units/day | Energy |

| Railway Equipment | Carbon Steel | ±0.01 mm | 250 units/day | Transportation |

| Specialized Marine Parts | Alloy Steel | ±0.03 mm | 80 units/day | Marine |

Related Products