CNC Gantry Type Machining Center Manufacturer in China | Precision Solutions

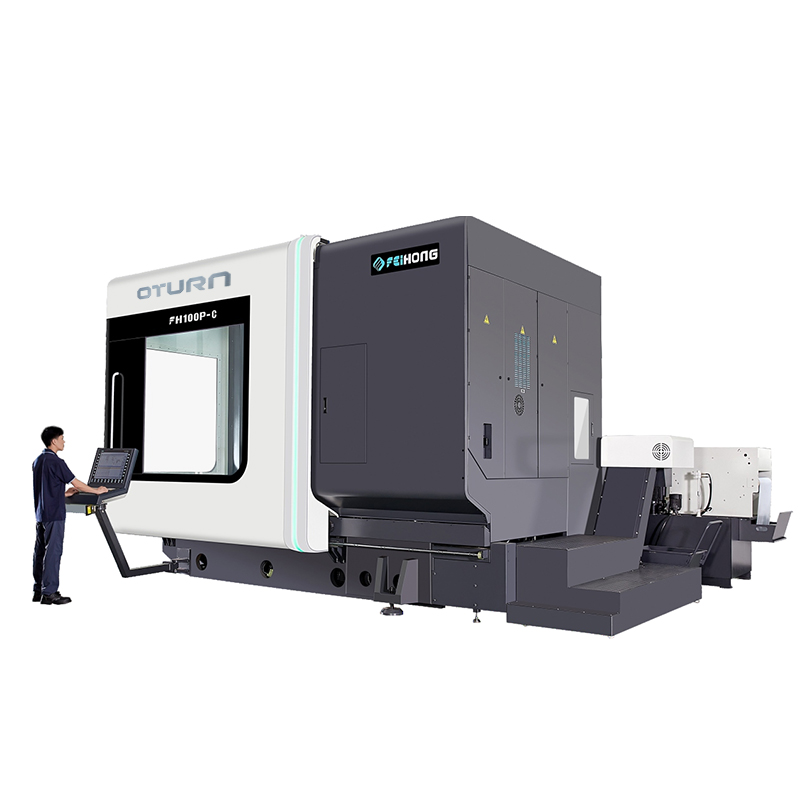

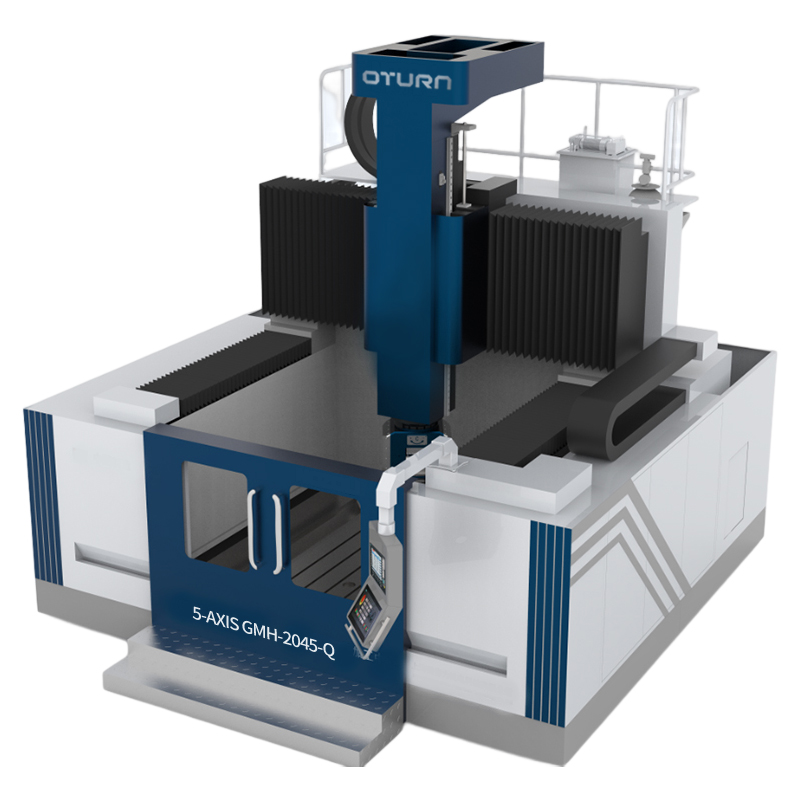

When it comes to precision engineering, my CNC Gantry Type Machining Center stands out in the market. Manufactured in China, this advanced machining center is designed for superior performance and efficiency. I've seen firsthand how it streamlines production processes while maintaining tight tolerances, making it ideal for various industries like aerospace, automotive, and heavy machinery. As a manufacturer, I understand that durability and reliability are crucial for your operations. That’s why my machining center is built with robust materials and cutting-edge technology, ensuring long-lasting performance even in the most demanding environments. With user-friendly controls and customizable features, it’s not just a machine; it's a partner that helps you enhance your productivity. If you’re ready to invest in quality and efficiency, let’s connect and see how my CNC Gantry Type Machining Center can meet your manufacturing needs. You won't be disappointed!

Cnc Gantry Type Machining Center Supplies the World\u2019s Top Brands Factory-Direct Excellence

In today's competitive manufacturing landscape, the demand for high-quality machining centers is on the rise, especially for CNC gantry type machines that combine precision and efficiency. These advanced systems are integral in meeting the rigorous demands of various industries, from aerospace to automotive, providing unparalleled performance that top brands rely on. With their robust design and superior accuracy, CNC gantry machining centers are capable of handling large workpieces with ease, making them a favorable choice for businesses aiming to enhance their production capabilities. As global buyers look to source reliable machinery, the appeal of factory-direct excellence cannot be overstated. By purchasing directly from manufacturers, buyers can ensure they receive not only competitive pricing but also access to comprehensive support and expertise. This direct relationship between the buyer and manufacturer fosters a deeper understanding of product specifications and operational requirements, ultimately leading to informed purchasing decisions that align with strategic business goals. Moreover, investing in top-tier CNC gantry machines signifies commitment to innovation and quality. Companies that prioritize these superior machines will likely see improvements in their operational efficiencies and product output. In a world where precision and speed are paramount, sourcing advanced machinery can provide a significant competitive edge, enabling businesses to stay ahead in a rapidly evolving market. Embrace the future of manufacturing with cutting-edge CNC technology and watch your production capabilities soar.

Cnc Gantry Type Machining Center Supplies the World’s Top Brands Factory-Direct Excellence

| Specification | Feature | Application | Customization Options |

|---|---|---|---|

| XYZ Travel: 2000 x 1000 x 500 mm | High precision direct drive system | Aerospace components | Custom axis configurations |

| Spindle Power: 15 kW | Variable speed control | Automotive parts manufacturing | Special tooling attachments |

| Weight: 5000 kg | Robust structure for stability | Industrial machinery | Automated features |

| Control System: CNC with Touch Screen | User-friendly interface | Metalworking | Software integration options |

| Working Speed: Up to 20 m/min | High-speed machining | Prototyping | Color and finish customizations |

Related Products