These seven applications are unequivocally essential for achieving success in automotive parts manufacturing. The precision and efficiency delivered by a Cnc Machining Center are foundational to modern automotive component quality and performance. A High-Precision CNC Machine ensures exceptional precision, restoring critical components to their original performance. It also offers reduced machining time, speeding up manufacturing while maintaining consistency. Industrial CNC Solutions, including the Horizontal Machining Center, help manufacturers meet stringent quality standards. This makes cnc machining center automotive applications vital.

Key Takeaways

- CNC machining makes car parts with great accuracy. This helps engines, transmissions, and other car systems work well.

- CNC machines build strong and safe parts for cars. This includes parts for the car’s body and brakes.

- CNC machining is very important for making electric car parts. It helps create battery cases and motor parts.

- CNC machining helps car companies make new designs faster. It also makes special car parts in small numbers.

- CNC machining helps car makers save money and time. It also makes sure all car parts are of high quality.

Cnc Machining Center for Engine Block and Cylinder Head Precision

Achieving High-Precision Bore and Surface Finishing

Engine blocks and cylinder heads demand extreme precision. A Cnc Machining Center delivers this accuracy for bore and surface finishing. For instance, these machines automatically spot face lifter bores. They also machine lifter bores to exact diameters, locations, and angles in one setup. This allows for truing stock sizes or boring new dimensions. Operators can use integrated conversational software. This software uses a conversational format, so operators do not need G-code knowledge. They can save and reuse programs easily. The machines perform block decking operations. This ensures a flat surface for gasket seals and proper deck height. It focuses on a 45-degree deck angle and accuracy. Boring operations enlarge cylinder bores for larger pistons. They also clean cylinder walls. Honing then follows for a smooth finish and accurate piston ring seal. CNC blueprinting uses a digitizing probe. It automatically measures cylinder bores, deck heights, and lifter bores. It compares these to factory specifications for precise adjustments. Multi-axis CNC machines can operate on up to seven axes. This allows comprehensive block work. The block can rotate in relation to the tooling head. Automatic tool changers also boost efficiency with rapid tool changes.

Crafting Complex Port and Valve Seat Geometries

Cnc Machining Centers also excel at crafting complex port and valve seat geometries. This is vital for engine performance. Five-axis CNC milling is a key technology. It enables high-precision complex geometries, reduces production errors, and offers faster turnaround. Multi-spindle turning and adaptive cutting also contribute to these benefits. These machines ensure perfect alignment for valve seats, guaranteeing proper sealing during combustion. A high-precision surface finish leads to better sealing. Optimized valve angles increase power output. CNC machines accurately reshape ports and chambers for aftermarket modifications and performance tuning. They also reproduce complex chamber geometries with precision, influencing flame propagation and engine efficiency. Perfectly balanced ports and chambers support high RPM applications. They reduce turbulence for smoother high-speed operation. CNC machines are crucial for replicating painstakingly designed port shapes with high precision and consistency. After design and prototyping, ports are digitized. Then, CNC machines cut the heads. This process allows for precise replication of complex port designs, impossible by hand. It ensures consistency and enables high-performance at a fraction of the cost.

Cnc Machining Center in Transmission Component Production

Ensuring Gear and Shaft Machining Accuracy

Automotive transmissions rely on incredibly precise gears and shafts. A Cnc Machining Center plays a crucial role in achieving this accuracy. Manufacturers must maintain tight tolerances and ensure correct backlash for gears to mesh perfectly. This prevents noise and wear.

