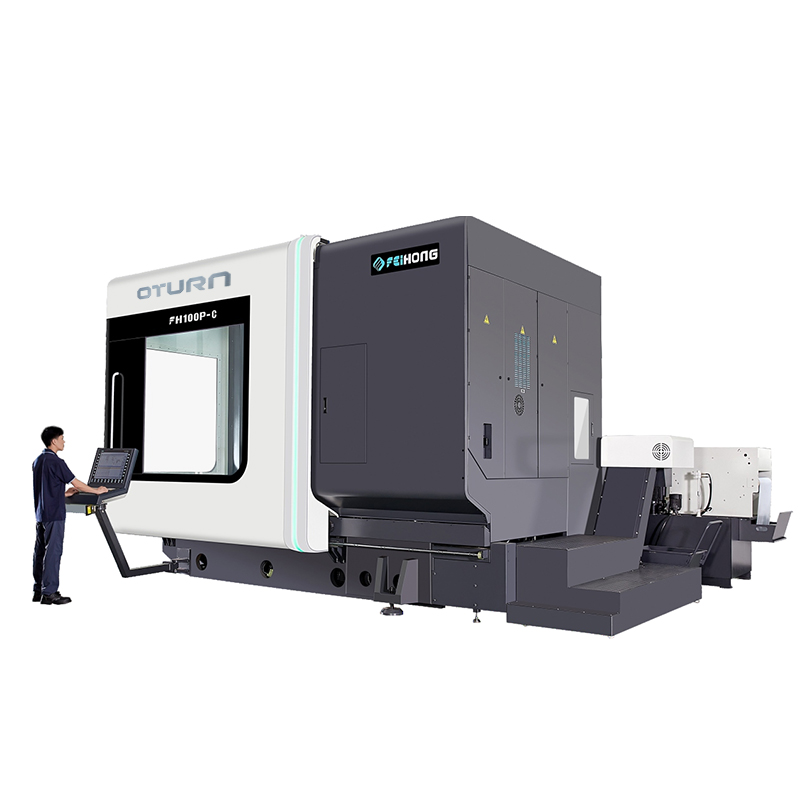

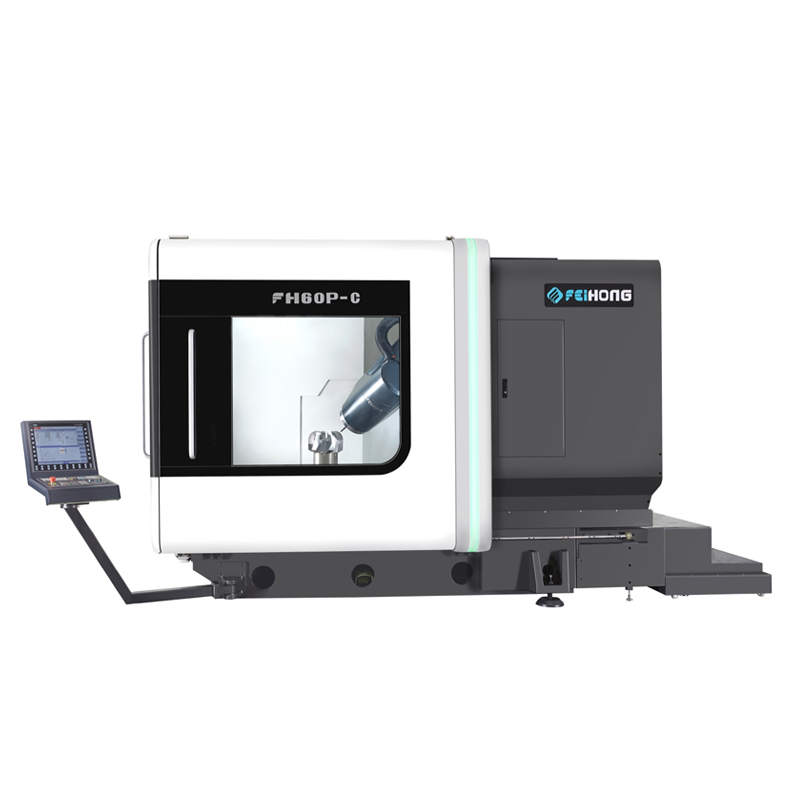

Top China Manufacturer of Five Axis Machining Centers for Precision Engineering

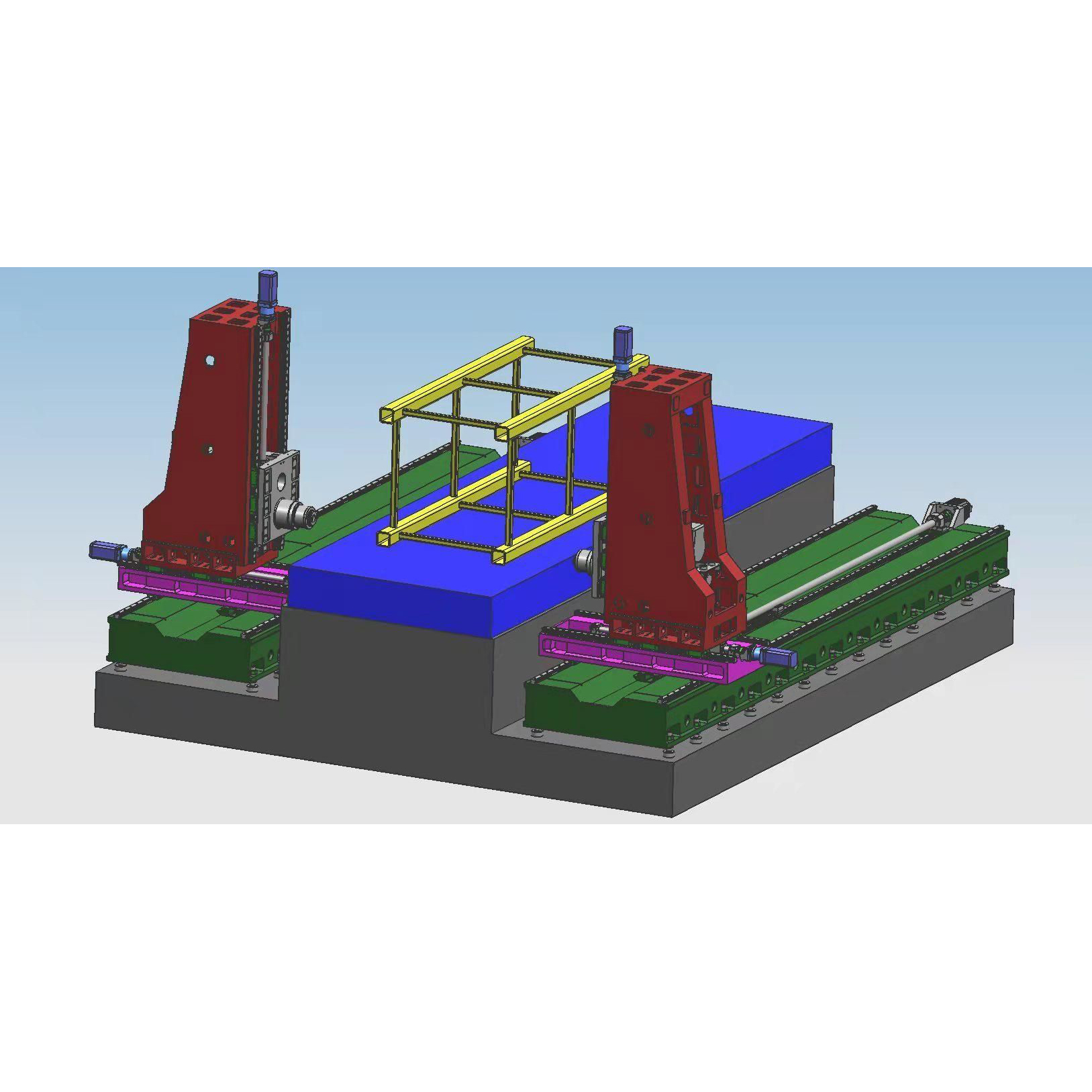

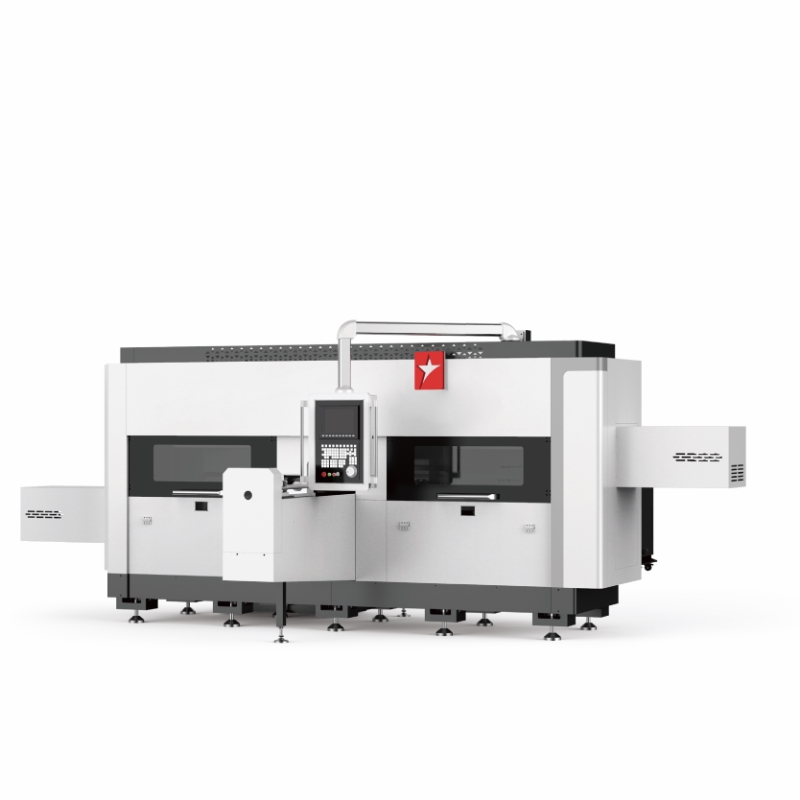

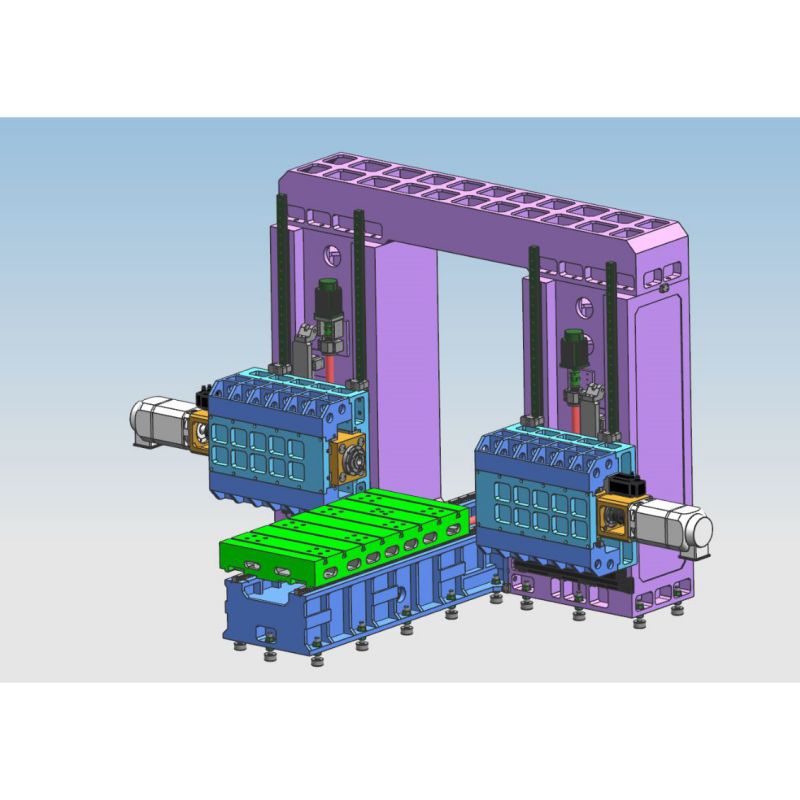

When I first started exploring the world of precision machining, the Five Axis Machining Center quickly became a game changer for my projects. This advanced equipment allows for intricate designs and complex parts that traditional machines just can't handle. Being a manufacturer based in China, I take great pride in our ability to produce high-quality machining centers tailored for various industries. Our Five Axis Machining Center stands out due to its robust construction and user-friendly interface, making it ideal for both seasoned professionals and newcomers. I've seen firsthand how it reduces production time and improves accuracy, enabling my clients to meet their demanding specifications effectively. Whether you're looking to enhance your manufacturing capabilities or streamline your operations, our Five Axis Machining Center is designed to elevate your productivity. Choose us as your trusted partner, and let's take your manufacturing to the next level together.

