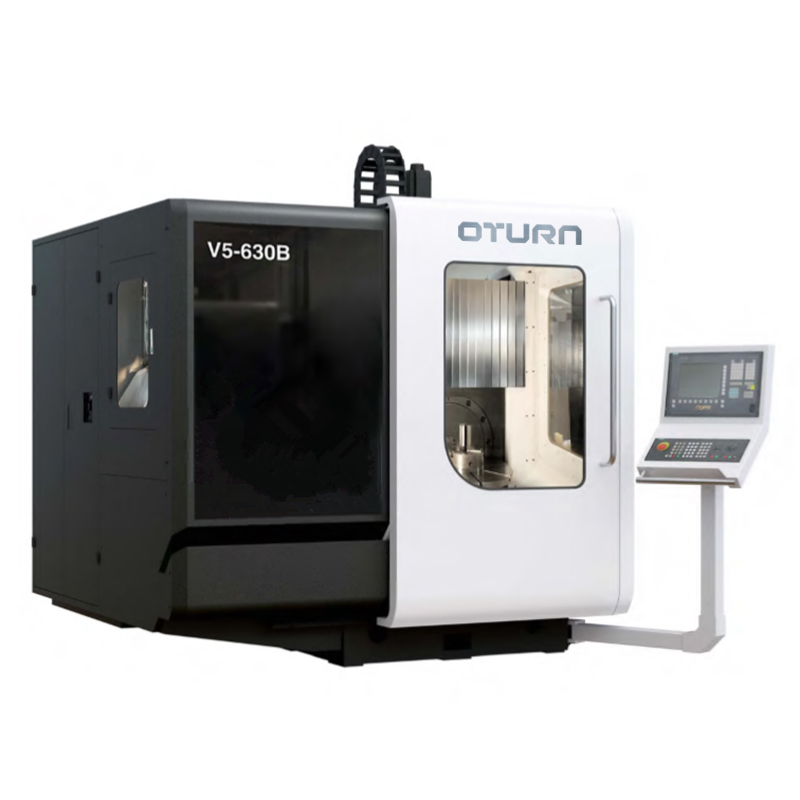

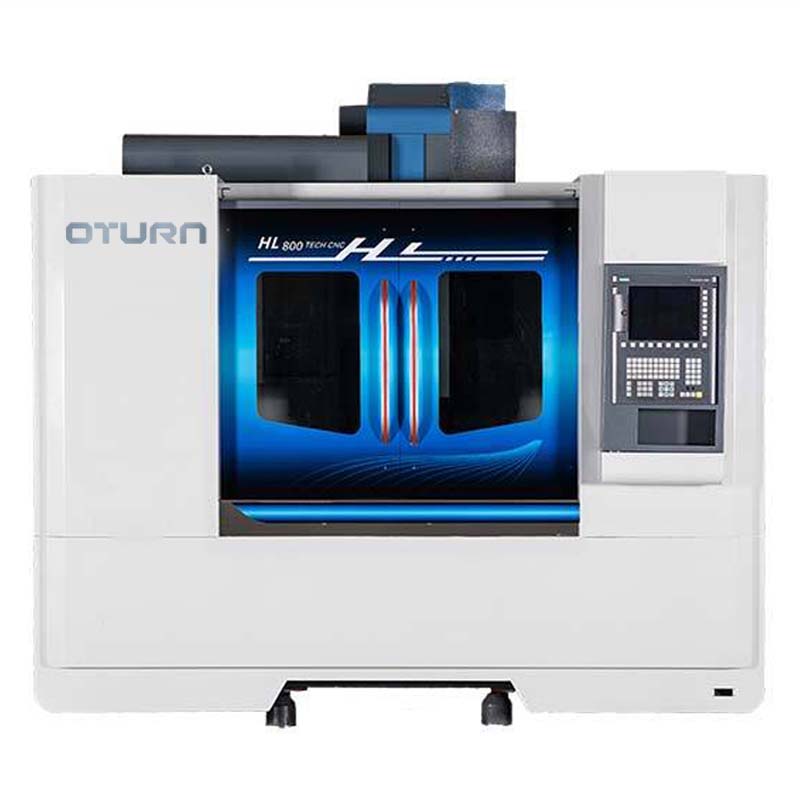

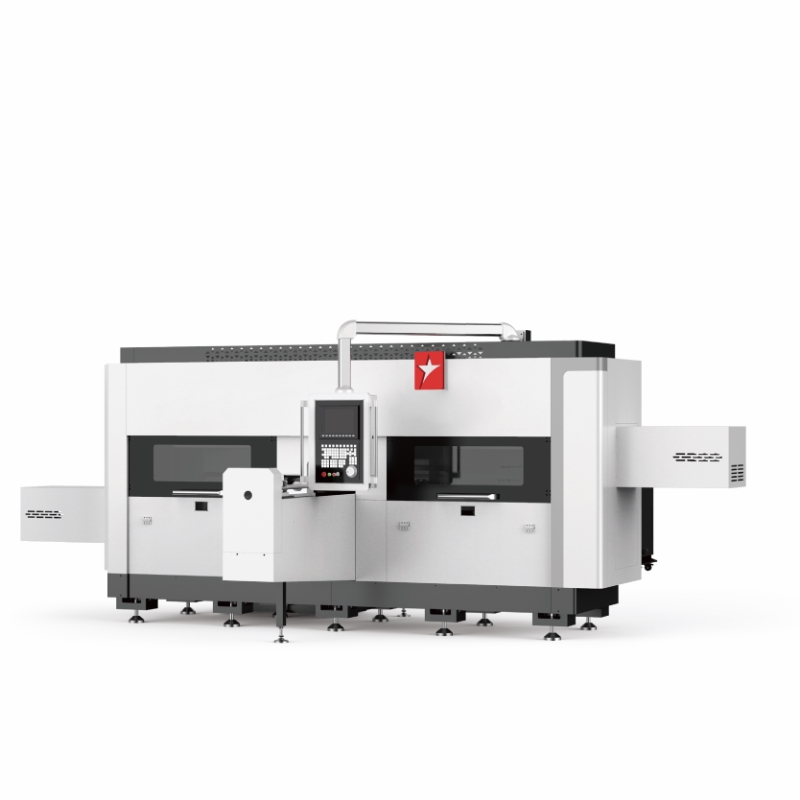

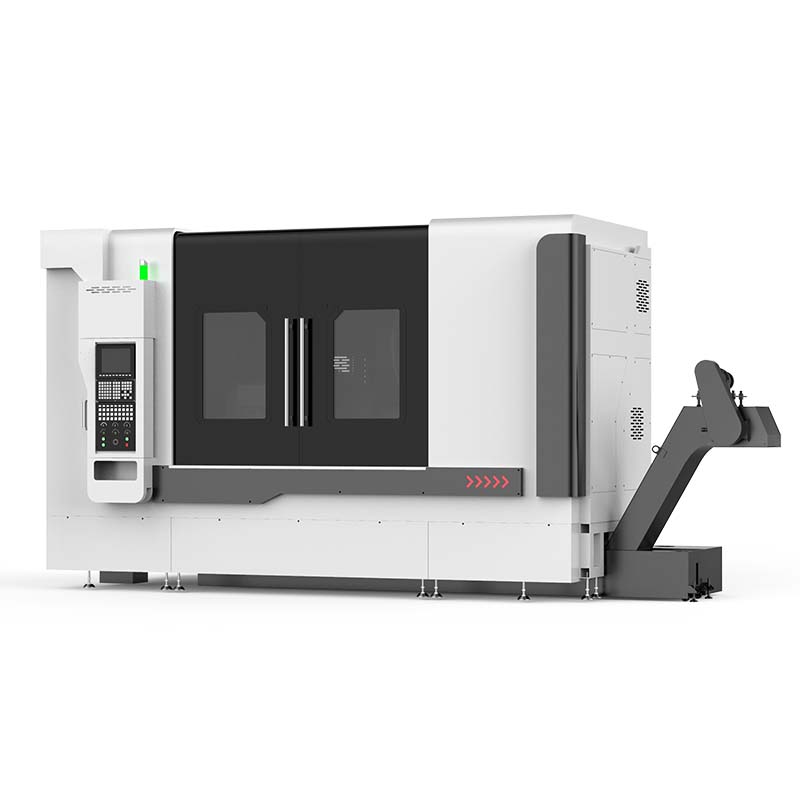

Top China Manufacturer of 5 Axis Vertical Machining Centers

When I think about precision engineering, the **5 Axis Vertical Machining Center** stands out as a game-changer. As a manufacturer based in China, I ensure each machine is built to deliver unmatched accuracy and efficiency. This machining center allows for complex geometries to be crafted in a single setup, dramatically reducing production time and improving part quality. With advanced technology integrated into its design, it excels in high-speed machining and offers incredible flexibility across various materials. Whether you're in aerospace, automotive, or medical industries, our 5 Axis Vertical Machining Center fits your needs perfectly. Quality, durability, and performance are what I promise when you choose my equipment. Investing in this machine means investing in the future of your production capabilities. Let's elevate your manufacturing process together!

5 Axis Vertical Machining Center Factory-Direct Excellence Service Backed by Expertise

