CNC Lathe Machining Services by Top Manufacturer in China

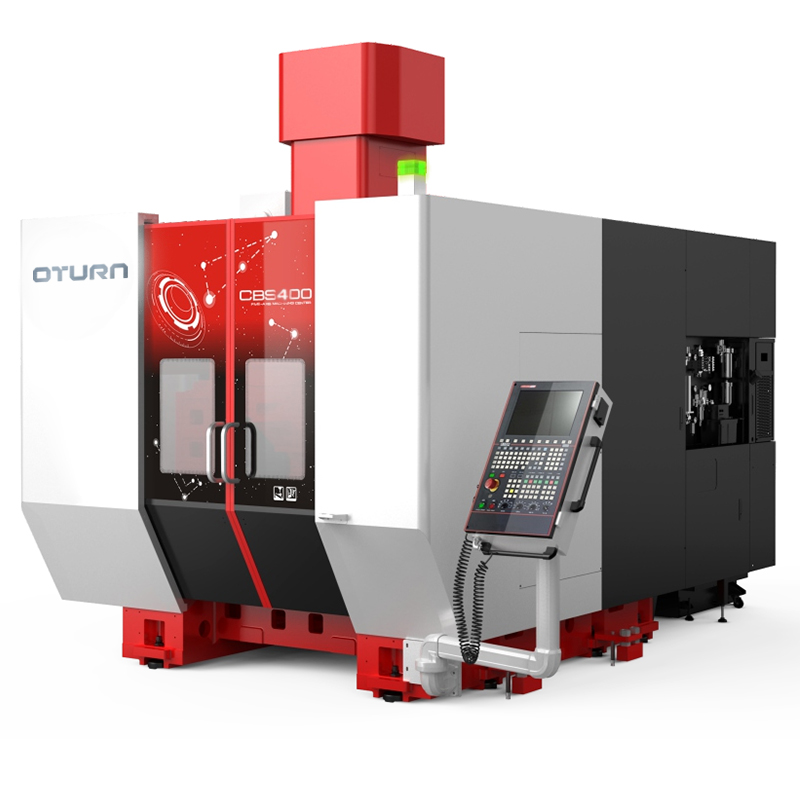

As a dedicated expert in CNC lathe machining, I understand the importance of precision and quality for your projects. Our CNC lathe machining services, based in China, are tailored to meet the diverse needs of B2B purchasers like you. Our advanced manufacturing techniques ensure that every part we produce adheres to your specifications, leading to enhanced productivity and lower operational costs. We pride ourselves on our ability to work closely with clients, providing custom solutions that align with your unique requirements. Whether you need components for automotive, aerospace, or machinery, our expert team is ready to assist. Quality control is paramount in our processes, ensuring that you receive only top-tier products. Partnering with us means gaining access to a reliable manufacturer that values your business as much as you do. Let’s work together to take your projects to the next level with our superior CNC lathe machining capabilities.

