China Heavy Duty Lathe Manufacturer: Quality & Precision for Industries

When it comes to precision and durability, I trust the China Heavy Duty Lathe for my machining needs. Perfect for heavy industrial applications, these machines stand out in terms of performance and reliability. As a manufacturer from China, they prioritize craftsmanship, ensuring each lathe meets rigorous quality standards. I find that their robust design allows for tackling tough jobs while maintaining accuracy, which is essential in today’s competitive market. With a variety of models available, I can easily find one that fits my specific requirements. The user-friendly interface and advanced features make operation straightforward, even for complex tasks. I appreciate that these heavy-duty lathes are built to last, with top-notch materials that withstand the test of time. Investing in a China Heavy Duty Lathe means choosing a machine that not only enhances productivity but also delivers consistent results. If you're serious about machining, this is a brand worth considering.

China Heavy Duty Lathe Application From Concept to Delivery

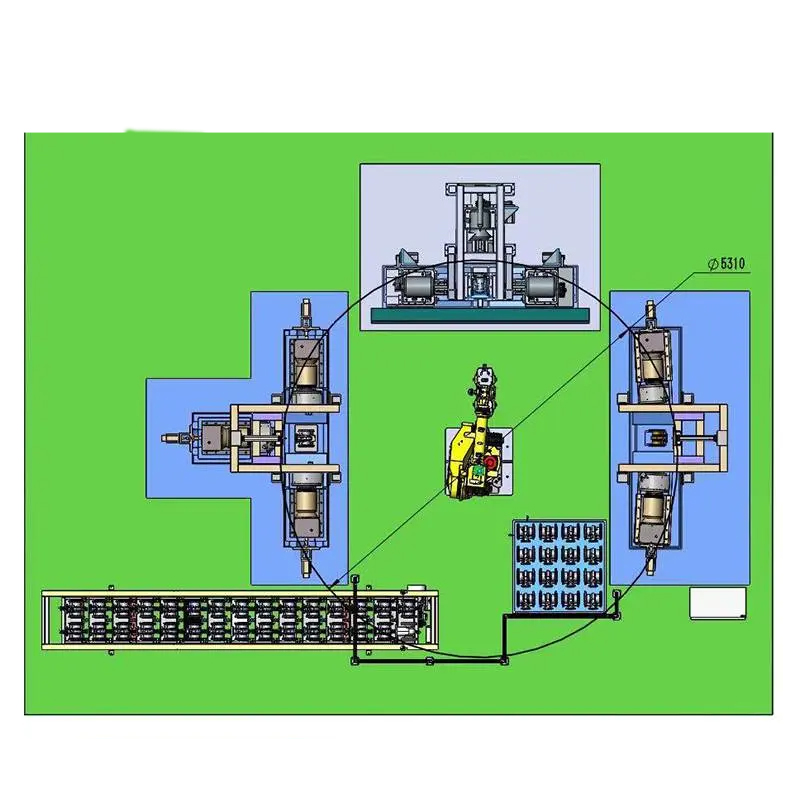

The heavy-duty lathe represents the backbone of precision machining and is pivotal for various industries, including automotive, aerospace, and heavy equipment manufacturing. From the initial concept phase to the final delivery, the development of heavy-duty lathes involves meticulous planning, engineering expertise, and robust manufacturing processes. This journey begins with understanding client specifications and requirements, ensuring that every machine is tailored to meet the unique demands of different applications. Advanced technologies play a crucial role in the design and production of heavy-duty lathes. Utilizing CAD software and simulation tools, engineers can create innovative designs that enhance performance and efficiency. Furthermore, the integration of CNC technology allows for increased automation and precision, resulting in superior machining capabilities. As the manufacturing process unfolds, quality control measures are implemented at every stage to guarantee that each lathe meets stringent international standards. Once production is completed, the logistics of delivery are carefully managed to ensure timely arrival at the client's location. This phase includes comprehensive packaging solutions and coordination with global shipping partners. The ultimate goal is to provide customers with not only a high-quality machine but also an exceptional purchasing experience. By prioritizing durability and performance, the heavy-duty lathe is set to become an invaluable asset in production facilities worldwide.

