Gantry Boring Machine Manufacturer in China: Quality and Precision Solutions

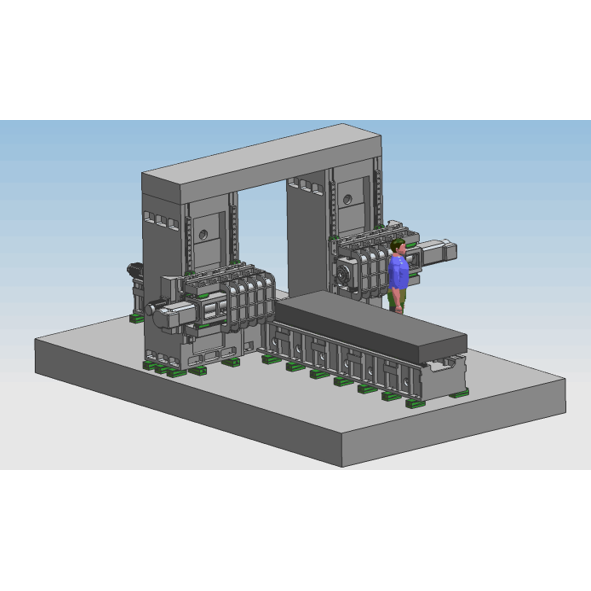

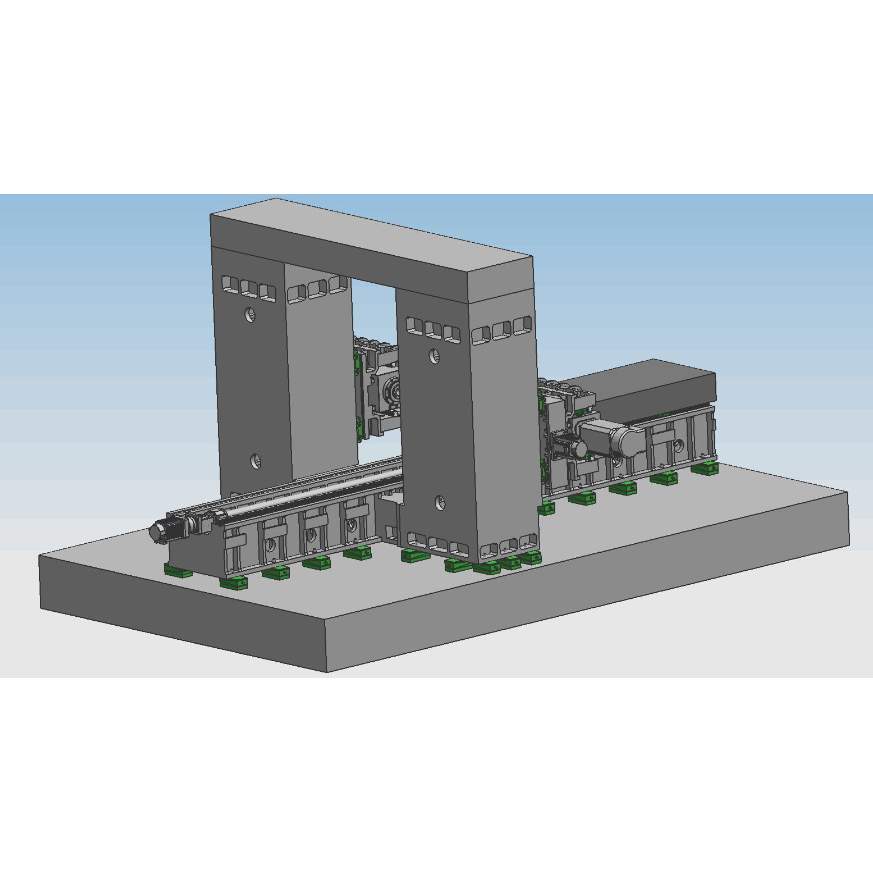

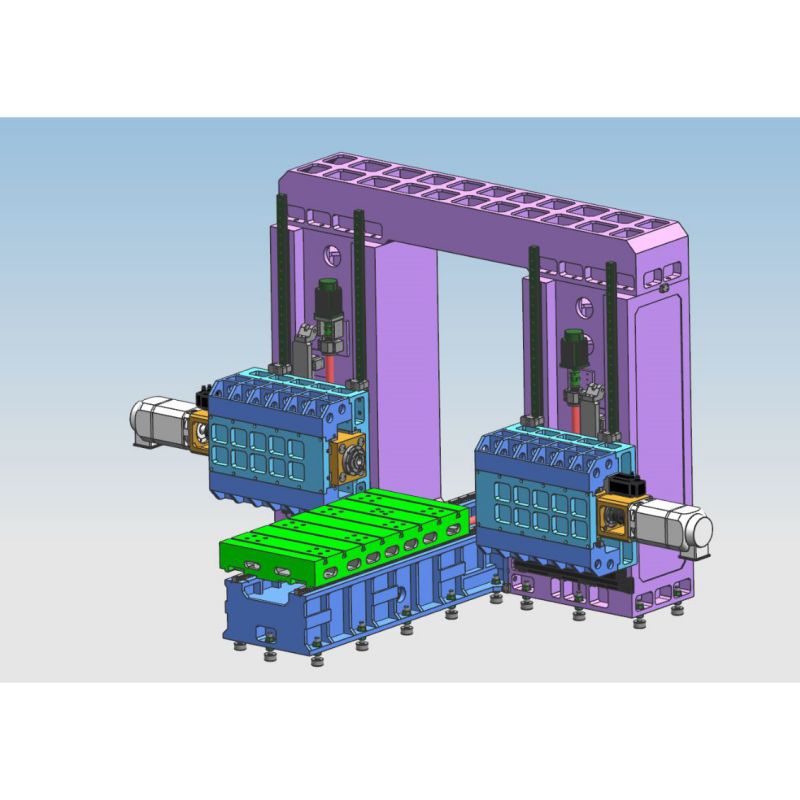

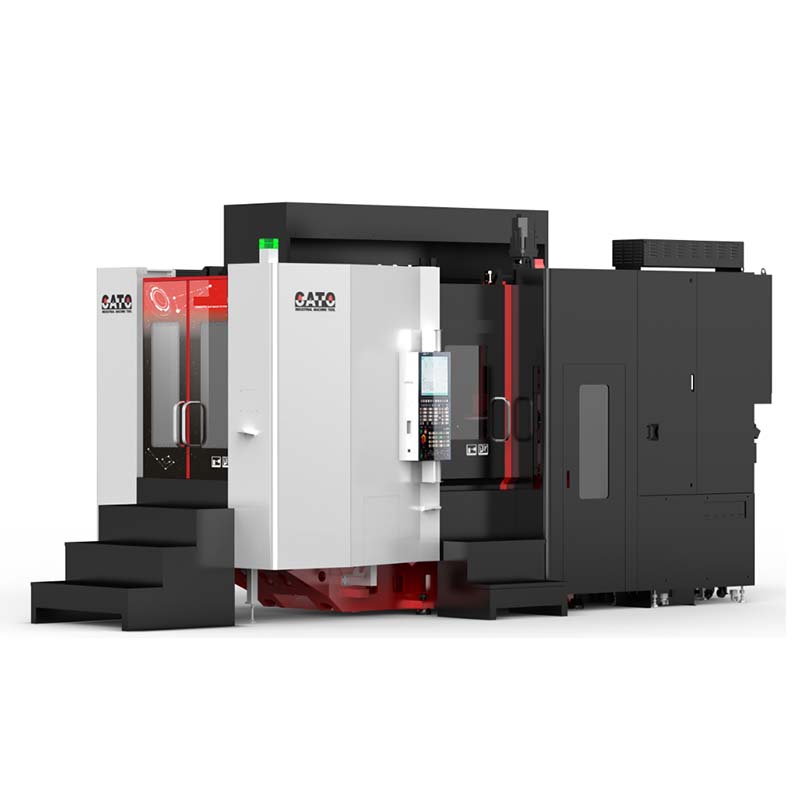

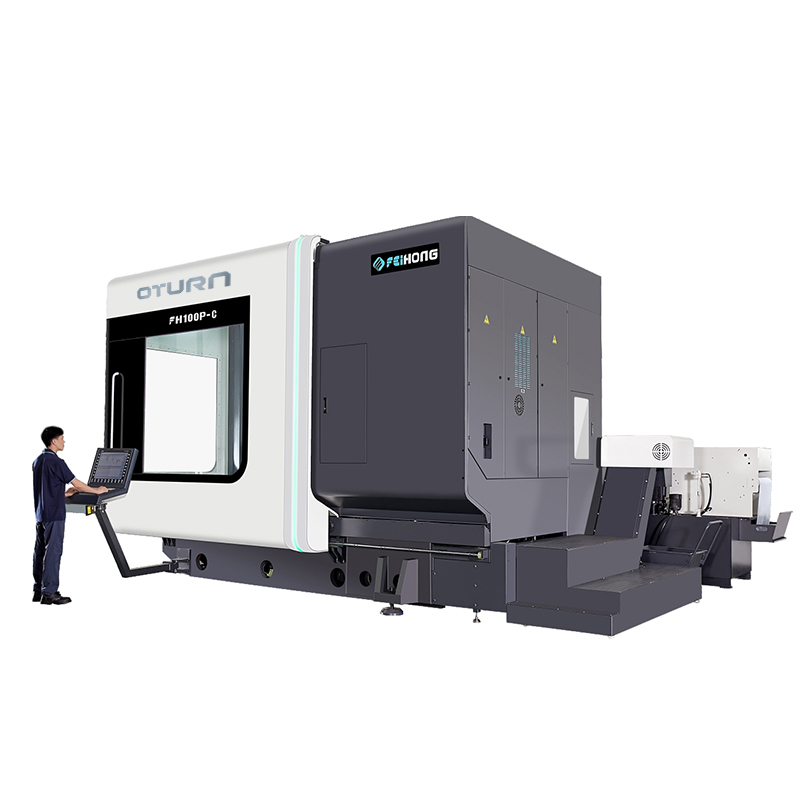

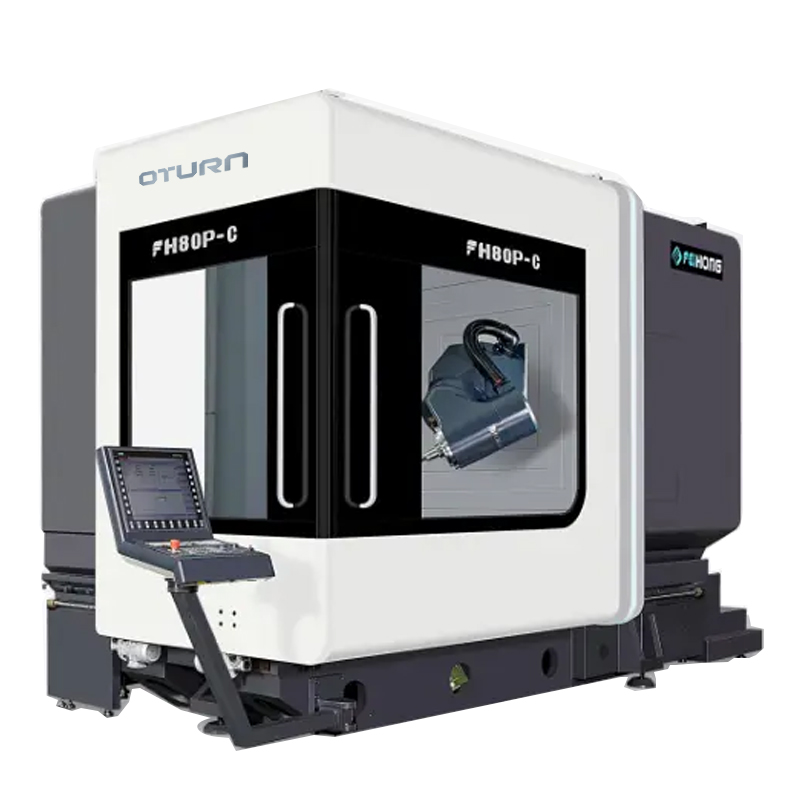

When it comes to precision and efficiency in machining, I can’t help but recommend our Gantry Boring Machine, proudly manufactured in China. This advanced equipment is designed to meet the high demands of your industrial projects, providing unmatched accuracy in large-scale boring operations. As a buyer, I understand you need reliability and performance, and our machines are built to last. Featuring robust construction and cutting-edge technology, this gantry boring machine can handle various materials and deliver consistent results. I’ve seen firsthand how our customers have streamlined their processes and increased productivity with this tool. It’s not just about the machine; it’s about what it can do for your business. Let our expertise in manufacturing empower your operations and help you achieve your goals. You won't just invest in a machine; you’ll invest in a solution that drives your success.