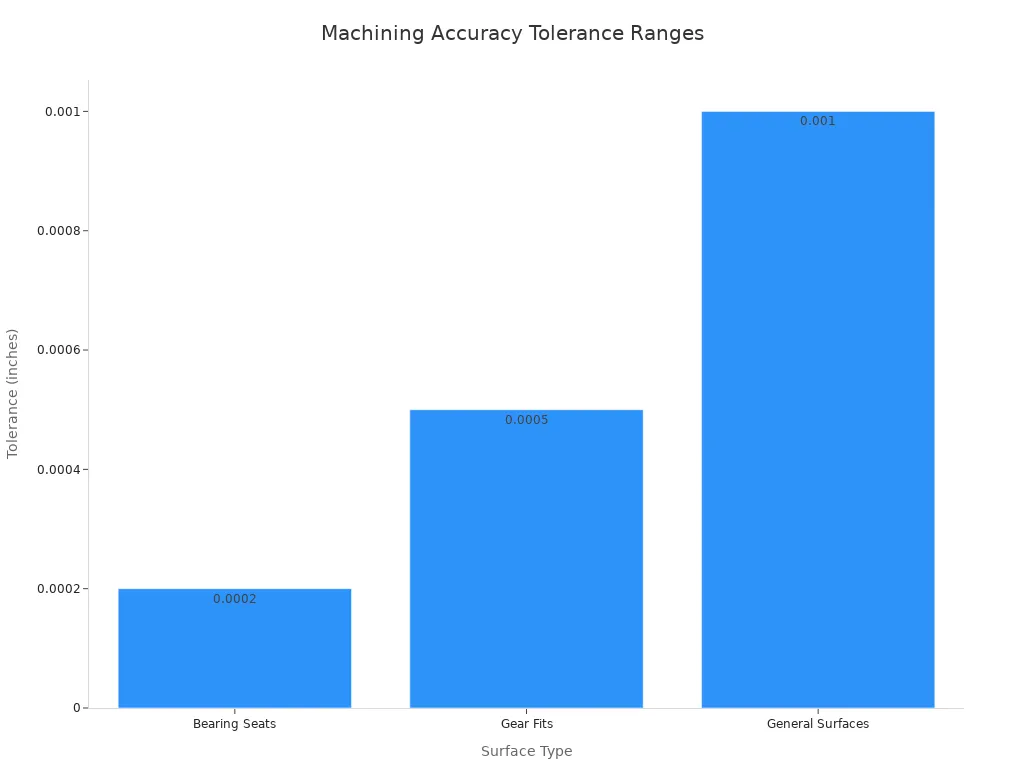

| Surface Type | Tolerance Range (inches) |

|---|---|

| Bearing Seats | ±0.0002 |

| Gear Fits | ±0.0005 |

| General Surfaces | ±0001 |

Consider these geometric tolerances: total runout typically falls between 0.001 and 0.003 inches. Cylindricity needs to be 0.0005 to 0.001 inches. Perpendicularity ranges from 0.001 to 0.002 inches. Surface finish also matters greatly. Bearing surfaces require 16-32 μin Ra, while gear fit areas need 32-63 μin Ra. General surfaces usually require 63-125 μin Ra. Experts expect future car transmissions to improve by one or two accuracy grades. This means tolerances will reduce by half to make transmissions quieter.

Mastering Valve Body and Casing Intricacy

Valve bodies and casings in transmissions are complex parts. They have many internal channels and ports. CNC machining processes are essential for creating these intricate components.

- Rough Turning/Milling: This step removes extra material from the outside and faces. For a 2-inch gate valve body, the spindle speed is often 800–1200 RPM. The feed rate is 0.2–0.4 mm/rev, and the depth of cut is 2–3 mm.

- Drilling and Boring: These operations create internal cavities and ports. For a 316 SS valve body, carbide drills work at 50–70 m/min cutting speed. The feed rate is 0.1–0.15 mm/rev. Coolant helps prevent hardening. For bonnets, central bores and bolt holes are machined with a ±0.015 mm positional accuracy.

- Threading: This creates threaded ports for connections. NPT threads need a 1°47′ taper angle. A thread mill works at 30–50 m/min cutting speed. For bonnets, threads for body connection use a 40–60 m/min cutting speed.

- Finish Milling/Surface Milling: This step achieves specific surface roughness for flange and sealing faces. For valve bodies, a face mill achieves Ra 0.8–1.6 µm. It uses a 0.05–0.1 mm/tooth feed rate and 100–150 m/min cutting speed. For bonnets, a face mill achieves Ra 1.6 µm with the same feed rate.

Manufacturers use rigid fixturing to reduce vibration. They also monitor tool wear. In-process inspections, like CMM for critical dimensions, ensure quality.

Cnc Machining Center for Chassis and Suspension Part Fabrication

Precision in Steering Knuckle and Control Arm Manufacturing

Chassis system parts, like suspension walls and subframes, require significant mechanical strength and machining stability. Vertical Machining Centers provide structural stability through high dynamic rigidity and efficient turning capabilities for these components. Steering knuckles and control arms are critical for vehicle handling and safety. Manufacturers traditionally made steering knuckles from ductile cast iron or forged steel. However, the demand for lightweight components now favors aluminum knuckles. A Cnc Machining Center processes these materials efficiently, often in one or two setups. Tool suppliers offer customized tools that combine multiple operations. These include slot milling, boring, drilling, and reaming. This approach improves cycle time and optimizes tool magazine usage. Multi-axis CNC milling creates complex shapes with dimensional accuracy of ±0.050 mm. Precision boring ensures bearing housings have a bore tolerance of ±0.012 mm. Precision drilling achieves angle accuracy of ±0.05 degrees for ball joint tapers. Face milling also creates flat surfaces for brake caliper mounting with flatness of ±0.030 mm.

