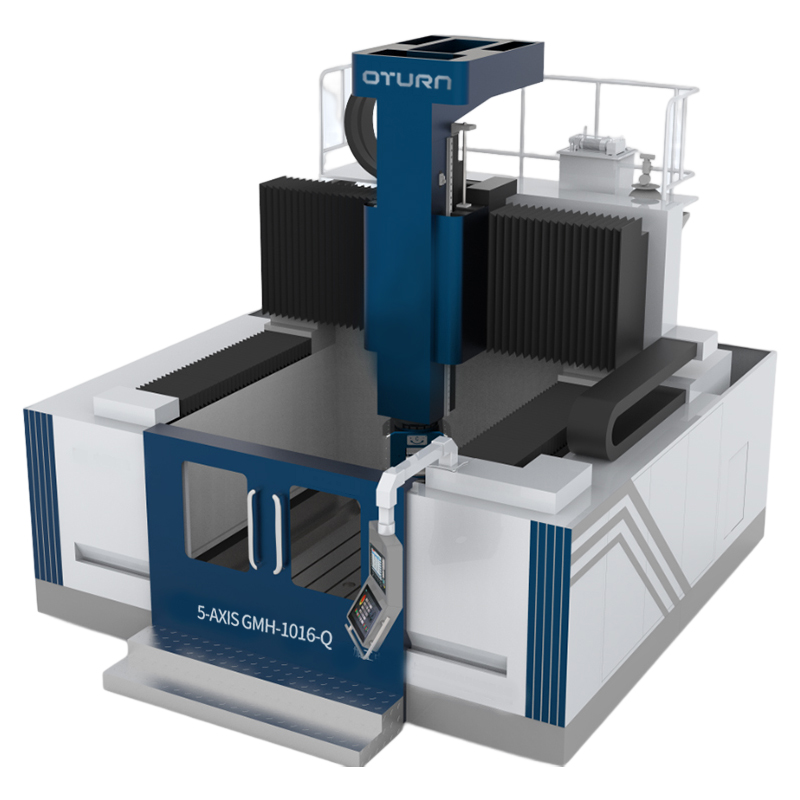

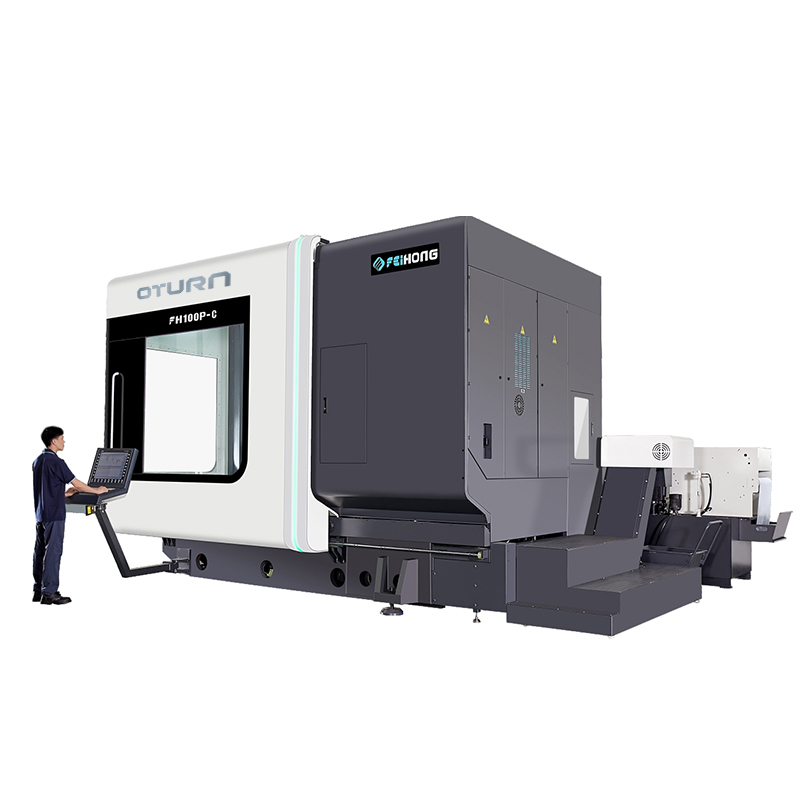

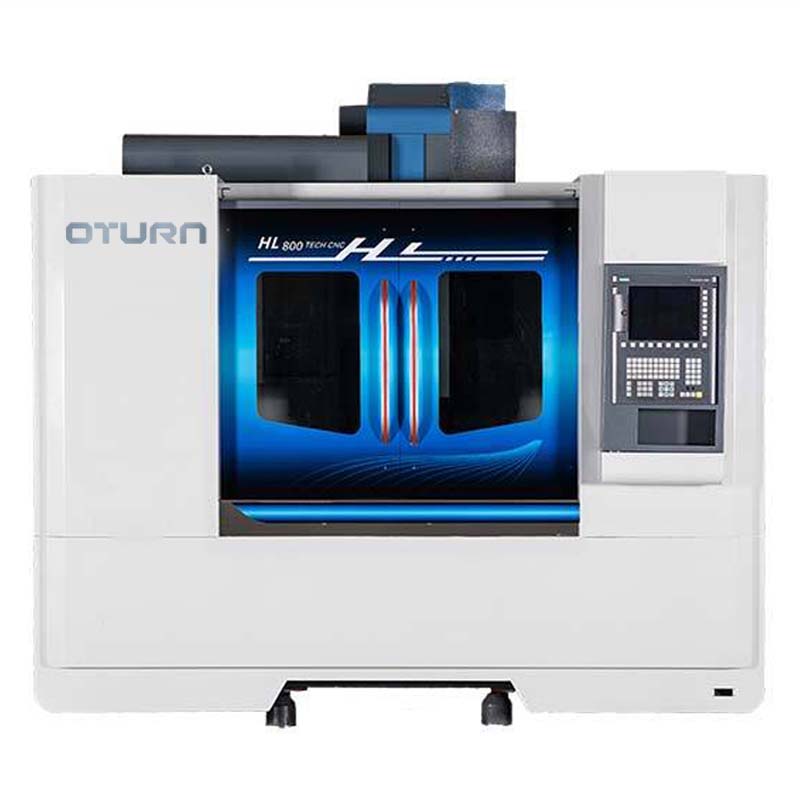

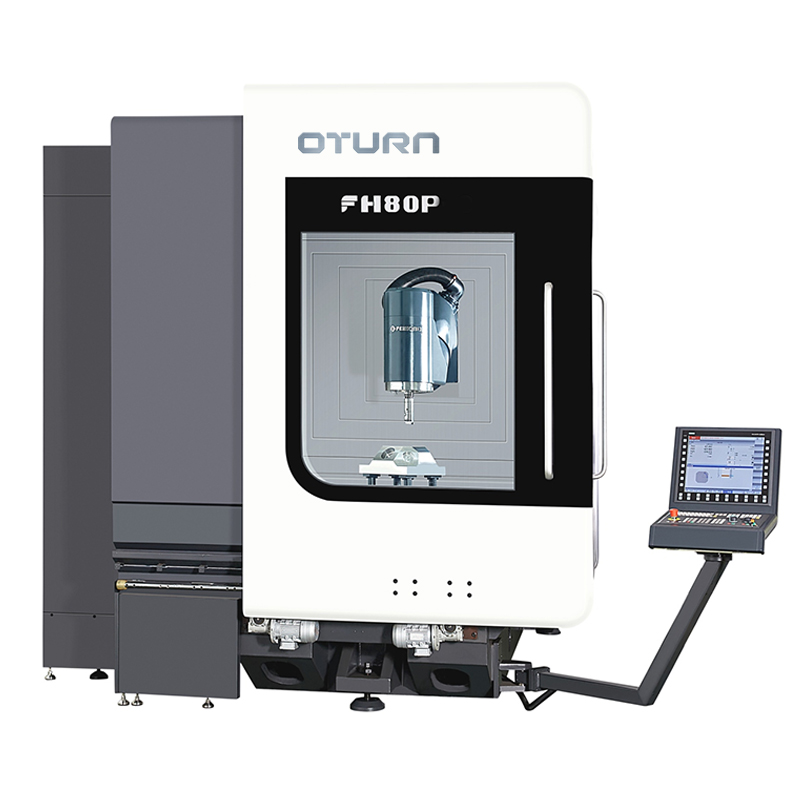

CNC Turning Centre Manufacturer in China: Precision Engineering Solutions

When it comes to precision machining, the Cnc Turning Centre we offer stands out for its exceptional reliability and performance. As a manufacturer based in China, we understand the needs of B2B purchasers like you who demand quality and efficiency. Our Cnc Turning Centre is designed to handle a variety of materials, ensuring you can meet your production requirements with ease. With advanced technology and robust construction, this machine provides flawless precision for every job, minimizing downtime and maximizing your output. I know how important it is for manufacturers to have the right tools at their disposal. That’s why we prioritize quality in every unit we produce, giving you peace of mind in your investment. Whether you’re looking to scale up production or improve existing processes, our Cnc Turning Centre is the ideal solution for your manufacturing needs. Let’s elevate your operations together!

Cnc Turning Centre Stands Out in 2025

In the rapidly evolving landscape of precision machining, the CNC turning center is establishing itself as an essential asset for manufacturers aiming for enhanced productivity and accuracy. As we step into 2025, advancements in technology are significantly transforming the capabilities of CNC turning centers, making them indispensable tools for global procurement professionals seeking to optimize their manufacturing processes. With features like automated tool changes, improved software functionality, and enhanced spindle speeds, these machines are now more efficient than ever, allowing for the production of complex components in