Top China Manufacturer of Vertical Turning Center Machines for Precision

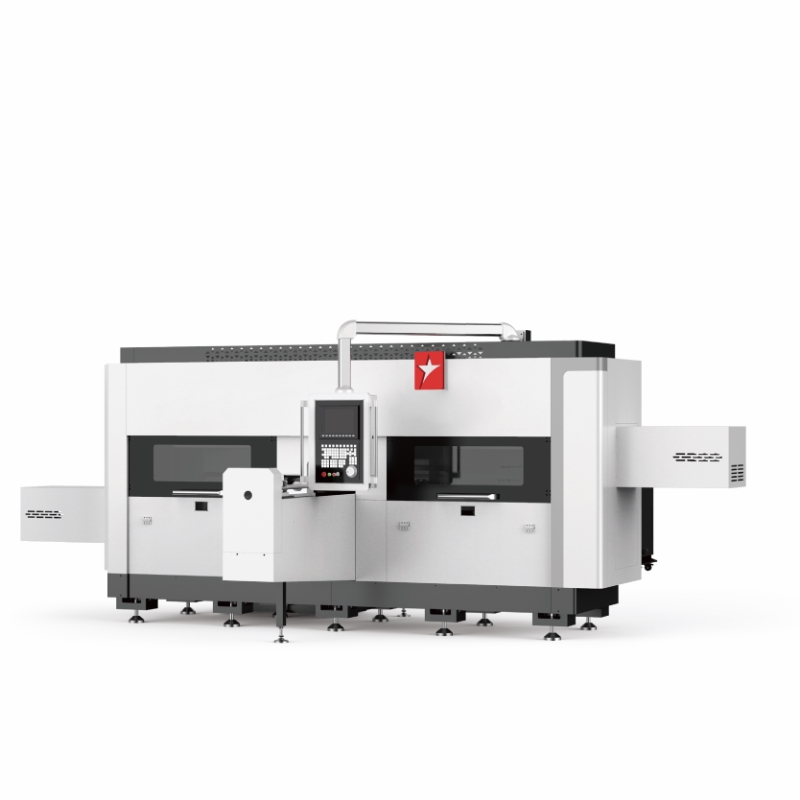

When it comes to precision and efficiency, our Vertical Turning Center Machine stands out as a top choice for manufacturers in China. I know how crucial it is for businesses to find reliable machinery that can enhance productivity while ensuring top-notch quality. This machine seamlessly combines advanced technology with user-friendly features, making it perfect for a range of machining applications. With robust construction and high-speed capabilities, it accommodates various materials and complex designs, helping your production processes run smoother than ever. As a manufacturer dedicated to innovation, we focus on meeting the specific needs of our clients, providing tailored solutions that can drive growth and profitability. If you’re on the hunt for a Vertical Turning Center Machine that delivers precision and durability, let’s connect. Upgrading your machinery can significantly impact your operations, and we're here to support your journey with our expertise and industry knowledge.

