CNC Machining: Top China Manufacturer for Precision Parts and Solutions

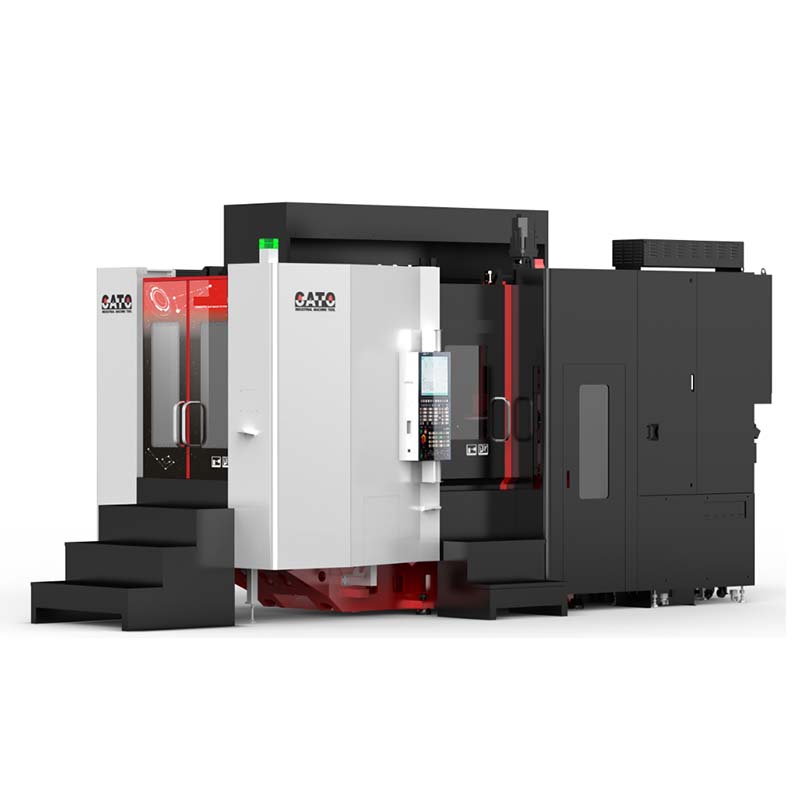

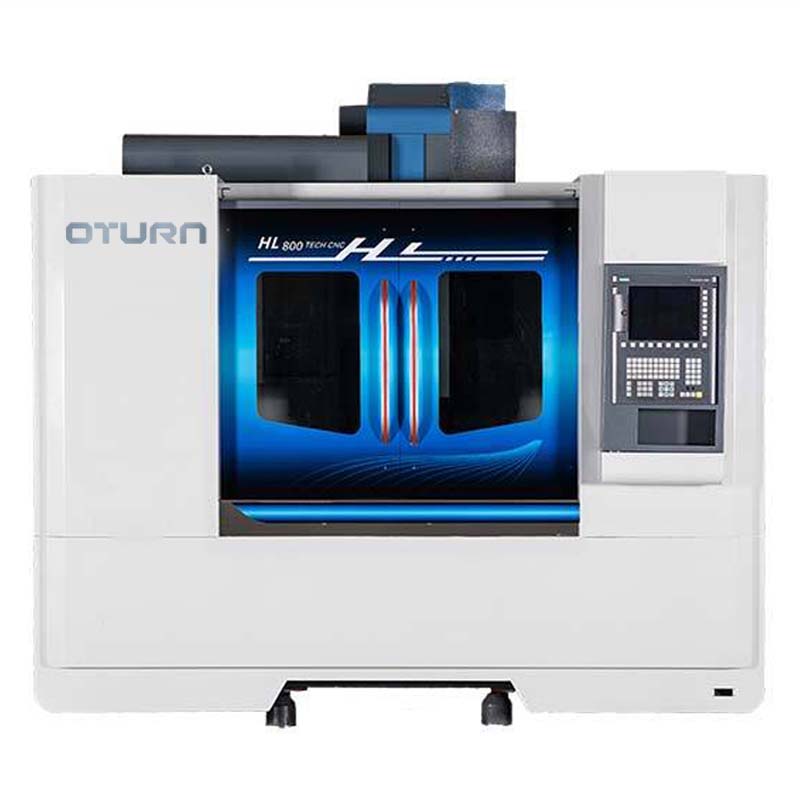

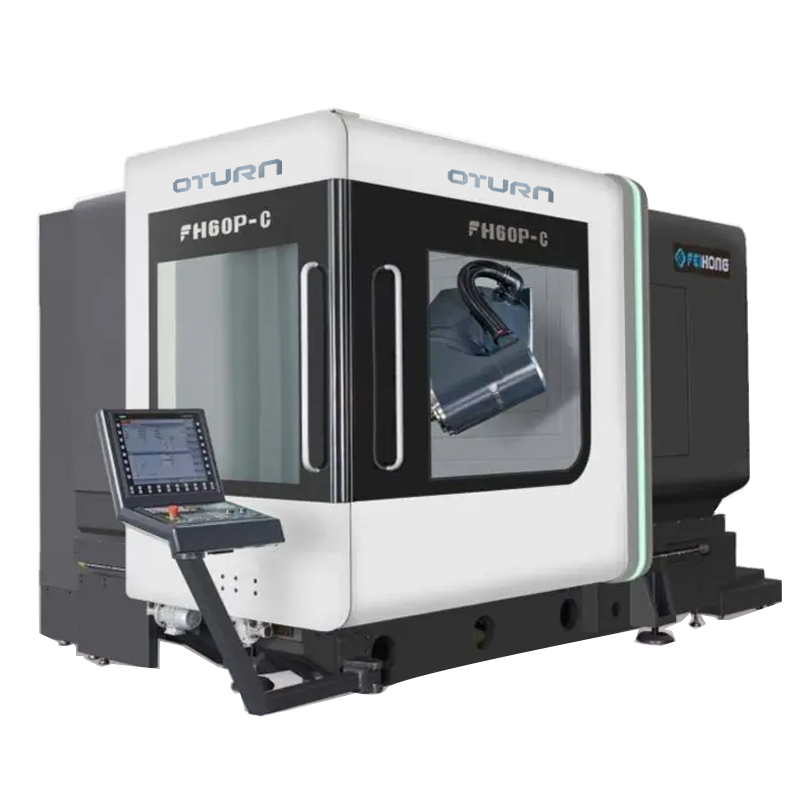

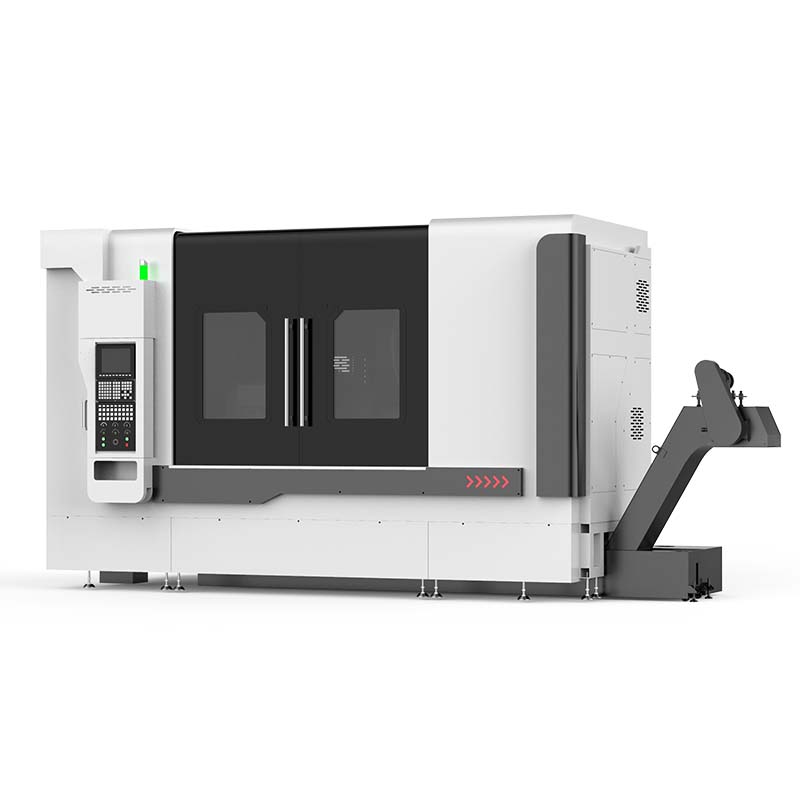

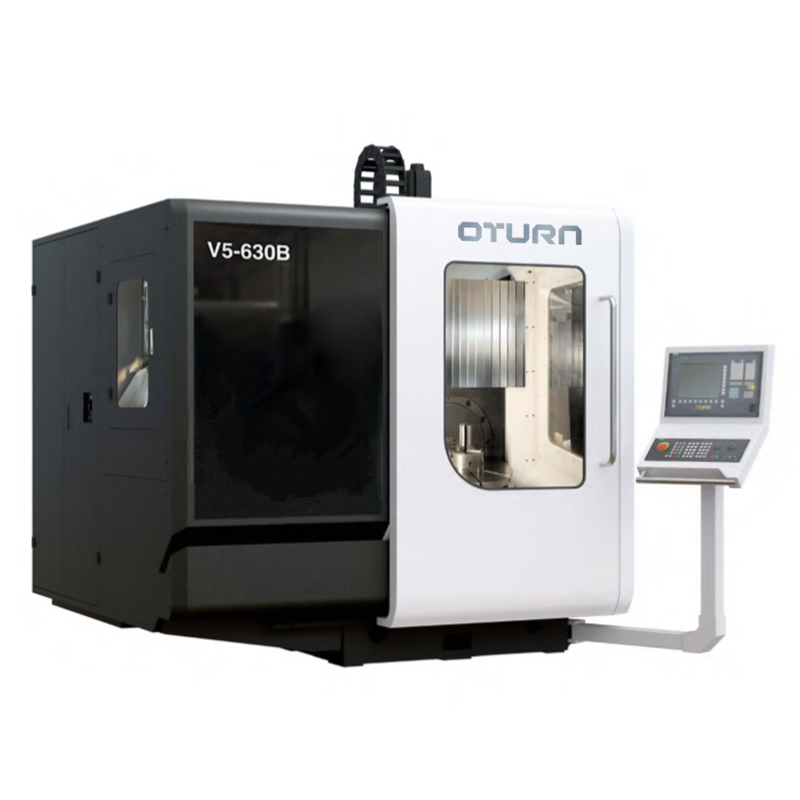

As a dedicated expert in CNC Machining, I understand the importance of precision and quality in part manufacturing. Our services cater to businesses seeking reliable solutions from a trusted manufacturer in China. Whether you need prototypes or large production runs, I can help you achieve your specific requirements with our advanced technologies and skilled workforce. We pride ourselves on delivering tailored solutions that meet your unique project needs. I’ve seen firsthand how our competitive pricing and fast turnaround times can positively impact your bottom line. With rigorous quality control processes in place, each component is crafted to ensure that it meets industry standards. Partnering with us means you’ll benefit from not just our machinery but our commitment to exceptional service. Let’s work together to bring your designs to life with efficiency and accuracy, making your business stand out in the competitive market. Reach out today to explore how we can support your machining projects!