Machining Brake Caliper and Hub Components

Brake caliper and hub components must meet exact specifications and tolerances. They endure high stress, extreme heat, and significant mechanical loads. CNC machining provides high precision and repeatability for these parts. It creates perfectly cylindrical piston bores, precisely drilled mounting holes, and uniform outer surfaces. Milling shapes the caliper by removing excess material. Face milling creates flat surfaces. Slot milling cuts precise slots for brake pads. Contour milling produces complex shapes, ensuring precise alignment and structural integrity. Drilling and tapping create hydraulic ports, mounting holes, and ventilation features. Honing achieves a smooth finish on piston bores, ensuring optimal piston movement and enhanced sealing. Surface grinding creates high-precision flat surfaces on mounting faces. This reduces noise and vibration. Deburring removes sharp edges. Thermal treatment relieves residual stresses, preventing warping. Five-axis CNC machining creates complex caliper geometries with increased precision and faster production times. High-precision CNC machining ensures dimensional accuracy and surface finish for critical areas. Heat treatment enhances hardness and strength. Surface treatment improves corrosion resistance.

Cnc Machining Center in Powertrain and Drivetrain Manufacturing

Critical Crankshaft and Camshaft Machining

Powertrain components like crankshafts and camshafts demand extreme precision. A Cnc Machining Center ensures this accuracy for performance, efficiency, and reliability. These machines maintain tight tolerances. They perform critical operations such as turning, milling, drilling, and grinding. This contributes to improved crankshaft performance and durability. For example, finish grinding of crankshaft and camshaft bores guarantees coaxiality and roundness error of ≤0.005mm. This meets bearing assembly requirements.

The process begins with CNC programming and tool selection. This involves converting CAD geometry into machine instructions. It defines toolpaths, selects cutting tools, and establishes machining parameters. Next comes machine setup and workholding. This requires proper workpiece fixturing, mounting parts, probing reference surfaces, and measuring tool length and diameter offsets. Once initiated, CNC machining operations run automatically. Spindle motors rotate cutting tools, and servo motors drive linear axes at controlled speeds and feed rates. Secondary operations like deburring, threading, heat treatment, and surface finishing complete the process.

Producing Differential Housing and Axle Components

Differential housings and axle components require high strength and precise manufacturing. CNC machining processes are essential for producing these parts. Precision CNC milling creates complex internal cavities and mounting surfaces. Precision boring is essential for bearing assemblies, ensuring concentricity within 0.01mm. This prevents premature wear and noise, extending differential life by 40-60%. Deep hole drilling creates lubrication passages. Specialized surface treatments are applied for corrosion resistance and wear protection.

Accurate dimensional control, within ±0.125mm, ensures proper component fitment and gasket sealing. This prevents lubricant leaks and contamination. Optimized internal geometries control clearances. This improves lubrication flow, reducing operating temperatures by 10-15°C and extending gear life. A quality surface finish on gear contact areas reduces friction and wear. This extends service life beyond 200,000 miles. Manufacturers use materials like ductile iron for heavy-duty applications or aluminum alloys for lightweight designs. Cast steel is chosen for extreme load-bearing capacity. Gray cast iron offers a cost-effective option for standard applications.

Cnc Machining Center for Electric Vehicle (EV) Component Manufacturing

Fabricating Battery Casing and Tray Structures

Electric vehicles rely heavily on robust battery casings and tray structures. These components protect the battery pack and contribute to the vehicle’s overall safety and durability. Manufacturers use 5-axis CNC milling for battery module mounting surfaces and cooling system interfaces. This method achieves impressive accuracy, for example, ±0.005 inches on long extruded aluminum frame profiles. It also processes thick aluminum plate stock for cooling plates, holding channel tolerances of ±0.003 inches.

CNC drilling and tapping prepare aluminum frame sections. These operations create mounting holes, electrical feedthrough penetrations, and thermal management fitting holes. They provide positional accuracy of ±0.008 inches. For joining aluminum sections, friction stir welding is a common technique. It achieves 70-80% of the parent material’s strength without needing filler material. Laser welding creates hermetic seals on battery compartment covers, ensuring a tight, protective enclosure. For high-volume production of steel lower trays, progressive die stamping produces hundreds of parts per hour with excellent repeatability.