In the evolving landscape of manufacturing, the demand for precision and efficiency is paramount. A 5 Axis Vertical Machining Center stands at the forefront of this revolution, offering unparalleled capabilities for complex machining tasks. These machines are designed to deliver precision in multi-dimensional work, enabling businesses to tackle intricate designs and innovative projects with ease. When sourcing from a reliable factory, it’s essential to consider not just the machinery but also the level of service and expertise that comes with it. With factory-direct excellence, customers gain the advantage of direct communication and streamlined processes, ensuring that every machine is tailored to their specific needs. Experienced professionals are on hand to provide insights and support, guaranteeing that clients make informed decisions and maximize their investments. Comprehensive service packages, including installation, training, and ongoing maintenance, reinforce a commitment to customer satisfaction, ensuring that your operations run smoothly and efficiently. Choosing the right partner means accessing cutting-edge technology backed by years of industry experience. As global markets demand higher levels of production quality and efficiency, investing in a 5 Axis Vertical Machining Center can provide a significant competitive edge. Embrace innovation, cultivate expertise, and elevate your production capabilities through strategic partnerships that prioritize excellence and customer service.

5 Axis Vertical Machining Center Factory-Direct Excellence Service Backed by Expertise

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| High Precision | Offers accurate machining with minimal tolerances. | Enhances product quality and reduces waste. | Aerospace, Automotive, Medical Parts |

| Complex Geometry | Capable of machining intricate designs and contours. | Increases design flexibility and innovation. | Molds, Tooling, Custom Components |

| User-Friendly Interface | Intuitive controls for easier operation. | Reduces training time and increases productivity. | Prototype Development, Short Runs |

| Durable Construction | Built with robust materials for long-lasting use. | Minimizes maintenance costs and downtime. | Heavy Industry, High-Volume Production |

| Energy Efficient | Designed to reduce power consumption. | Lowers operating costs and environmental impact. | General Manufacturing, Sustainability Initiatives |

