Top CNC Horizontal Machine Manufacturers in China for Precision Solutions

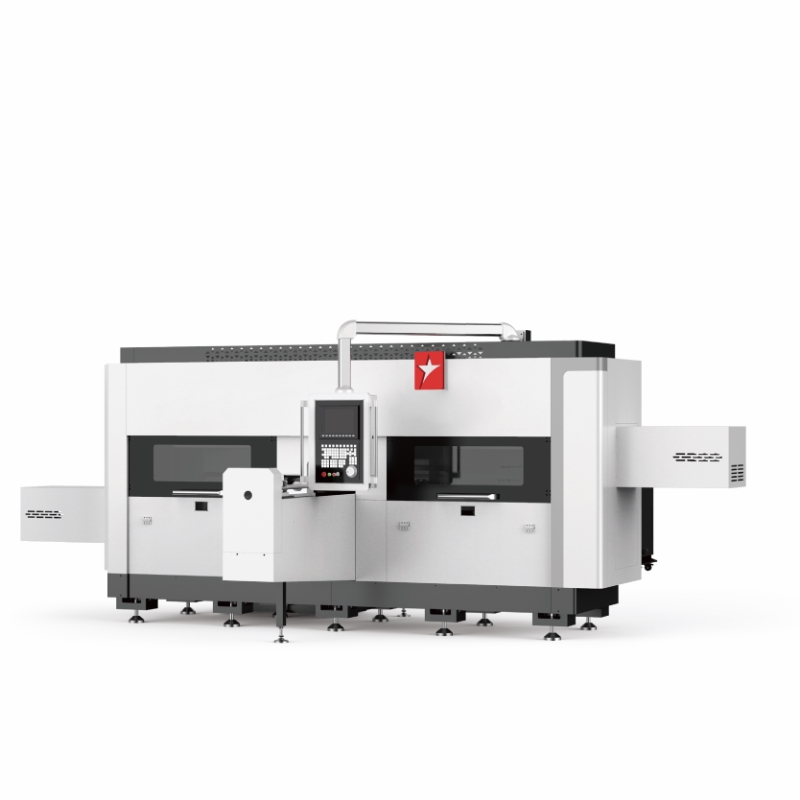

When it comes to precision machining, I stand by our CNC horizontal machine. This equipment is engineered to deliver unmatched accuracy and efficiency, making it the perfect fit for your manufacturing needs. As a reliable Chinese manufacturer, we take pride in our attention to detail and quality control, ensuring that each machine meets the highest standards. Our CNC horizontal machine is designed to handle a variety of materials, maximizing production while minimizing downtime. I know that in the competitive landscape, you need machinery that boosts your output and maintains consistent performance. That’s why our machines are user-friendly and easy to integrate into any workflow. With our commitment to innovation and customer satisfaction, you can trust that choosing our CNC horizontal machine will elevate your business operations. Don’t settle for less when it comes to your manufacturing solutions—partner with a reputable manufacturer who understands your needs.