Gantry Boring Machine Manufacturer More Than a Supplier - A Partner

In today's competitive manufacturing landscape, choosing the right gantry boring machine manufacturer goes beyond simply sourcing high-quality machinery. It's about forming a strategic partnership that empowers your business, enhances operational efficiency, and drives growth. A reliable manufacturer understands that their role extends into your production process, offering not just products, but solutions tailored to meet your specific needs. By working closely with clients, a dedicated gantry boring machine manufacturer can provide invaluable insights into the latest technological advancements and industry trends. This collaboration helps procurement teams make informed decisions, ensuring that they invest in machinery that increases productivity and minimizes downtime. Furthermore, the right partner will offer comprehensive support, from installation to maintenance, ensuring that your operations run smoothly and effectively. Investing in a partnership with a skilled gantry boring machine manufacturer can lead to significant advantages. This collaborative approach not only enhances the quality of the machines you procure but also fosters innovation and adaptability in your production processes. As industries evolve, a strong partnership can position your business to respond to changing market demands swiftly and efficiently. Embrace the opportunity to work with a manufacturer that prioritizes your success and is committed to being more than just a supplier; be prepared to engage in a long-term partnership that drives mutual growth.

Gantry Boring Machine Manufacturer More Than a Supplier - A Partner

| Dimension | Description | Benefits | Applications | Materials |

|---|---|---|---|---|

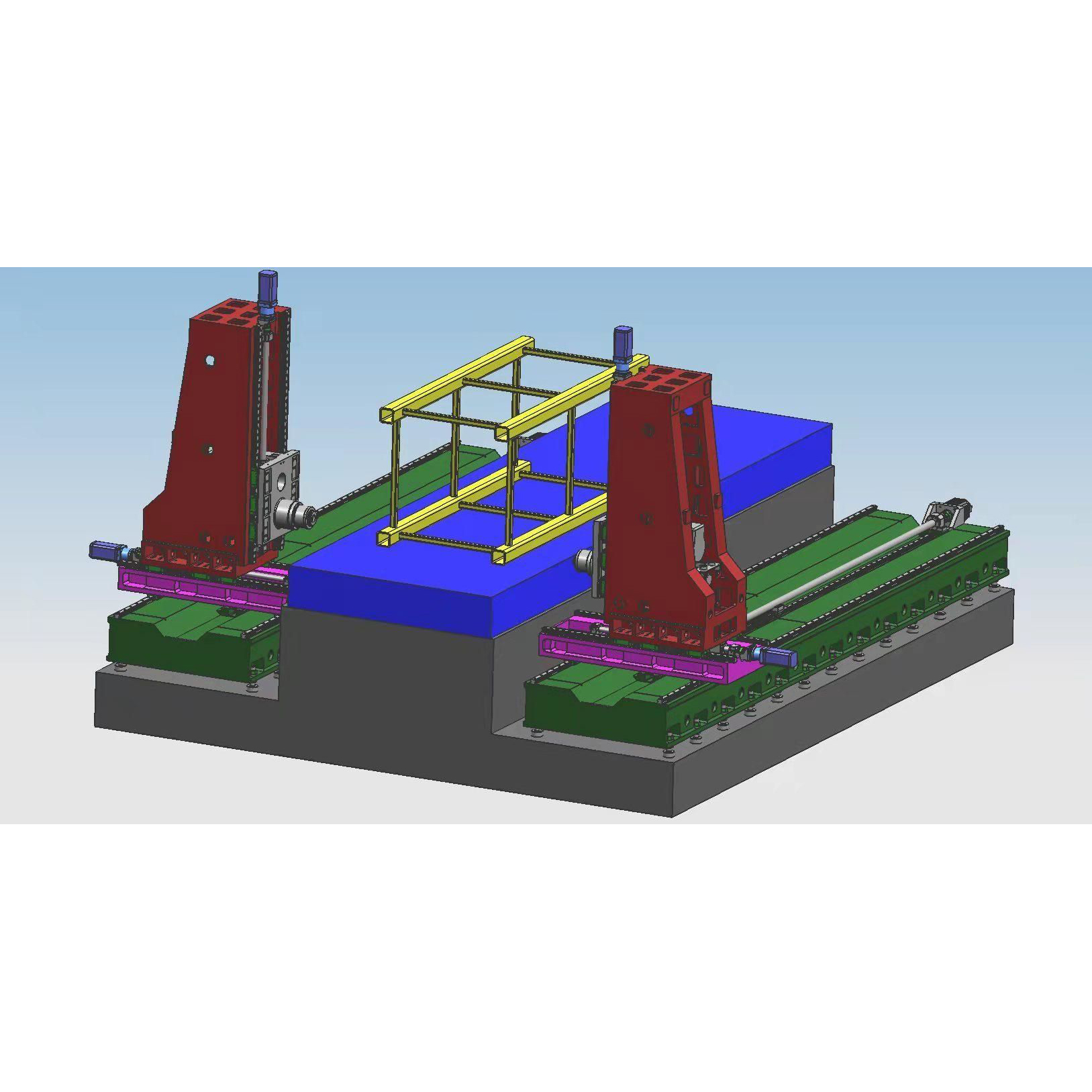

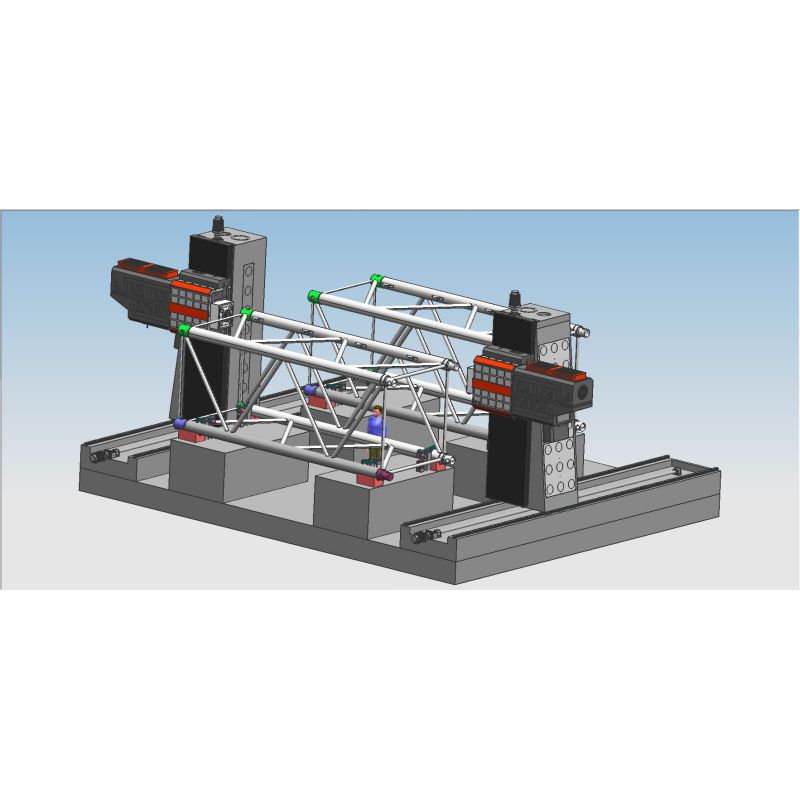

| Travel Range | Allows for large-scale machining projects | Increased efficiency and precision | Aerospace, Marine, and Energy industries | Aluminum, Steel, Titanium |

| Spindle Speed | High-speed operations for rapid machining | Reduces cycle times significantly | Automotive components, Mold making | Composite materials, Plastics |

| Control System | Advanced CNC for precise control | Enhanced machine monitoring | Prototype development, Custom fabrication | Various alloys, Soft metals |

| Size & Weight Capacity | Can handle large and heavy workpieces | Improves durability and stability during operations | Construction, Heavy machinery | Tool steel, Cast iron |

Related Products