What is a CNC drilling and milling machine:

CNC drilling machines belong to metal cutting machine tools, with the functions of hole processing, drilling, tapping, boring and auxiliary milling. It is mainly used for high-efficiency drilling of flat plates, flanges, discs, rings, and other workpieces whose thickness is within the effective range.

Drilling through holes and blind holes can be realized on single material parts and composite materials. The machining process of the machine tool is digitally controlled, and the operation is very convenient. It can realize automation, high precision, multiple varieties, and mass production.

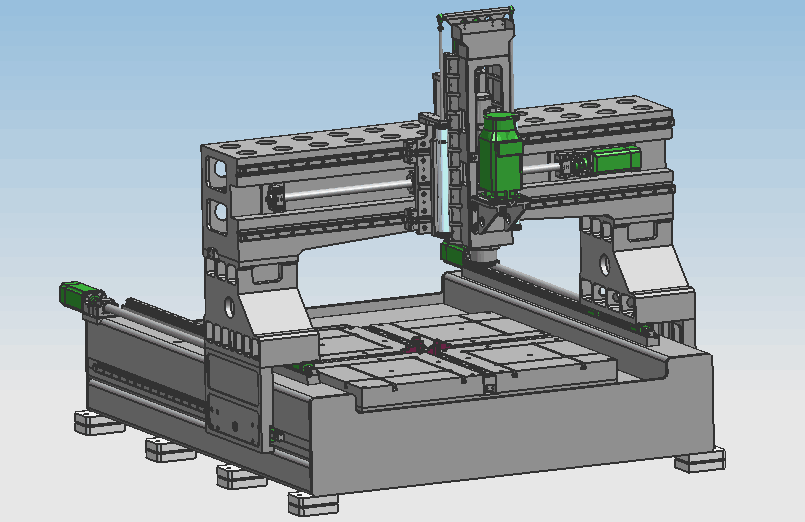

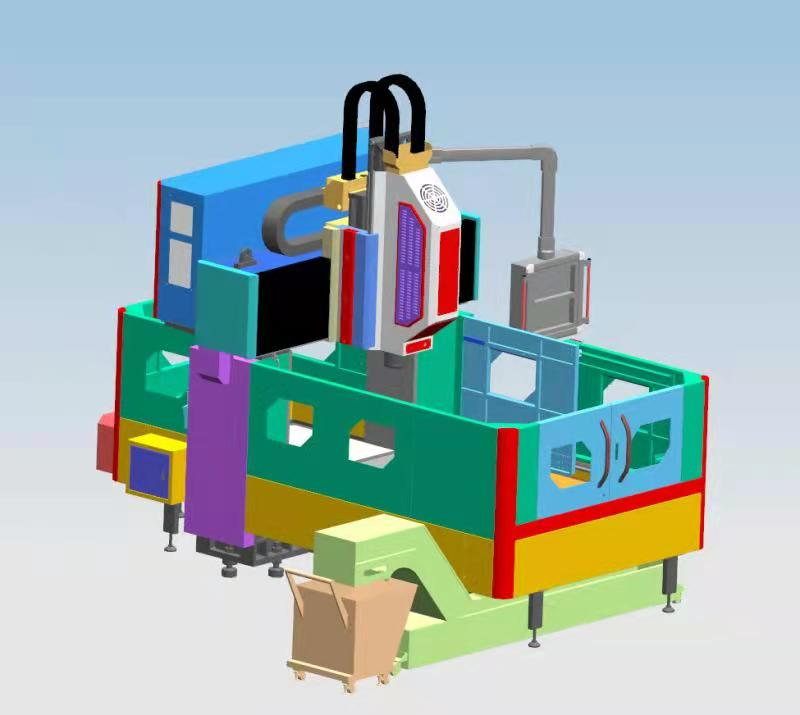

CNC drilling and milling machine equipment structure

1.Bed:

The bed is an integral structural part, finished by secondary annealing treatment, with good dynamic and static rigidity and no deformation. The working table adopts a casting structure, and there is a T-slot with a reasonable finishing layout on the plane, which is used to clamp the workpiece. The drive system adopts AC servo motor and precision ball screw pair to drive on both sides to make the gantry move in the X-axis direction. Adjustable bolts are distributed on the bottom surface of the bed, which can easily adjust the level of the worktable of the bed.

2. Mobile type gantry:

The movable gantry is cast and processed by gray iron (HT250), and a pair of rolling linear guides with ultra-high capacity is installed on the front side of the gantry. The precision ball screw pair and servo motor make the powerhead slide move in the Y-axis direction, and the drilling powerhead is installed on the powerhead slide. The movement of the gantry is realized by the rotation of the ball screw driven by the servo motor through the precision coupling.

3. Moving sliding saddle:

The sliding saddle is a precision cast iron structure. The sliding saddle is equipped with two ultra-high load-bearing CNC guide rail slides, a set of precision ball screw pairs and a high-precision planetary reducer connected to the servo motor to drive the drilling power head Moving in the Z-axis direction can realize the power head fast forward, work forward, fast reverse, stop and other actions. It has the functions of automatic chip breaking, chip removal and pause.

