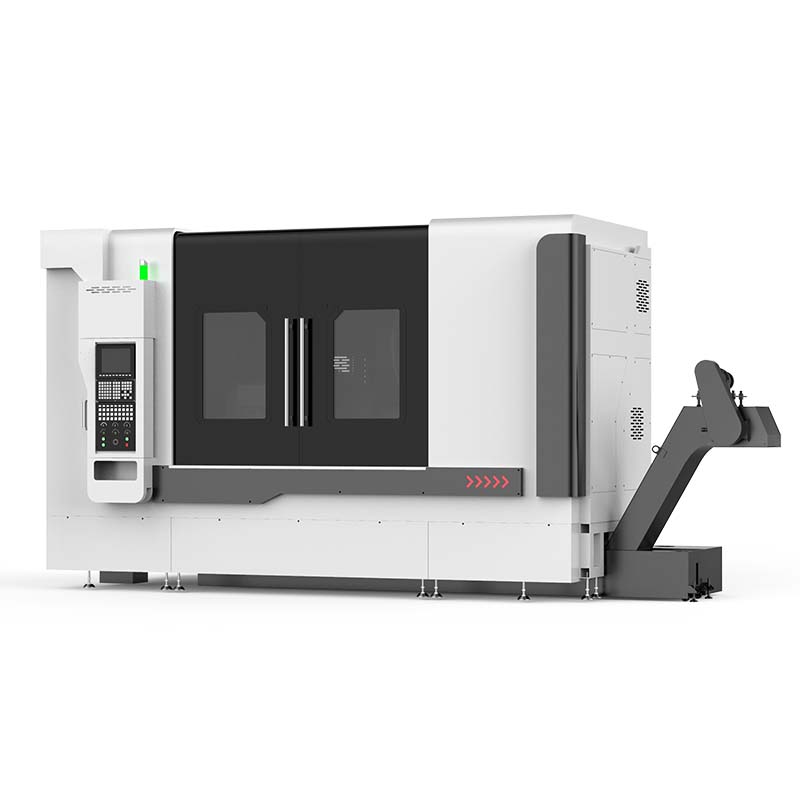

Top China Manufacturer of Metal Cutter Lasers for Precision Cutting

When I think about high-performance metal cutter lasers, I immediately consider the advantages of sourcing from a reliable China manufacturer. Our metal cutter lasers are designed with precision engineering to meet the needs of various industries, ensuring smooth cutting and enhanced efficiency. With our machines, I’ve experienced a significant reduction in production time and costs, making it a smart choice for any business looking to enhance their operations. The durable construction and advanced technology mean you’ll get consistent results, whether you’re cutting stainless steel or aluminum. Working with a trusted manufacturer from China not just guarantees quality but also provides competitive pricing that’s hard to beat. I always find that investing in our metal cutter lasers pays off quickly, allowing you to tackle more ambitious projects with ease. Ready to elevate your production capabilities? Let’s connect and explore how our solutions can work for you.

Metal Cutter Laser Ahead of the Curve Outperforms the Competition

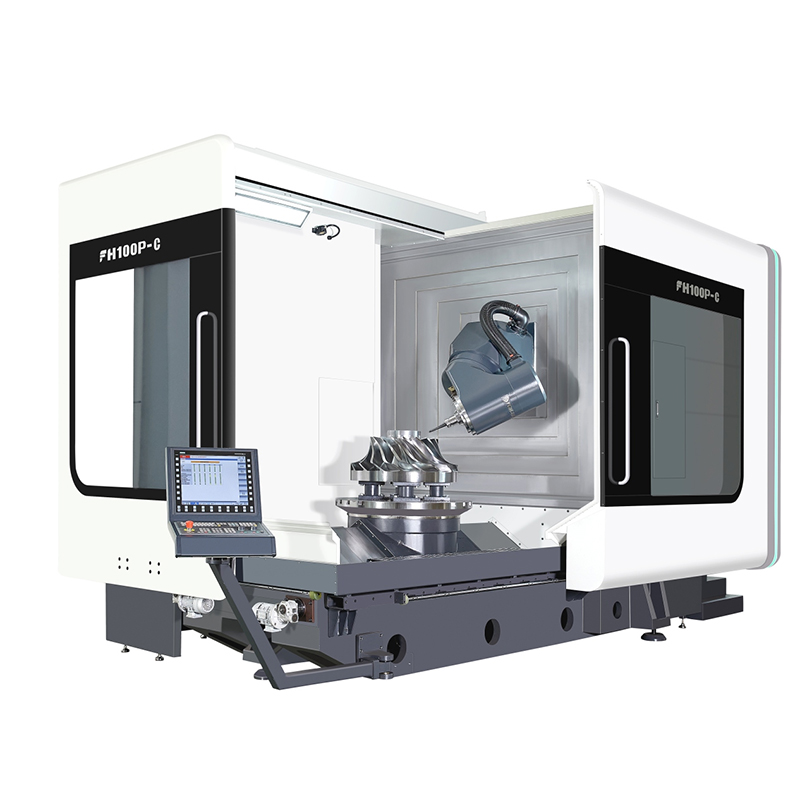

In the ever-evolving landscape of industrial machinery, staying ahead of the competition is essential for businesses aiming to enhance productivity and efficiency. Metal cutter lasers represent the forefront of innovation, combining precision engineering with cutting-edge technology. These advanced machines not only provide unparalleled accuracy in metal cutting but also optimize operational costs and time efficiency, setting a new standard in manufacturing. One of the key advantages of these state-of-the-art laser cutters is their ability to handle a diverse range of materials, from stainless steel to aluminum, with exceptional finesse. Unlike traditional cutting methods, laser technology minimizes waste and reduces the need for secondary processing, thereby streamlining the production process. Additionally, their user-friendly interfaces and automation capabilities allow for greater flexibility and ease of use, empowering operators to increase output without compromising on quality. As global demand for high-quality metal fabrication continues to rise, businesses seeking reliable and efficient solutions will find that investing in advanced laser cutting technology not only enhances their competitive edge but also drives long-term growth and sustainability. Embracing innovation in metal cutting is not just a choice; it is a necessity for thriving in today’s competitive market.

Metal Cutter Laser Ahead of the Curve Outperforms the Competition

| Feature | Performance Metric | Competitor A | Competitor B | Competitor C |

|---|---|---|---|---|

| Cutting Speed (m/min) | Average | 15 | 12 | 10 |

| Precision (µm) | Average | 50 | 70 | 80 |

| Material Compatibility | Types | Steel, Aluminum | Steel | Aluminum, Copper |

| Power Consumption (kW) | Average | 8 | 10 | 12 |

| Max Sheet Thickness (mm) | Capacity | 25 | 20 | 15 |

| Operating Cost ($/hour) | Cost Efficiency | 50 | 60 | 70 |

| Warranty Period (years) | Service | 5 | 3 | 2 |

Related Products