shorter timeframes. The rise of smart manufacturing further elevates the significance of CNC turning centers. Integrating IoT technologies enables real-time data monitoring and predictive maintenance, reducing downtime and ensuring consistent output quality. This adaptability is particularly appealing to procurement managers looking to streamline their supply chains and reduce operational costs. As industries continue to face challenges in global logistics and sustained supply chain efficiencies, the reliability and precision offered by advanced CNC turning centers can provide the competitive edge needed in today’s market. For businesses aiming to meet the increasing demand for high-quality, precision-engineered components, investing in a state-of-the-art CNC turning center is not merely an option but a strategic imperative. As we look forward to the future of machining, the continued evolution of these centers promises to deliver unmatched capabilities that can respond to the complexities of modern manufacturing, ultimately benefiting entire supply chains and driving innovation across various sectors.

Cnc Turning Centre Stands Out in 2025

| Feature | Specification | Benefits |

|---|---|---|

| High Precision | ±0.01 mm tolerance | Ensures high quality and consistent manufacturing results. |

| Speed | 2000 RPM spindle speed | Reduces cycle time and enhances productivity. |

| Automation | Fully automated loading and unloading | Minimizes human error and increases efficiency. |

| Material Compatibility | Aluminum, brass, steel, plastic | Versatile for various applications and industries. |

| User Interface | Touchscreen control panel | Easy operation and monitoring of the machining process. |

| Energy Efficiency | Low power consumption | Reduces operating costs and environmental impact. |

Related Products