Shaft Turning Machine Manufacturer in China: Quality & Precision

When it comes to precision and efficiency in machining, the Shaft Turning Machine stands out as a top choice for manufacturers like us in China. I’ve seen firsthand how this equipment transforms raw materials into finely crafted components, ensuring high-quality results every time. Whether you’re working on small batches or large-scale production, our machines offer user-friendly controls and robust performance to meet diverse manufacturing needs. As a manufacturer committed to excellence, we take pride in delivering machines that not only enhance productivity but also optimize resource usage. The Shaft Turning Machine is designed to handle various shaft sizes and materials, making it an invaluable asset for any workshop. Let’s connect to discuss how this machine can elevate your production capabilities and drive your business forward. It’s time to invest in equipment that delivers reliability and precision, tailored to the demands of today's industrial landscape.

Shaft Turning Machine Products From Concept to Delivery

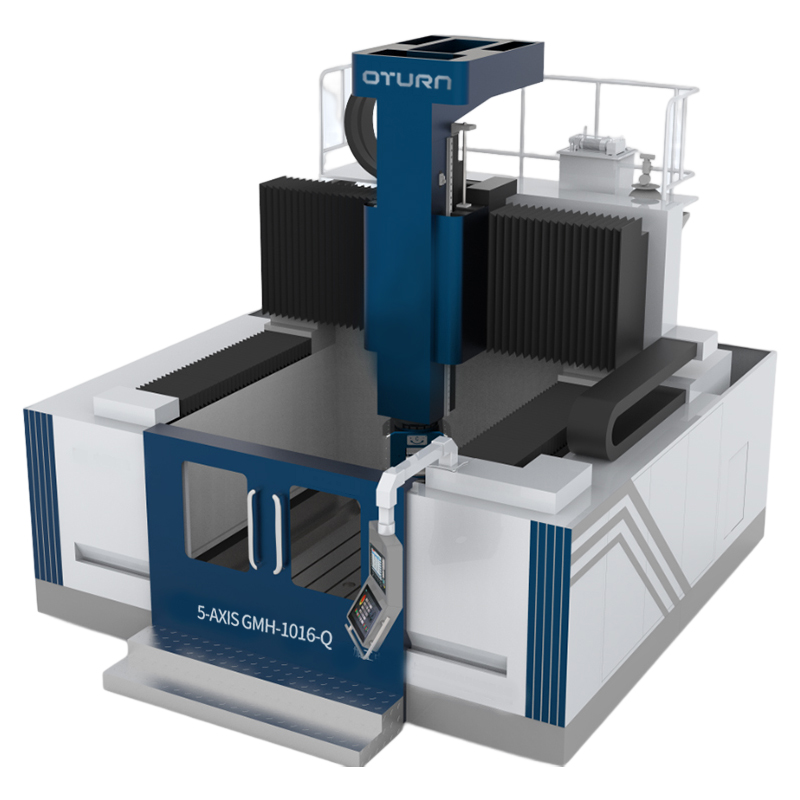

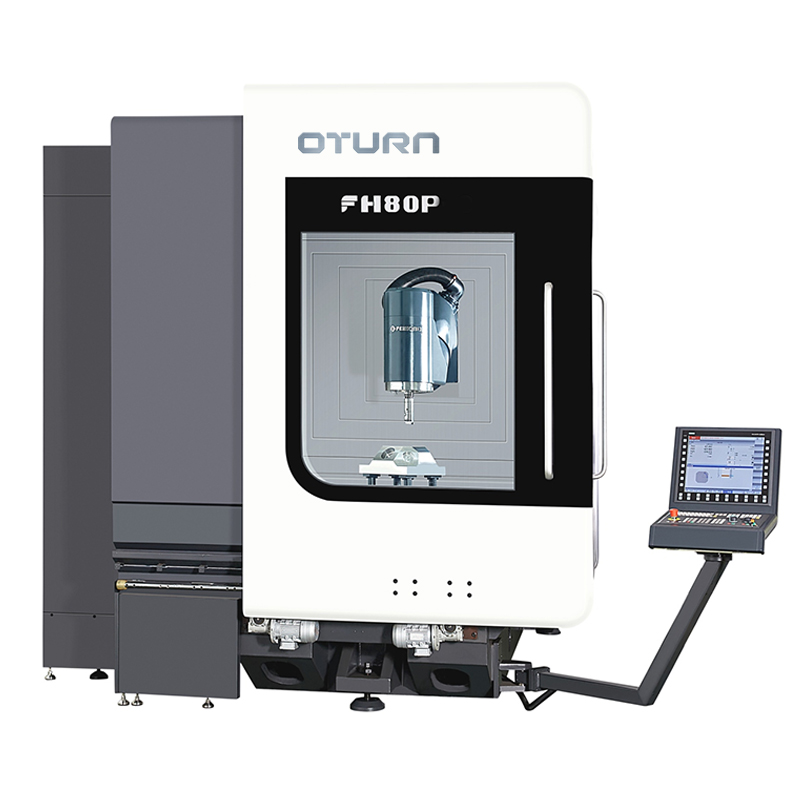

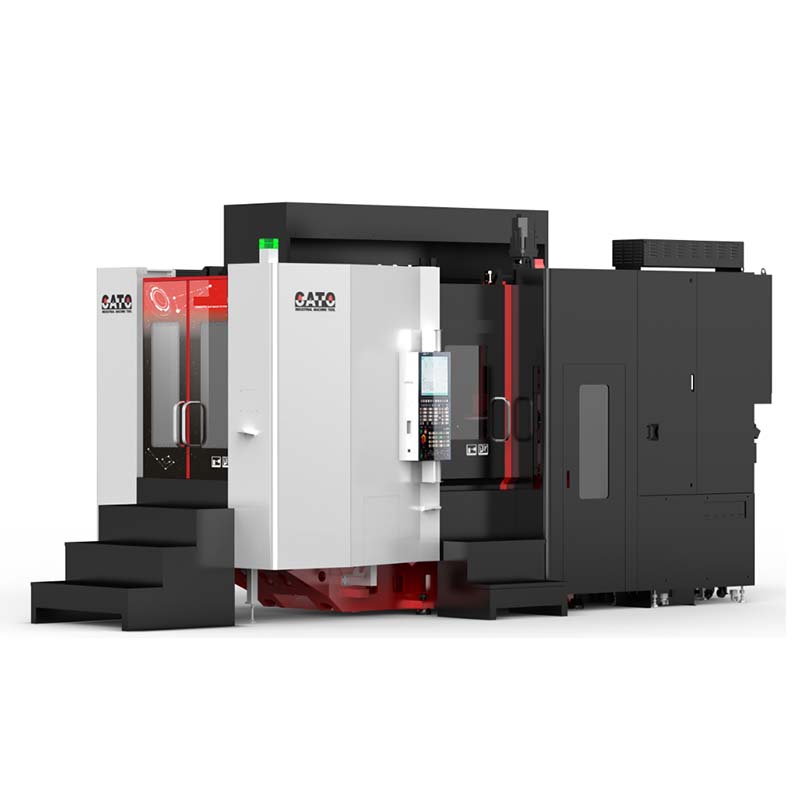

In the realm of precision engineering, the journey of a shaft turning machine from concept to delivery plays a critical role in the manufacturing process. These machines are designed to enhance efficiency, accuracy, and productivity, ensuring that businesses can meet the demands of modern production environments. From the initial design phase, where innovative ideas are transformed into detailed specifications, to the rigorous testing and quality assurance stages, every