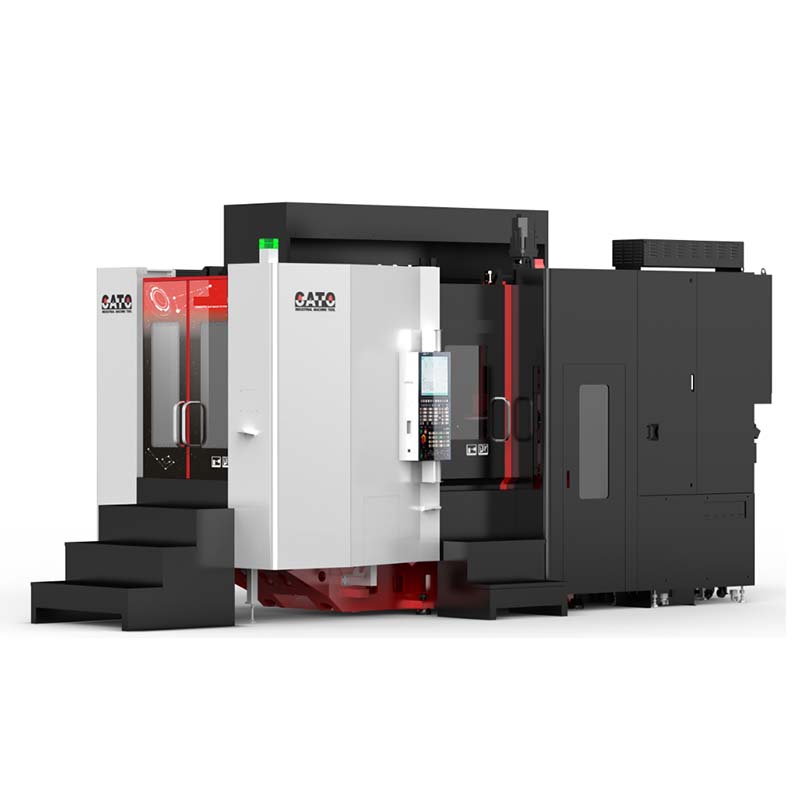

Top China CNC Lathe Manufacturers for Precision Machining Solutions

When it comes to precision and reliability, I trust the China CNC lathe for my machining needs. As a manufacturer, this equipment offers exceptional quality and durability, designed to handle a wide array of materials. With advanced features and cutting-edge technology, these lathes empower me to achieve intricate designs and superior finishes with ease. What stands out to me is the competitive pricing without sacrificing performance. The versatility of China CNC lathes allows me to optimize my production processes, making them perfect for both small batches and large-scale operations. Whether I'm producing components for automotive or aerospace industries, the efficiency and accuracy I get is unmatched. If you're considering upgrading your machinery, I can confidently recommend investing in a China CNC lathe. It’s not just an equipment purchase; it’s a step towards boosting your production capability and maintaining a competitive edge in the market.

China Cnc Lathe Application From Concept to Delivery

In the ever-evolving landscape of manufacturing, CNC lathes have emerged as essential tools for precision engineering across various industries. From concept to delivery, the application of CNC lathe technology transforms ideas into tangible products, streamlining production processes and enhancing product quality. The integration of advanced computer numerical control allows for automation and increased efficiency, significantly reducing production time while maintaining exceptional accuracy. For global buyers seeking reliability and innovation, understanding the stages of CNC lathe application is crucial. It begins with a detailed consultation to assess specific machining needs, followed by the design phase, where customization options are explored. During production, cutting-edge technology ensures that every component meets stringent quality standards. Rigorous testing and inspection phases guarantee that the final product not only meets design specifications but also adheres to safety regulations. As businesses move towards greater customization and shorter lead times, partnering with manufacturers that excel in CNC lathe applications can be a game-changer. The transition from concept to delivery is streamlined through effective project management, ensuring that customers receive high-quality products tailored to their precise requirements, ultimately fostering lasting partnerships and driving mutual growth.

China Cnc Lathe Application From Concept to Delivery

| Application Area | Material Type | Machine Model | Precision Level | Cycle Time (minutes) | Delivery Time (days) |

|---|---|---|---|---|---|

| Automotive Parts | Aluminum | CNC-1000 | ±0.01 mm | 30 | 15 |

| Aerospace Components | Titanium | CNC-2000 | ±0.005 mm | 45 | 20 |

| Medical Device Manufacturing | Stainless Steel | CNC-3000 | ±0.01 mm | 25 | 10 |

| Electronics Housing | Plastic | CNC-4000 | ±0.02 mm | 15 | 5 |

| Industrial Machinery | Carbon Steel | CNC-5000 | ±0.01 mm | 50 | 30 |

Related Products