Vertical Turning Center Machine Factory in 2025

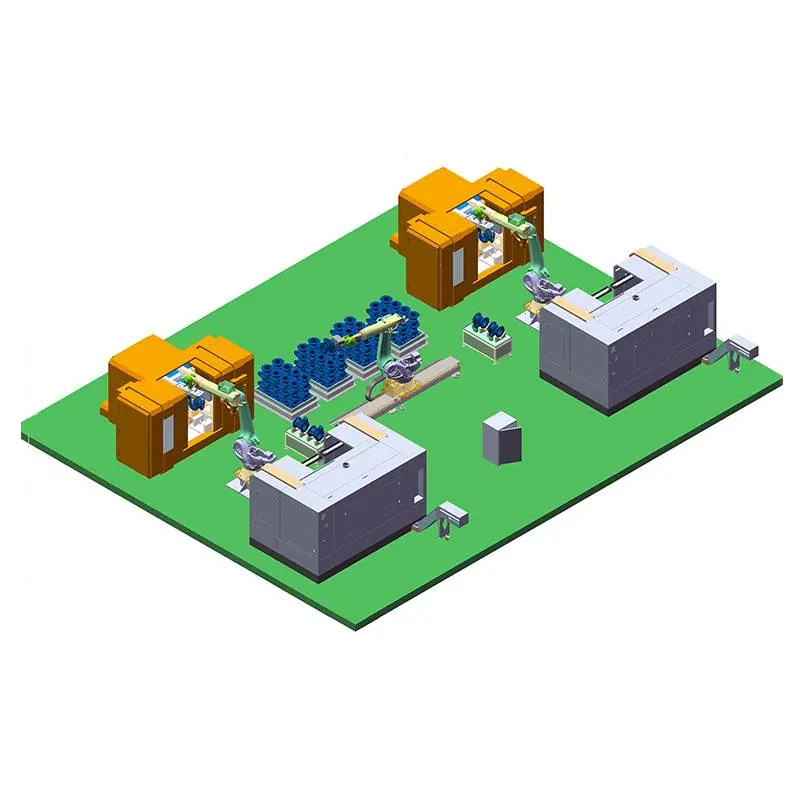

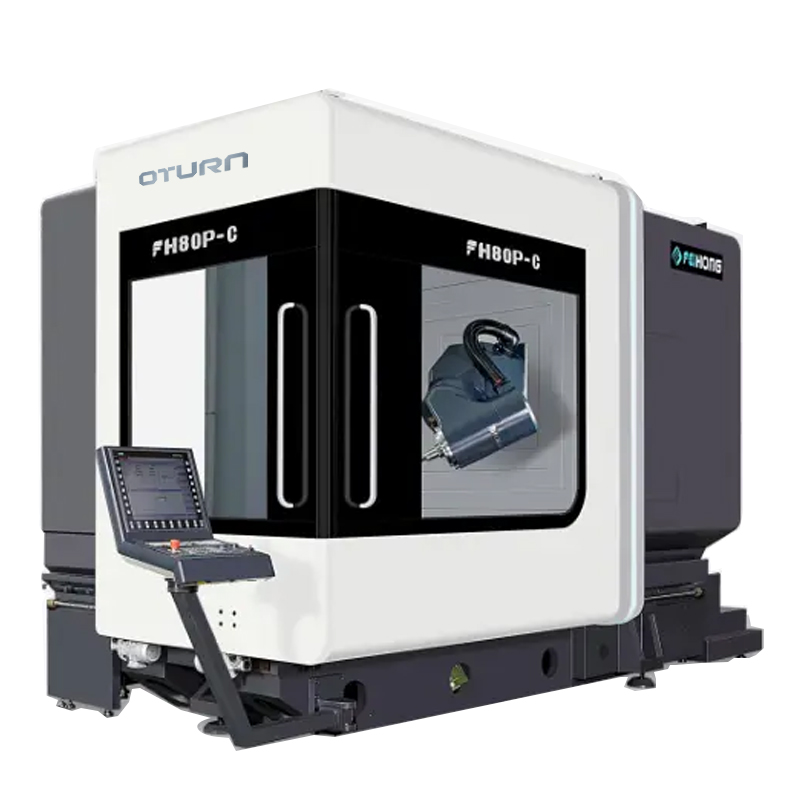

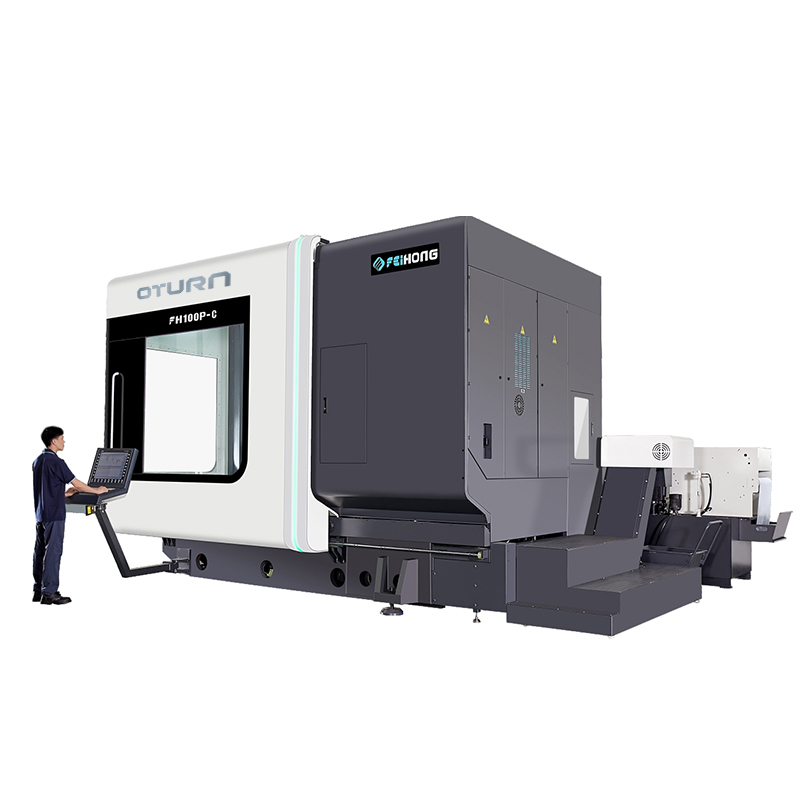

As we approach 2025, the manufacturing landscape is rapidly evolving, and the role of vertical turning center machines is becoming increasingly pivotal in optimizing production efficiency. These advanced machines are designed to handle a variety of machining processes, making them essential for various industries, including automotive, aerospace, and precision engineering. With their ability to process complex geometries and high-quality surfaces, vertical turning centers are redefining the standards of production and machining capabilities. The demand for vertical turning center machines is driven by the need for flexibility and precision in manufacturing. In a world where customization and rapid production cycles are paramount, these machines provide the ideal solution for manufacturers looking to enhance their competitiveness. Integrating advanced technology such as CNC controls and automation, modern vertical turning centers enable faster setup times, reduced cycle times, and improved part accuracy, ultimately leading to lower operational costs and higher return on investment. In 2025, prospective buyers can expect to see significant advancements in vertical turning center technology, including increased automation and connectivity as part of the Industry 4.0 revolution. These innovations will not only streamline operations but also facilitate remote monitoring and predictive maintenance, ensuring maximum uptime and productivity. For global buyers, investing in state-of-the-art vertical turning centers will be crucial in maintaining a competitive edge in an increasingly demanding market.

Vertical Turning Center Machine Factory in 2025

| Model | Max Swing (mm) | Max Turning Diameter (mm) | Spindle Power (kW) | Control System | Weight (kg) |

|---|---|---|---|---|---|

| VTC-2025 | 500 | 300 | 15 | CNC | 2500 |

| VTC-2520 | 600 | 350 | 18 | CNC | 2800 |

| VTC-3040 | 800 | 450 | 22 | CNC | 3500 |

| VTC-4040 | 1000 | 600 | 30 | CNC | 4500 |

Related Products