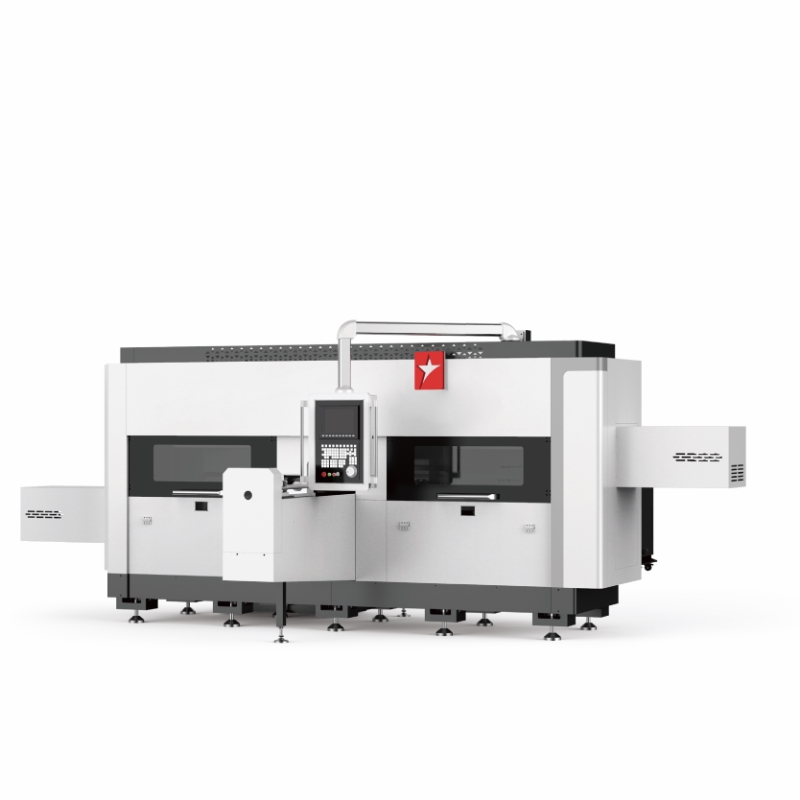

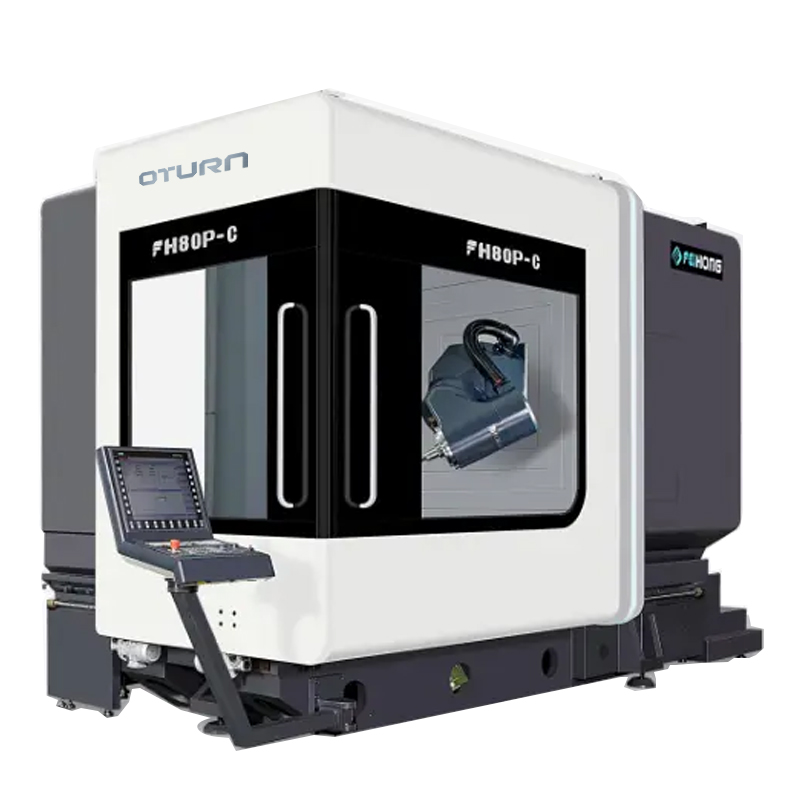

Cnc Gear Hobbing Machine Manufacturer in China - Quality & Precision

When I think of precision and efficiency in gear manufacturing, the CNC gear hobbing machine stands out. Made in China, these machines offer unbeatable quality at a competitive price, making them a top choice for manufacturers around the world. I've seen firsthand how these machines elevate production capabilities, allowing for high accuracy and reduced waste. The versatility of CNC gear hobbing machines cater to various gear sizes and types, ensuring that whatever your project demands, this technology meets it effortlessly. As a manufacturer, I appreciate the ease of integration into existing workflows and the durability that comes with each unit. Plus, ongoing support from Chinese manufacturers ensures that help is always a call away. If you're serious about improving your gear production, investing in a CNC gear hobbing machine can truly transform your operations.

Cnc Gear Hobbing Machine Is The Best From Concept to Delivery

When it comes to precision manufacturing, the CNC gear hobbing machine stands out as an essential tool for producing high-quality gears efficiently. From concept to delivery, this advanced machinery offers unparalleled accuracy and versatility, making it a preferred choice for industries worldwide. With the ability to handle various gear profiles and materials, it empowers manufacturers to meet diverse client requirements while ensuring high productivity. The design of the CNC gear hobbing machine leverages cutting-edge technology to enhance both performance and reliability. Features such as programmable controls enable operators to achieve intricate designs with precision, significantly reducing lead times. This capability is particularly beneficial for global buyers looking to streamline their production processes without compromising on the quality of their products. As demands for precision and efficiency increase, investing in these advanced machines can lead to significant improvements in operational performance and cost-effectiveness. By embracing these innovative solutions, manufacturers can better position themselves in the competitive landscape. The ability to provide tailored gear solutions while maintaining strict quality standards not only satisfies customer expectations but also fosters long-term partnerships. As industries evolve, prioritizing the best technological tools will be key to sustaining growth and driving success in the global marketplace.

Cnc Gear Hobbing Machine Is The Best From Concept to Delivery

| Specification | Details | Advantages | Applications |

|---|---|---|---|

| Spindle Speed | 1000 - 3000 RPM | High precision and efficiency | Automotive gears, industrial machinery |

| Gear Module Range | 1 - 10 mm | Flexible customization options | Aerospace, robotics |

| Max Gear Diameter | 400 mm | Suitable for larger components | Heavy machinery, construction |

| Weight | 1500 kg | Stable and robust performance | Machine tool industry |

| Control System | CNC with user-friendly interface | Ease of operation and programming | Custom machining solutions |

Related Products