Machining Motor Housing and Stator Components

Precision is paramount for EV motor housing and stator components. These parts directly impact motor efficiency and performance. Manufacturers perform rough and finish machining on the outer geometry of motor housings. They also machine the inner surface and connection face, including various drilling and milling processes.

For rotor and stator components, precision turning, milling, and balanced finishing are essential. These processes support complex rotor geometries and lamination stacks. They maintain tight tolerances, often up to ±0.002 inches. For example, the outer diameter of rotors is machined to a tolerance of ±0.002 inches. This precisely controls the air gap. Stators receive machining to an inner diameter tolerance of ±0.002 inches for proper rotor alignment, ensuring a small clearance. Pocket dimensions for rotor magnets are machined to ±0.003 inches, securing their retention. The shaft diameter is machined to an even tighter ±0.0008 inches for a secure bearing fit. A concentricity tolerance of 0.001 inches is maintained between the rotor’s outer diameter and the shaft. These precise operations ensure the motor performs optimally.

Cnc Machining Center for Automotive Prototyping and Low-Volume Production

Rapid Iteration for New Automotive Designs

Automotive companies use rapid prototyping to quickly develop new designs. CNC machining is a vital technology for this process. It creates parts with tight tolerances, which is crucial for engine components. This method produces parts with complex shapes and high precision. It significantly reduces production time. Prototypes can be ready in days or hours. This allows for quicker design changes and faster testing. Engineers can quickly revise and re-test designs based on feedback. Components that once took weeks now get machined in just a few days. They can be tested and replaced with an improved version almost immediately. This speed helps identify design flaws, mechanical issues, or performance problems early. It prevents costly errors later on. CNC machining offers high precision, with tolerances as tight as ±0.001 inches. It works with many materials, including aluminum, and steel. Parts also have an excellent surface finish and strong structural integrity.

Manufacturing Specialized Automotive Components

Low-volume production is essential for specialized automotive components. CNC machining offers a cost-effective solution for short runs. High setup costs for large-scale production make it impractical for small batches. This method requires fewer machines, making it financially viable for new businesses. It ensures high precision and consistency. Each part meets exact specifications, which is critical for custom components. Manufacturers can quickly produce and test small batches. This allows for rapid design changes and faster market entry. Small batches also allow easy design modifications between runs without significant cost. Automotive companies can test various component shapes and fine-tune manufacturing processes. This approach aligns production with actual demand. It minimizes the need for large inventories and reduces financial risk. Businesses can adapt quickly to market changes. CNC machining is perfect for creating prototypes to test functionality. It also helps design before committing to mass production. It produces unique or limited-edition components for vintage cars, upgrades, and premium models. This ensures high precision and exact specifications.

Cnc Machining Center in Tooling, Fixture, and Mold Making for Automotive

Creating Die and Mold Cavities for Automotive Parts

Automotive manufacturing relies heavily on precise dies and molds. These tools shape everything from body panels to intricate interior components. Manufacturers use advanced techniques to create these critical parts. For example, ultrasonic processing technology integrates ultrasonic waves with machining. This improves efficiency, especially for brittle materials. It uses high-frequency vibration and power to achieve the desired mold shape. This method enhances accuracy and reduces damage. High-pressure water-cutting technology also plays a role. This advanced method uses water jets at supersonic speeds to cut mold material. It offers benefits like no heat-affected zone and minimal material loss. This makes it ideal for complex shapes and fine details.

Achieving high precision in mold making requires careful control. Spindle rotation control is crucial. The machine tool spindle’s rotation directly affects mold placement and positioning. Strict control over balance, alignment, and lubrication prevents precision loss. Processing strength and temperature control also significantly impact mold quality. Managing these factors prevents issues like mold deformation or fracture. This involves selecting suitable tools, optimizing cutting depth, and using cooling lubricants. These steps manage frictional frictional heat, especially at high temperatures, to maintain accuracy.

Producing Custom Fixtures and Jigs for Automotive Assembly

Custom fixtures and jigs are essential for efficient automotive assembly lines. They hold parts in place during various manufacturing stages. CNC machines, as part of automated systems, greatly improve the production speed and consistency of these tools. They operate continuously with minimal human intervention. This ensures a steady supply of high-quality fixtures.