CNC Machining Application Where Innovation Meets 2025

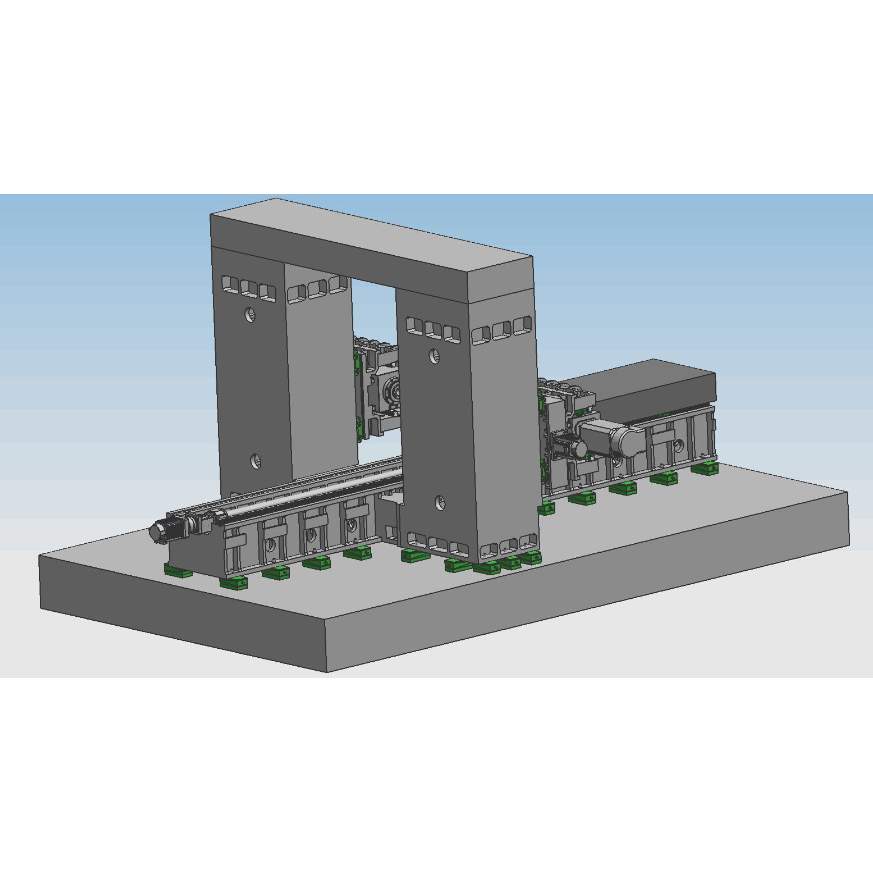

In the rapidly evolving landscape of manufacturing, CNC machining stands at the forefront of innovation, offering unparalleled precision and efficiency for various applications. As we move towards 2025, the integration of advanced technologies such as artificial intelligence, automation, and IoT is transforming CNC machining processes, making them more agile and responsive to market demands. Companies worldwide are increasingly turning to CNC solutions for their versatility—ranging from aerospace and automotive to medical devices and consumer goods—allowing for the creation of complex geometries that traditional machining methods cannot achieve. One of the most exciting developments in CNC machining is the rise of smart machining centers equipped with adaptive software systems. These technologies enable real-time monitoring and adjustments, reducing downtime and improving output quality. Global procurement professionals are particularly interested in sourcing providers who leverage such advancements. Sustainable practices are also becoming a priority, as manufacturers seek to minimize waste and energy consumption while maintaining high production standards. This synergy of innovation and sustainability ensures that CNC machining not only meets immediate production needs but also aligns with long-term environmental goals. As we anticipate the future of CNC machining, it's clear that staying ahead means embracing technological innovations that empower businesses to thrive in a competitive market. Buyers seeking reliable partners in this space should focus on suppliers who are committed to continuous improvement and are equipped to adapt to evolving industry trends. By investing in cutting-edge machining solutions now, companies can position themselves as leaders in their respective fields by 2025 and beyond.

CNC Machining Application Where Innovation Meets 2025

| Application Area | Material Used | Process Type | Year of Implementation | Innovation Level |

|---|---|---|---|---|

| Aerospace Components | Titanium Alloy | Milling | 2025 | High |

| Medical Devices | Stainless Steel | Turning | 2025 | Medium |

| Automotive Parts | Aluminum | Grinding | 2025 | High |

| Electronics Housing | Plastic Composites | Laser Cutting | 2025 | Low |

| Robotics | Carbon Fiber | 3D Printing | 2025 | High |

Related Products