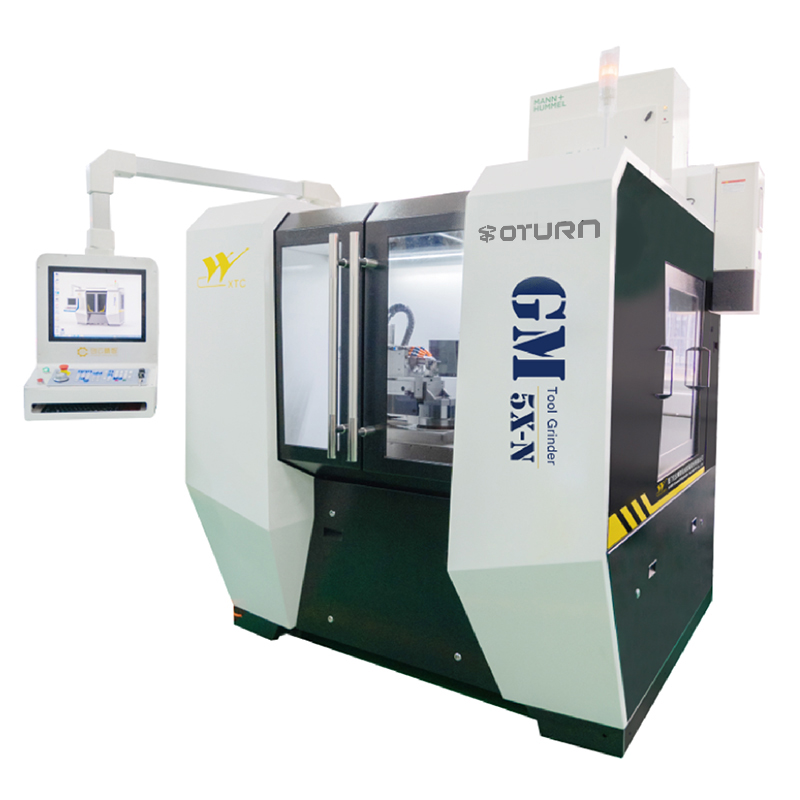

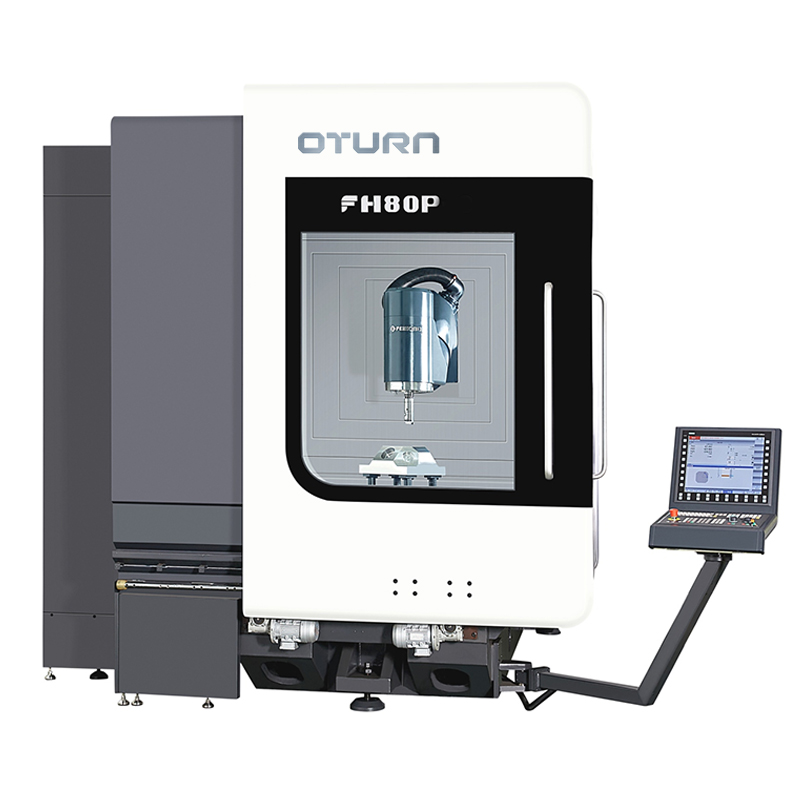

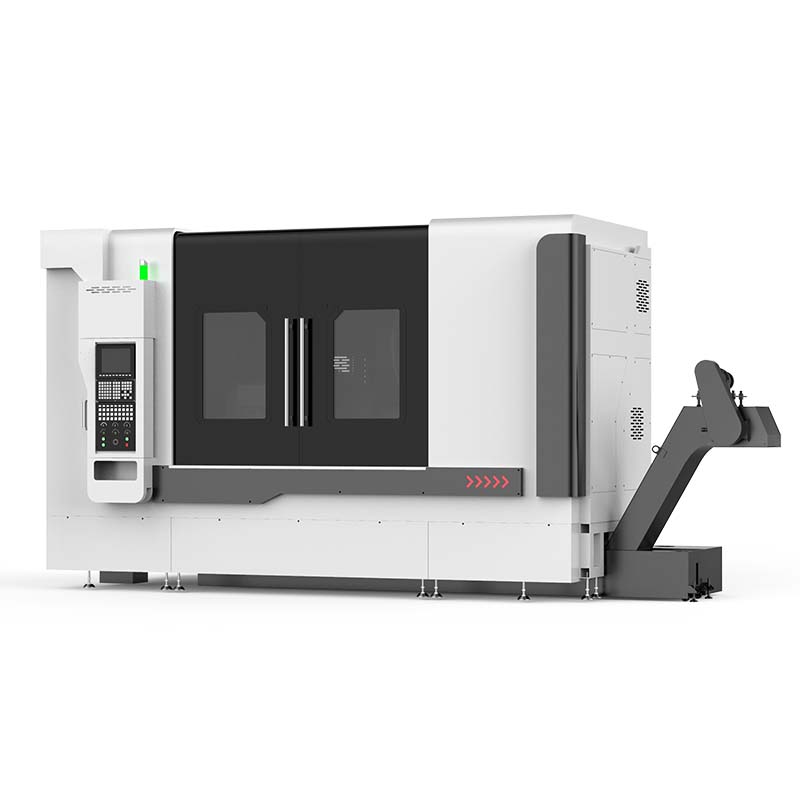

CNC Lathe Machining Products Now Trending

CNC lathe machining products are increasingly becoming the focal point for global buyers seeking precision and efficiency in manufacturing. As industries evolve, the demand for high-quality components has surged, and CNC lathes are at the forefront of this revolution. By utilizing advanced technology, these machines offer unparalleled accuracy, rapid production times, and the ability to handle complex geometries. This has made them a preferred choice for sectors ranging from automotive to aerospace, where precision engineering is crucial. In recent years, the trend towards automation and smart manufacturing has further propelled the adoption of CNC lathe machining. The integration of robotics and IoT solutions enhances productivity and allows for real-time monitoring of operations. As a result, businesses are not just investing in machinery but are also embracing comprehensive solutions that streamline their manufacturing processes. Buyers are increasingly looking for suppliers who can provide not only high-quality CNC components but also added value through technical support and customized solutions tailored to their specific needs. As the global market becomes more interconnected, the sourcing of CNC lathe products from reliable manufacturers is key. Choosing partners who adhere to rigorous quality standards and showcase a strong track record in meeting international requirements can significantly reduce risks and enhance supply chain efficiency. With the rise of e-commerce platforms, procurement has also become more accessible, allowing buyers to connect with manufacturers across the globe seamlessly. Engaging suppliers that prioritize innovation and sustainability will be essential for businesses aspiring to thrive in today's competitive landscape.

CNC Lathe Machining Products Now Trending

| Product Type | Material | Applications | Surface Finish | Dimensions (mm) |

|---|---|---|---|---|

| CNC Turned Parts | Aluminum | Automotive, Aerospace | Anodized | 10-50 |

| CNC Milled Components | Stainless Steel | Medical Equipment | Polished | 20-100 |

| Custom CNC Parts | Brass | Electronics, Home Appliances | Natural | 15-75 |

| Precision Machined Parts | Titanium | Aerospace, Defense | Coated | 30-120 |

| CNC Gear Components | Carbon Steel | Industrial Machinery | Heat Treated | 5-50 |

Related Products