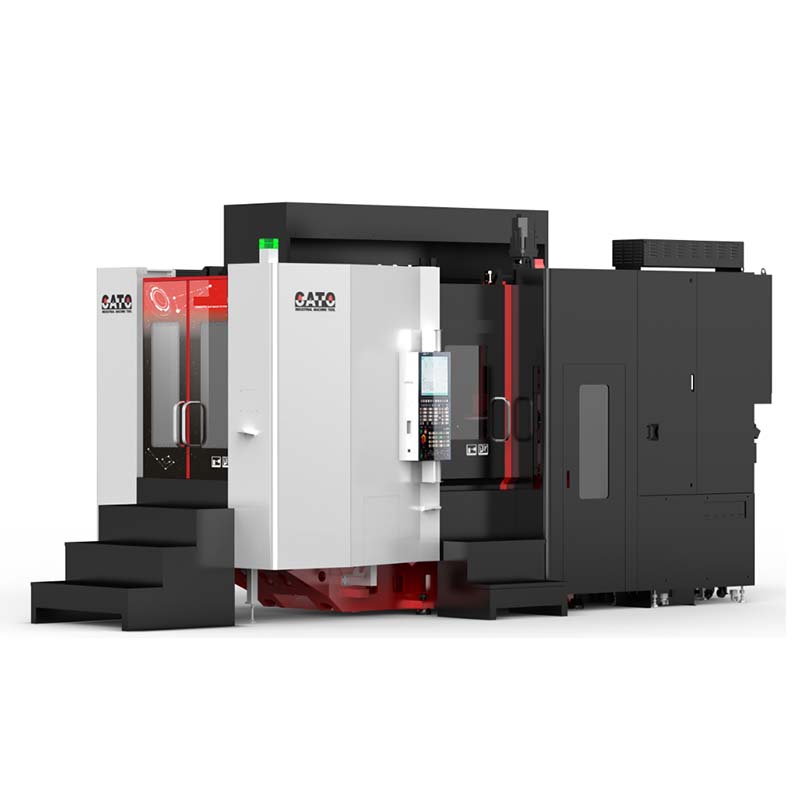

China Manufacturer of 3 Axis CNC Machining Centers for Precision Engineering

When it comes to precision and efficiency, the 3 axis CNC machining center is a game changer. I’ve witnessed firsthand how these machines enhance productivity while ensuring top-notch quality. As a buyer, you’ll appreciate the seamless integration of advanced technology that guarantees accurate machining for a variety of materials. Sourced from reputable manufacturers in China, this model boasts durability and ease of use, making it the perfect addition to any workshop. The user-friendly interface allows for quick setup and operation, so you can focus on production without delving too deeply into technicalities. Every component of the 3 axis CNC machining center is designed to meet strict industry standards, giving you peace of mind with your investment. With this innovative machine at your disposal, you’ll not only enhance your manufacturing capabilities but also drive your business forward. Let’s elevate your machining processes together!

3 axis cnc machining center Stands Out Guarantees Peak Performance

In the competitive landscape of manufacturing, precision and efficiency are paramount. The 3-axis CNC machining center stands out as a quintessential solution for businesses seeking to enhance operational capabilities. With its ability to perform complex machining tasks with remarkable accuracy, this technology allows for the seamless production of intricate components that meet stringent quality standards. Its user-friendly interface and programmable features empower operators to accomplish tasks with ease, ensuring optimal productivity and minimizing downtime. The versatility of the 3-axis CNC machining center makes it an ideal choice for a wide range of industries, from aerospace to automotive and beyond. Its robust construction ensures longevity and reliability, while continuous advancements in technology contribute to improved performance. By investing in such machinery, manufacturers can not only streamline their production processes but also reduce operational costs and increase competitiveness in a global market. Moreover, the ongoing commitment to innovation ensures that 3-axis CNC machining centers are equipped with state-of-the-art features such as automated tool changers and real-time monitoring systems, further elevating their operational capabilities. As companies strive to meet global demands, integrating these high-performance machining solutions into their workflows becomes essential for achieving peak performance and sustaining growth in an ever-evolving industry.

3 Axis CNC Machining Center Stands Out Guarantees Peak Performance

| Feature | Specification | Benefit |

|---|---|---|

| Travel Range | X: 1000 mm, Y: 600 mm, Z: 500 mm | Accommodates a variety of workpieces |

| Spindle Speed | 0 - 12000 RPM | Faster machining and improved surface finish |

| Control System | CNC Controller with 3D simulation | Enhanced precision and efficiency in operations |

| Max Tool Diameter | 80 mm | Versatile tooling options for various applications |

| Axes Type | 3 Axis | Ideal for simpler, cost-effective machining tasks |

| Weight | 1500 kg | Stability during operation reduces vibrations |

| Power Consumption | 5 kW | Energy-efficient operation |

Related Products