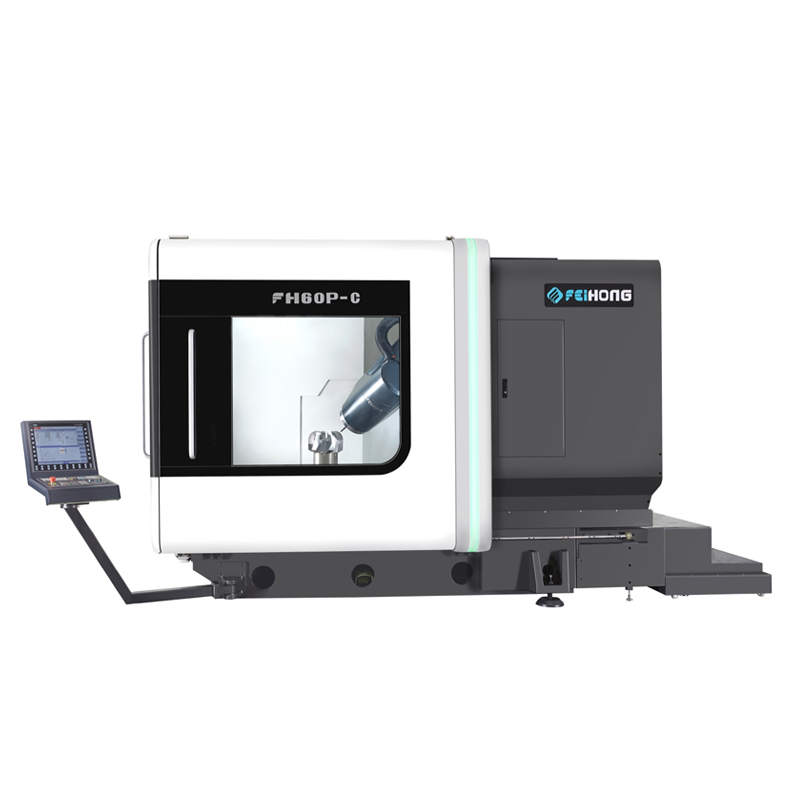

VTL Lathe from Top Manufacturer in China: Precision and Quality Assured

Are you in need of a high-quality VTL lathe? As a seasoned manufacturer based in China, we understand the unique requirements of businesses like yours. Our VTL lathes are engineered to deliver precision and durability, making them ideal for a range of applications. I’ve seen firsthand how our machines can significantly enhance your production efficiency, allowing you to meet tight deadlines without compromising on quality. With advanced features and user-friendly controls, our VTL lathes cater to various industries, ensuring you get the best value for your investment. I pride myself on the level of customer support we offer, guiding you through the selection process and beyond. Consider our service as an extension of your team, dedicated to your success. If you're ready to elevate your manufacturing capabilities, let’s talk about how our VTL lathes can meet your needs and help drive your business forward.

Vtl Lathe Industry Leaders Custom Solutions,

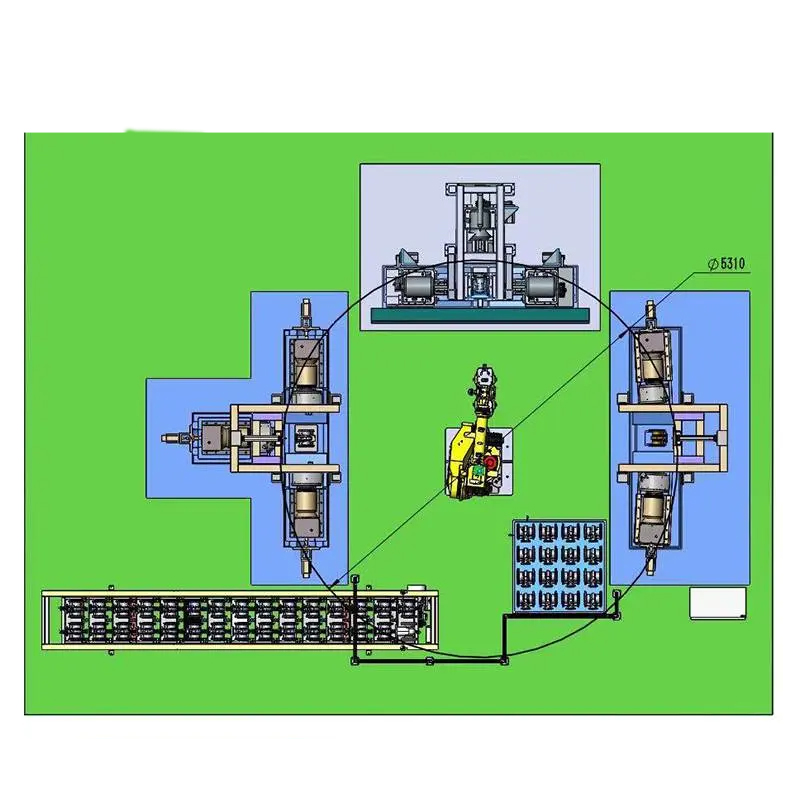

In today's competitive manufacturing landscape, the demand for precision and customization continues to rise. Businesses around the globe seek reliable partners who can provide tailored solutions to meet their unique operational needs. The VTL lathe industry stands out as a key player in delivering advanced machining solutions, enabling manufacturers to achieve high-quality standards and operational efficiency. Custom solutions in the VTL lathe sector can significantly enhance production capabilities. By leveraging advanced technologies and expert craftsmanship, industry leaders offer lathes that adapt to specific materials, sizes, and production volumes. This flexibility not only maximizes the throughput but also minimizes waste, aligning with sustainability goals that are essential for many modern enterprises. Collaborating with experts in this field allows global purchasers to gain a competitive edge, ensuring their manufacturing processes are both cost-effective and innovative. Investing in customized VTL lathes can lead to substantial long-term benefits. As demands fluctuate and new market opportunities arise, having machinery that can quickly adjust to changing requirements becomes invaluable. Industry leaders are committed to understanding client processes, providing not just machines, but comprehensive solutions that contribute to overall operational success. Embracing these bespoke machineries can ultimately drive growth and enhance product offerings in an ever-evolving market.

Vtl Lathe Industry Leaders Custom Solutions

| Dimension | Material | Tolerance | Finish | Lead Time |

|---|---|---|---|---|

| 100x100x300 mm | Steel | ±0.05 mm | Machined | 4 weeks |

| 150x150x500 mm | Aluminium | ±0.02 mm | Anodized | 6 weeks |

| 200x200x400 mm | Brass | ±0.03 mm | Polished | 5 weeks |

| 120x80x300 mm | Carbon Steel | ±0.05 mm | Black Oxide | 3 weeks |

| 250x250x600 mm | Stainless Steel | ±0.01 mm | Brushed | 8 weeks |

Related Products