Engineers use Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies with CNC machining. This allows them to create highly detailed and customized designs for automotive production lines. CAM then automates the manufacturing process. This ensures accurate and consistent production of each fixture. These cutting-edge manufacturing technologies enable more complex and accurate tooling solutions. They also increase design capabilities and reduce lead times and manufacturing costs. CNC machining produces robust jigs and fixtures for high-load environments. This makes them ideal for high-volume, durable, and large jigs and fixtures where long-term performance and precision are essential.

The Collective Impact of Cnc Machining Center Applications on Automotive Success

The widespread use of Cnc Machining Center applications fundamentally transforms automotive manufacturing. These technologies collectively drive innovation, boost efficiency, and guarantee top-tier quality. They are not just tools; they are essential partners in building the cars of today and tomorrow.

Driving Innovation and Performance in Automotive Design

CNC machining fuels innovation in automotive design. It allows engineers to create complex engine components like cylinder heads and suspension arms with optimal fit and function. This technology is crucial for powertrain and transmission systems, producing gears and shafts with precise dimensions for smooth shifting. For electric vehicles, CNC machining makes battery housings and motor components with exceptional accuracy. This maximizes battery life and improves vehicle performance. Designers also use CNC for rapid prototyping. They quickly create functional prototypes to test and refine new designs before full production. Multi-axis machining creates intricate designs previously impossible, using lightweight materials like aluminum and carbon fiber to enhance vehicle performance.

Enhancing Cost-Effectiveness and Manufacturing Efficiency

CNC machining significantly boosts cost-effectiveness and manufacturing efficiency. These machines operate continuously, maximizing productivity and reducing lead times. They streamline production by optimizing cutting paths and minimizing material waste. This leads to reduced costs and more sustainable practices. For example, precision multi-axis CNC machines can increase accurate production by 25% and cut component production time by 30%. They also reduce raw material waste by about 15%. Companies like Rolls Royce have seen a 30% faster production turnaround. Tesla improved production efficiency for complex components, and Ford lowered manufacturing costs for engine parts.

Ensuring Uncompromising Quality and Reliability Standards

CNC machining guarantees uncompromising quality and reliability in automotive manufacturing. It produces highly accurate, complex, and custom parts with pivotal precision. This technology helps manufacturers meet stringent quality standards for safety and performance. This is especially true for critical components like engine blocks and suspension systems. CNC manufacturing ensures parts are made with high precision, adhering to strict quality control standards. It uses inspection equipment like CMMs and hardness testers for rigorous checks. This process improves part quality by maintaining tight tolerances and minimizing errors. It provides repeatable precision, leading to consistent final products that meet the automotive industry’s strict safety and performance requirements.

These seven applications are truly essential for automotive manufacturing success. They are not just helpful; they are indispensable. Their ongoing development will shape future automotive advancements and competitive advantages. For example, smart CNC machining and automation will boost productivity and precision.

Embracing these technologies helps navigate current challenges and seize future opportunities. Manufacturers face high initial investment and a talent shortage. However, advanced materials and EV manufacturing demand these precise methods. They ensure quality and efficiency, even with complex parts.

FAQ

What is a CNC Machining Center?

A CNC Machining Center is a computer-controlled machine tool. It performs various machining operations like milling, drilling, and boring. These machines use pre-programmed instructions. They create complex parts with high precision and repeatability. This makes them essential for modern manufacturing.

Why is CNC machining important for automotive parts?

CNC machining provides extreme precision and efficiency. It ensures critical automotive components meet strict quality standards. This technology helps create complex geometries and tight tolerances. It improves vehicle performance, safety, and reliability. Manufacturers rely on it for consistent, high-quality production.

What types of automotive parts benefit most from CNC machining?

Many automotive parts benefit from CNC machining. These include engine blocks, cylinder heads, transmission components, and chassis parts. It also produces critical powertrain and drivetrain elements. For electric vehicles, it fabricates battery casings and motor components.

How does CNC machining help with EV components?

CNC machining is crucial for EV components. It precisely fabricates battery casings and tray structures. It also machines motor housings and stator components. This ensures optimal fit, thermal management, and electrical performance. It contributes significantly to EV efficiency and safety.

Can CNC machining be used for prototyping?

Yes, CNC machining is excellent for automotive prototyping. It allows rapid iteration of new designs. Engineers quickly create functional prototypes. They test and refine designs before mass production. This speeds up development and helps identify issues early.

Post time: Dec-08-2025