Five Axis Machining Center Ahead of the Curve Guarantees Peak Performance

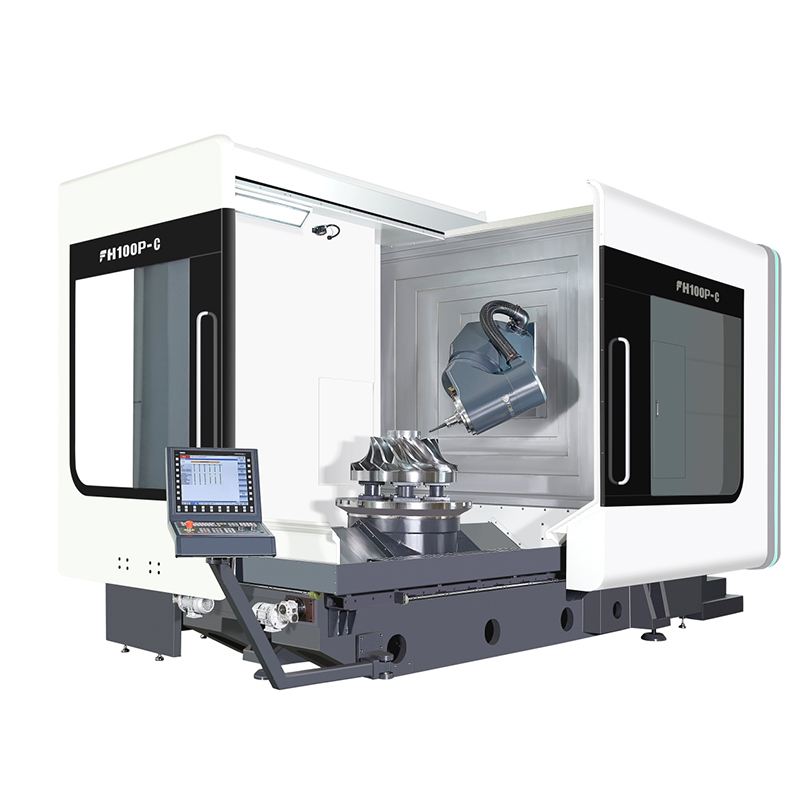

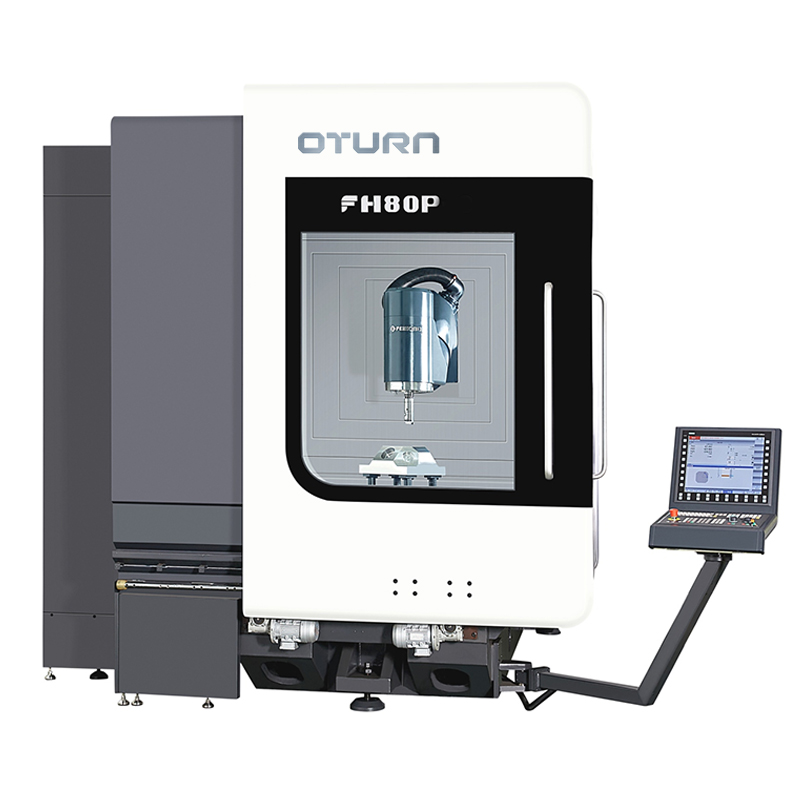

In today’s highly competitive manufacturing landscape, investing in advanced technology is crucial for achieving peak performance. The Five Axis Machining Center stands out as a cornerstone for precision machining, enabling manufacturers to produce complex geometries with unmatched accuracy and efficiency. This innovative machinery accommodates intricate designs that traditional machining centers struggle to handle, reducing the need for multiple setups and minimizing production time. Moreover, the versatility of Five Axis Machining Centers opens doors to various industries, from aerospace to medical devices. With the capability to machine various materials, including exotic alloys and composites, these centers provide a significant advantage for businesses aiming to enhance their manufacturing processes. The integration of intelligent software solutions further boosts productivity by optimizing tool paths and reducing manual intervention, ensuring that companies can maintain high output while minimizing operational costs. Investing in a Five Axis Machining Center not only positions your operations ahead of the curve but also sets the stage for innovation and growth. As global demands continue to evolve, embracing such cutting-edge solutions will empower manufacturers to remain competitive, meet customer expectations, and secure their place in the future of manufacturing.

Five Axis Machining Center Ahead of the Curve Guarantees Peak Performance

| Feature | Description | Advantage | Application |

|---|---|---|---|

| High Precision | Achieves tolerances of ±0.005 mm | Reduces waste, improving efficiency | Aerospace, Automotive |

| Multi-Axis Capability | Simultaneously controls five axes | Complex geometries can be machined | Medical Devices, Molds |

| Rigid Construction | Sturdy frame minimizes vibrations | Enhanced stability during machining | Precision Engineering, Aerospace |

| User-Friendly Interface | Intuitive control system for easy operation | Reduces training time for operators | General Manufacturing |

| Advanced Tooling | Compatible with a range of tools | Flexible machining options | Custom Parts, Prototyping |

Related Products