step is meticulously crafted to meet the highest industry standards. One of the key aspects in developing shaft turning machines is the integration of cutting-edge technology. Advanced CNC systems enable precise control over the machining process, while automation features minimize human error, resulting in consistent and reliable outputs. Additionally, collaborative efforts with engineers and designers ensure that the machines are tailored to meet specific operational needs, optimizing performance for various industries. Ultimately, the timely delivery of these machines is just as important as their design and functionality. Navigating the complexities of global supply chains, manufacturers ensure that each machine reaches its destination efficiently, ready to empower businesses around the world. By focusing on both innovation and reliability, companies can provide solutions that not only meet current demands but also anticipate future challenges in manufacturing.

Shaft Turning Machine Products From Concept to Delivery

| Product Model | Description | Material | Dimensions (mm) | Weight (kg) | Lead Time (weeks) |

|---|---|---|---|---|---|

| STM-100 | High precision shaft turning machine designed for large components. | Steel | 3000 x 800 x 1400 | 1500 | 4 |

| STM-200 | Versatile turning machine for medium-sized shafts with automation options. | Aluminum | 2500 x 600 x 1200 | 900 | 6 |

| STM-300 | Compact design ideal for small to medium shaft turning applications. | Cast Iron | 1500 x 500 x 1000 | 500 | 3 |

| STM-400 | Industrial-grade turning machine with CNC capabilities for high precision. | Alloy Steel | 4000 x 1000 x 1500 | 2000 | 5 |

Related Products