4. Drilling power head

The drilling power head adopts a dedicated servo spindle motor, which is driven by a toothed synchronous belt deceleration to increase torque to drive a dedicated precision spindle. The spindle adopts the front four and the rear two six rows of Japanese angular contact bearings to achieve stepless speed change. The spindle is equipped with a pneumatic tool change system to make the tool The replacement is quick and easy, and the feed is driven by a servo motor and a ball screw. The X, Y, and Z axes can be linked and adopt semi-closed loop control to realize linear and circular interpolation functions.

Drill Machine advantage

1.Water out of the spindle:

It adopts Taiwan's Jianchun brand water outlet spindle and high-power servo spindle motor to drive the spindle through geared synchronous belt deceleration to increase torque. Can use high-speed U drill (violent drill) and core drill bit center water processing.

2. Clamper

The X and Y axes are equipped with high-performance functional components used in conjunction with a clamper and a rolling linear guide pair. Using the principle of wedge blocks, it has the functions of fixing the gantry, precise positioning, preventing vibration and improving rigidity. The structure is compact and powerful.

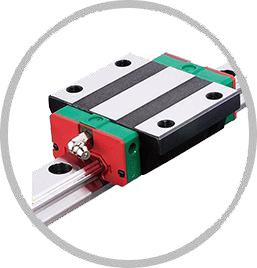

3. Linear guide and ball screw

It adopts Taiwan's Shangyin brand linear guide rail and TBI brand ball screw. The guide rails on both sides of the machine bed are installed vertically and parallel, and the force is even, ensuring stable machining and running of the machine.

4. Power head balance cylinder

There are two balance cylinders above the power head to balance the weight of the machine head. During the processing, the machine head is more stable, the smoothness of the hole is improved, and the wear on the Z-axis screw is reduced.

5. Chip removal system

There is a chain plate chip conveyor at the back of the machine tool. Use with a high-pressure water gun to quickly flush iron filings into the chip conveyor, which conveys the iron filings, saving time for manual cleaning of iron filings and reducing labor. The chip conveyor is equipped with a liquid level alarm lamp, which automatically alarms when the cutting fluid is insufficient.

Model recommendation

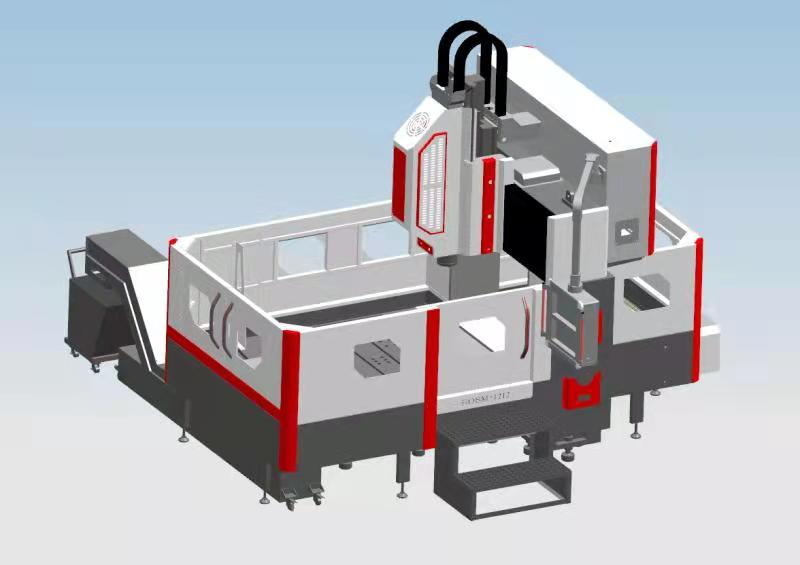

BOSM1600*1600 Self-centering CNC drilling and milling machine

BOSM1600*1600 type high-speed gantry CNC drilling and milling machine has an effective processing stroke of 1600*1600, which is cost-effective equipment. The machine has a four-jaw self-centering worktable, which makes it easier and faster to clamp ring workpieces. The maximum drilling is 50, It can use high-speed internal water outlet drilling, milling planes, milling grooves, and other processing. The equipment can be equipped with a tool magazine to realize multiple processes in one clamping.

