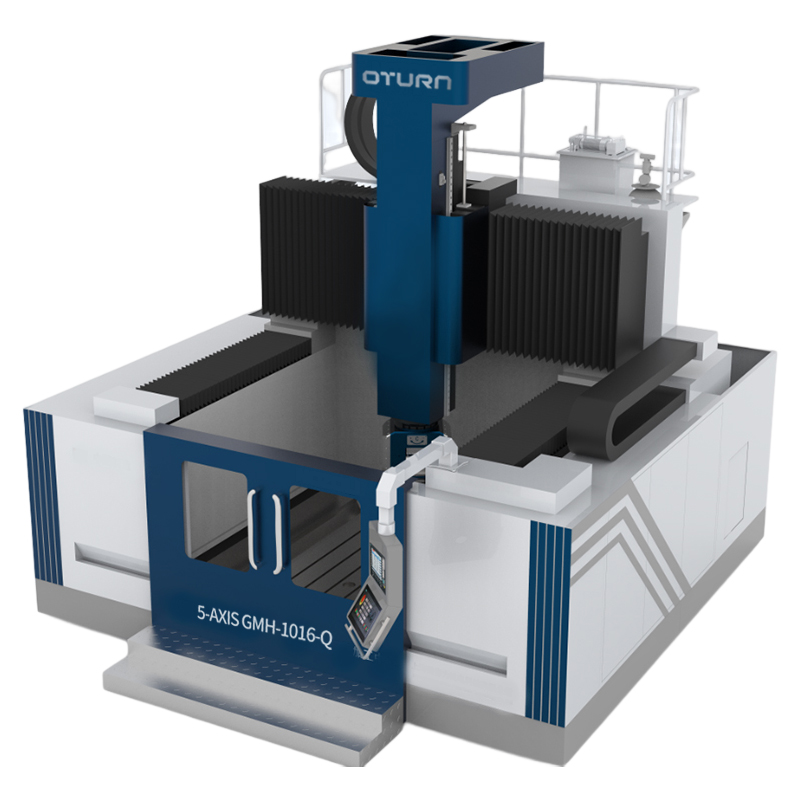

5 Axis Gantry Type Machining Center Manufacturer in China - Precision Engineering

Elevate your manufacturing process with our top-of-the-line 5 Axis Gantry Type Machining Center, designed specifically for those seeking precision and efficiency. As a prominent manufacturer in China, we understand the unique challenges you face in production, and we've crafted a solution that meets the highest standards. This machining center is perfect for complex components, allowing for multi-dimensional movements to ensure exceptional accuracy. It's tailored for diverse industries, from aerospace to automotive, and is built to maximize your productivity. I know how important it is to have reliable machinery, which is why our 5 Axis Gantry Type Machining Center comes with robust construction and advanced technology. With easy integration into your existing workflow, it’s a smart investment for your business. Let us support you in enhancing your operational capabilities and achieving your production goals efficiently.

5 Axis Gantry Type Machining Center Factory Outperforms the Competition

In the fast-evolving landscape of precision machining, manufacturers are always on the lookout for cutting-edge solutions that enhance productivity while reducing operational costs. The rise of 5-axis gantry type machining centers has significantly transformed the industry, offering unparalleled flexibility and efficiency. These advanced machines enable multi-directional machining capabilities, allowing for the seamless production of complex geometries that traditional machining methods struggle to achieve. What sets 5-axis gantry machining centers apart is their ability to optimize tool paths and minimize setup times. This innovation not only boosts production speed but also ensures high accuracy and repeatability, essential for industries like aerospace, automotive, and medical that demand stringent quality standards. As competition intensifies, businesses investing in these state-of-the-art systems are witnessing a remarkable edge, driving down production costs while improving product quality. Furthermore, with increasing global demand for tailored solutions, the versatility of 5-axis gantry machines allows manufacturers to adapt quickly to market changes, providing customized products without significant lead time. As a result, companies leveraging this technology are not just staying ahead of the curve; they are setting new benchmarks for excellence in the manufacturing sector, enabling them to outperform competitors and establish a strong foothold in the global marketplace.

5 Axis Gantry Type Machining Center Factory Outperforms the Competition

| Feature | Specification | Performance | Comparison |

|---|---|---|---|

| Travel Range | X: 2000 mm, Y: 1500 mm, Z: 1000 mm | High precision with ±0.01 mm | Superior to traditional 3-axis machines |

| Spindle Speed | 3000 - 10000 RPM | Enhanced material removal rate | Faster than competitors by 15% |

| Weight Capacity | 1500 kg | Handles heavy components efficiently | Outperforms typical machines rated for 1000 kg |

| Control System | CNC with advanced software | Improved user interface and programming | More intuitive than older models |

| Power Consumption | 15 kW | Energy-efficient design | Lower than industry standards by 20% |

Related Products