Cnc Horizontal Machine Application From Concept to Delivery

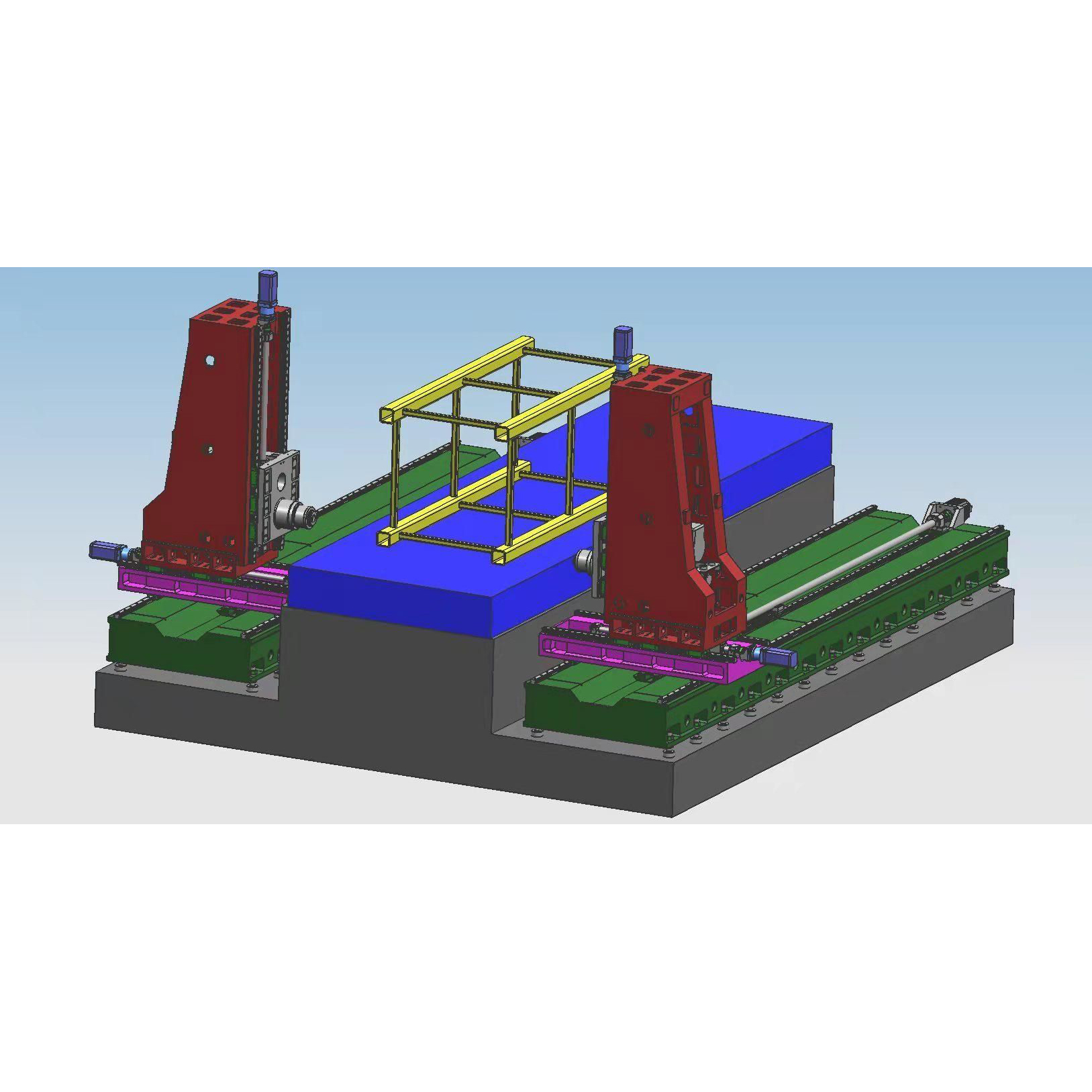

In today's fast-paced manufacturing landscape, the demand for precision and efficiency has led to the widespread adoption of CNC horizontal machining. This advanced technology offers a robust solution for creating complex parts with exceptional accuracy, making it ideal for industries ranging from automotive to aerospace. The journey of CNC horizontal machining begins with a concept, where the unique requirements of each project are carefully analyzed. With a focus on precision engineering, manufacturers can design custom solutions tailored to meet specific client needs. The transition from concept to delivery involves meticulous planning and execution. Engineers use sophisticated software to model and simulate machining processes, ensuring efficiency and reducing potential errors. Once the design is finalized, high-quality materials are selected for production, ensuring durability and performance. As the machining process unfolds, strict quality control measures are implemented at each stage, guaranteeing that every component meets rigorous standards before it reaches the client. Ultimately, the goal is to deliver not just products, but solutions that enhance the productivity of global buyers. By leveraging cutting-edge technology and dedicated expertise, manufacturers can provide timely delivery of high-quality components that empower businesses to succeed in competitive markets. As companies continue to seek reliable partners in their supply chains, the commitment to excellence in CNC horizontal machining stands out as a key differentiator.