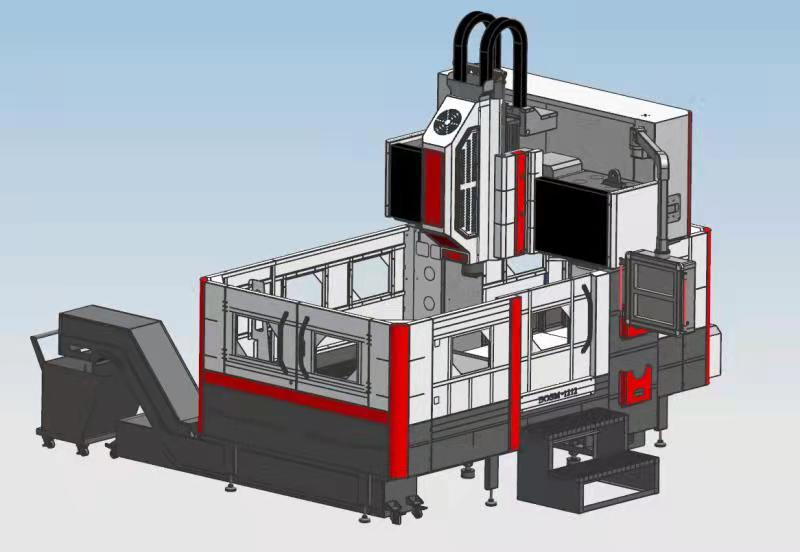

BOSM2500*2500 Self-centering CNC drilling and milling machine

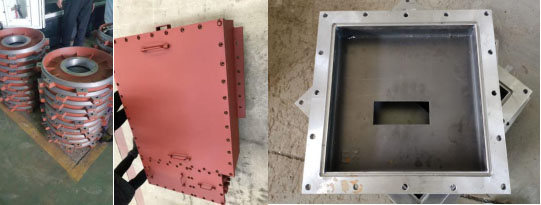

BOSM-2525 The split-type full-cast gantry type CNC high-speed drilling machine series are mainly used for high-efficiency drilling of large plates, wind power structural parts, discs, engineering machinery structural parts, valves, tube sheets and other workpieces within the effective range. Milling. Drilling through holes and blind holes can be realized on single material parts and composite materials. The machining process of the machine tool is digitally controlled, and the operation is very convenient. In addition to conventional models, they can also be designed and customized according to the actual needs of users.

CNC automatic drilling machine are currently widely used in the valve industry, flange industry, explosion-proof electrical industry, wind power industry, textile machinery industry, construction machinery industry, machining industry, automotive industry, etc.

For customers who are processing round products such as flanges, rings, slewing supports, tube sheets, etc., the outer diameter is less than 2.2m, the index circle is within 2m in diameter, and the aperture is within 50mm. The pain point for customers of this type of product lies in the clamping time More than the processing time, traditional processing equipment, such as CNC gantry milling or radial drill, use the clamp to clamp the material after loading, and then use the edge finder or use the professional tool to test the table to find the center, which consumes time and efficiency.

The BOSM drill machine is designed with a fixed worktable and a moving gantry. It adopts a self-developed large-travel four-jaw self-centering chuck, which solves the problem of small hydraulic or pneumatic jaws on the market. Large workpieces will hit the jaws when hoisting In the case of damage to the chuck, the workbench is provided with a strip-shaped structure pad, and the clamping is automatically centered at one time, which solves the problem of time-consuming clamping.

The four jaws on the workbench adopt a detachable style. After disassembly, the workbench is still a conventional platform with T-slots, which improves its application range for machining other workpieces outside of the circle. BOSM drill CNC machine is equipped with a guide rail clamp, 0.06 seconds extremely high opening and closing response time, which improves the machining accuracy and clamping force, and solves the previous problem of spindle vibration and tool life. Z-axis double-balanced cylinder, drag chain oil and gas separated from electricity, stable and rigid structure, electrical cabinet beam is behind for easy transportation, system boom style is easy to operate, anchor bolts can be used after landing and leveling.

BOSM automatic drilling machine has improved and upgraded the head part of the column beam. After the column is changed, the waterproof sheet metal is greatly improved, the waterproof effect is more ideal, and the appearance design can be more beautified.

BOSM cnc drilling machine manufacturing is equipped with a central water filtration system, and the water pressure is relatively high. The structure of the rear cutting machine of this model is not easy to clean up the iron cutting at the front. It is equipped with a car washing water gun to wash the iron cutting backwards.

Valve industry

Flange industry

Explosion-proof electrical industry

Wind power industry

Textile machinery industry

Machining industry

Construction machinery industry

Automotive industry

The BOSM factory is still constantly integrating the market and developing new models to minimize production and manufacturing costs. It has a wider range of processing functions, combined with drilling experience, and optimized milling functions. For example, the BOSM-DPH1212 fixed beam gantry milling we have developed and designed at present. For those who need to drill and mill with a processing width of 1200mm or less, an economical gantry drilling and milling machine that cannot be processed beyond the width of the VMC850 machining center on the market can realize customers' milling-based processing. Models in terms of processes.

The BOSM-DPH1212 model can realize fast hoisting and transportation, the width can be loaded into the container, and it can be quickly set down and used at the customer's place. Defined as an all-round drilling and milling machining center model, it is necessary to ensure the accuracy and rigidity of the machine tool. The three-axis guide will use Taiwan brand roller guides, grinding screws, and the worktable for grinding machine finishing to ensure machine tool performance.

BOSM-DPH1212 fixed beam gantry milling strives for the market where the width of the machining center cannot be solved, and the processing products are wasteful with large gantry milling. For example, the 1m CNC gantry machining center on the market, we are targeting a large number of CNC drilling, milling, and boring. The market demand for machining, there is also a market that solves the problem of rough machining of mold-type engraving and milling electromechanical spindles.

Post time: Sep-20-2021