China Heavy Duty Lathe Application From Concept to Delivery

| Application Area | Lathe Type | Specification | Material Processed | Delivery Time |

|---|---|---|---|---|

| Steel Manufacturing | CNC Lathe | 1000mm swing, 3000mm bed length | Carbon Steel | 8 weeks |

| Aerospace Components | Manual Lathe | 800mm swing, 2000mm bed length | Aluminum Alloy | 10 weeks |

| Heavy Machinery Parts | Horizontal Lathe | 1200mm swing, 4000mm bed length | Cast Iron | 12 weeks |

| Oil and Gas Industry | Vertical Lathe | 1500mm swing, 5000mm bed length | Stainless Steel | 14 weeks |

| Automotive Parts | CNC Lathe | 900mm swing, 2500mm bed length | High-strength Steel | 9 weeks |

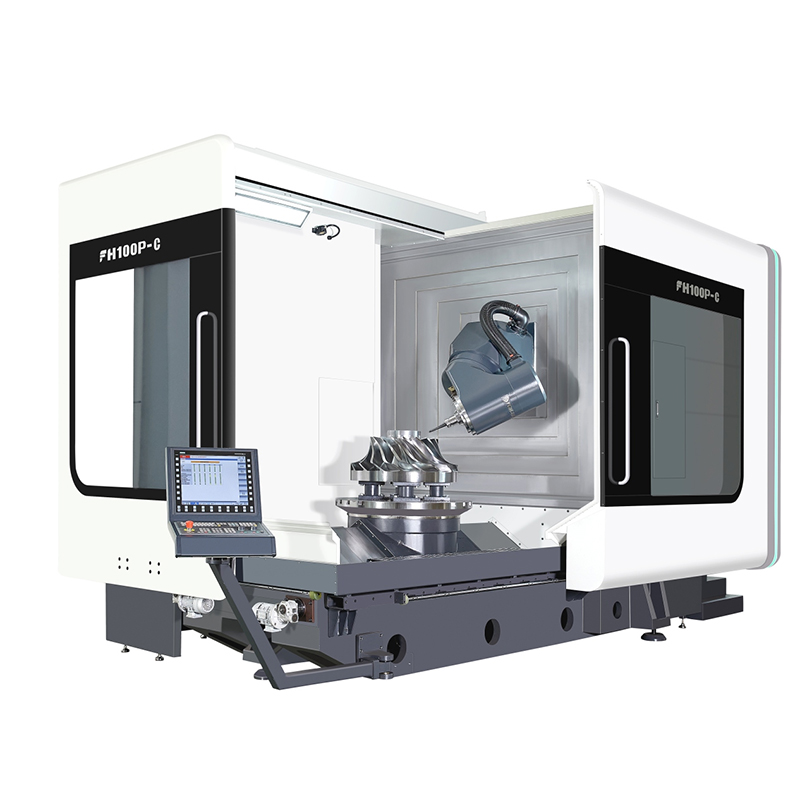

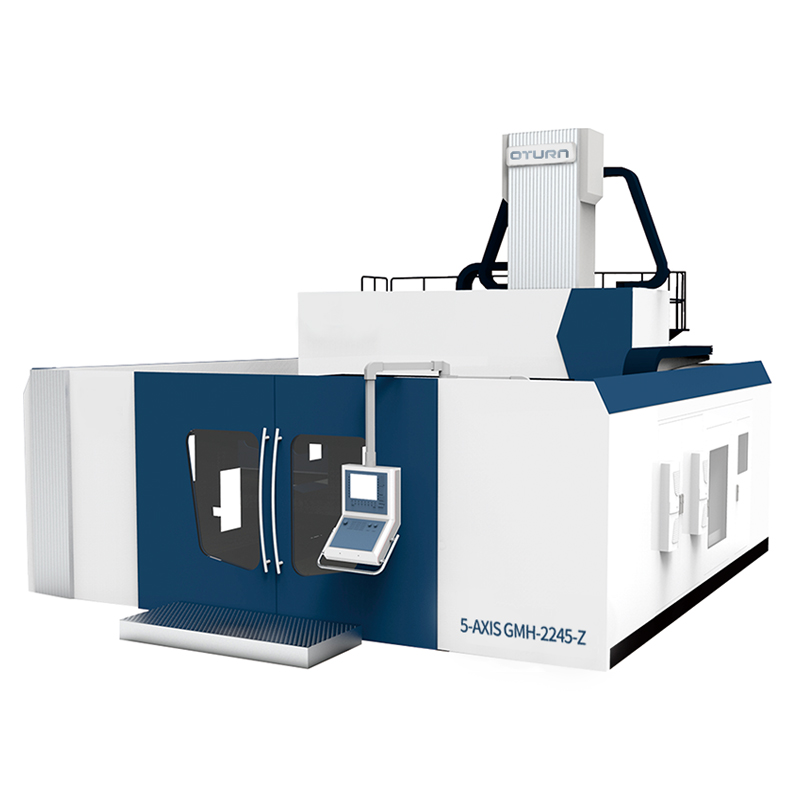

Related Products