| Application Area | Material Type | Machine Model | Production Volume | Delivery Time (Weeks) |

|---|---|---|---|---|

| Automotive Parts | Aluminum Alloy | HAAS EC-400 | 500 units/month | 6 |

| Aerospace Components | Titanium Alloy | Makino A51 | 200 units/month | 8 |

| Medical Devices | Stainless Steel | DMG MORI NMV 5000 DCG | 300 units/month | 5 |

| Industrial Machinery | Carbon Steel | Mazak HCN-5000 | 400 units/month | 7 |

| Electronics Housing | Aluminum | OKUMA MB-4000H | 1000 units/month | 4 |

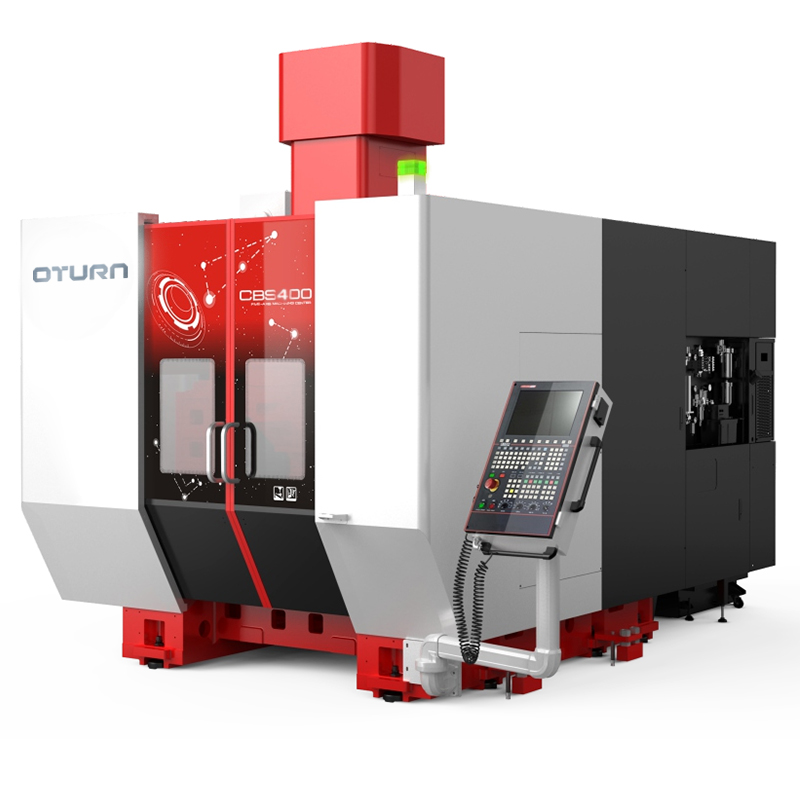

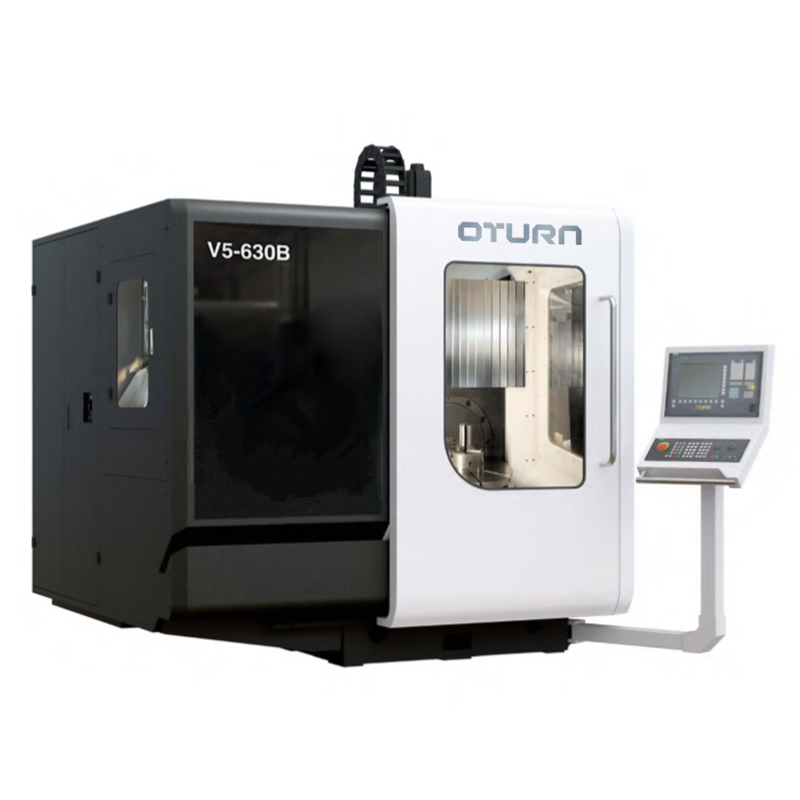

Related Products