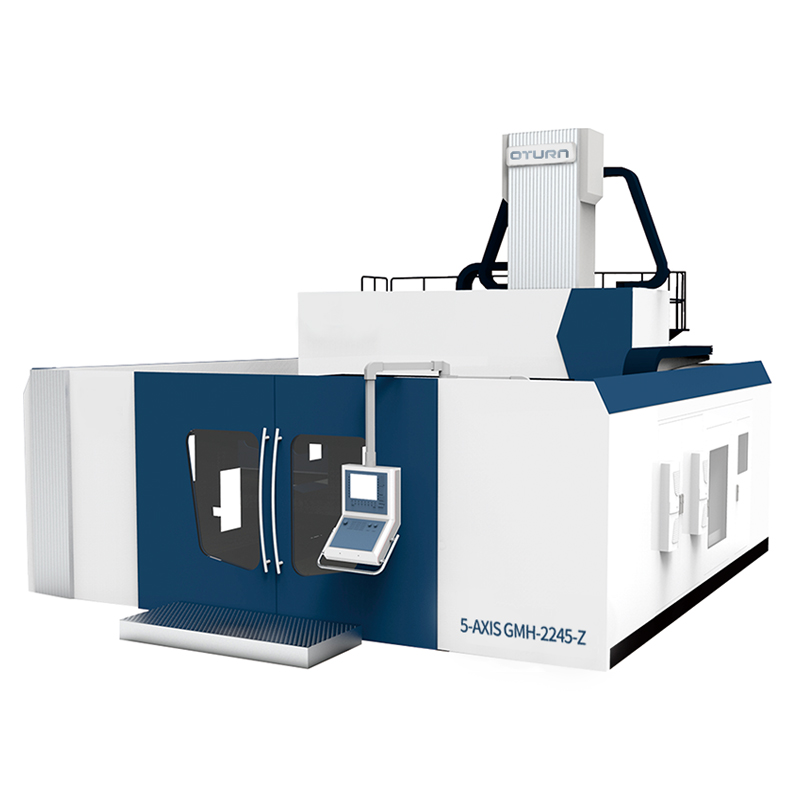

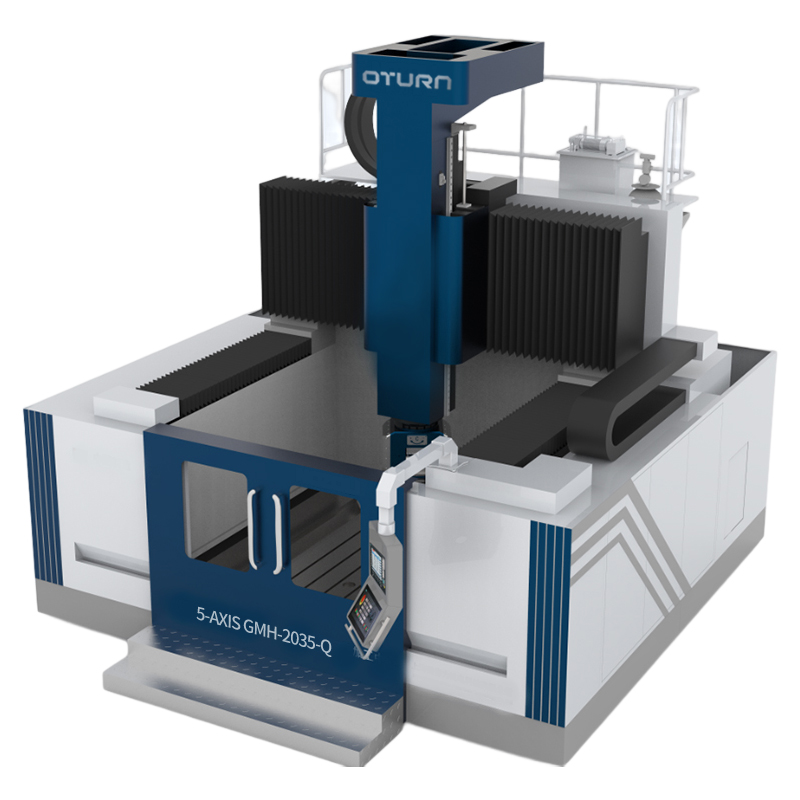

Related Products