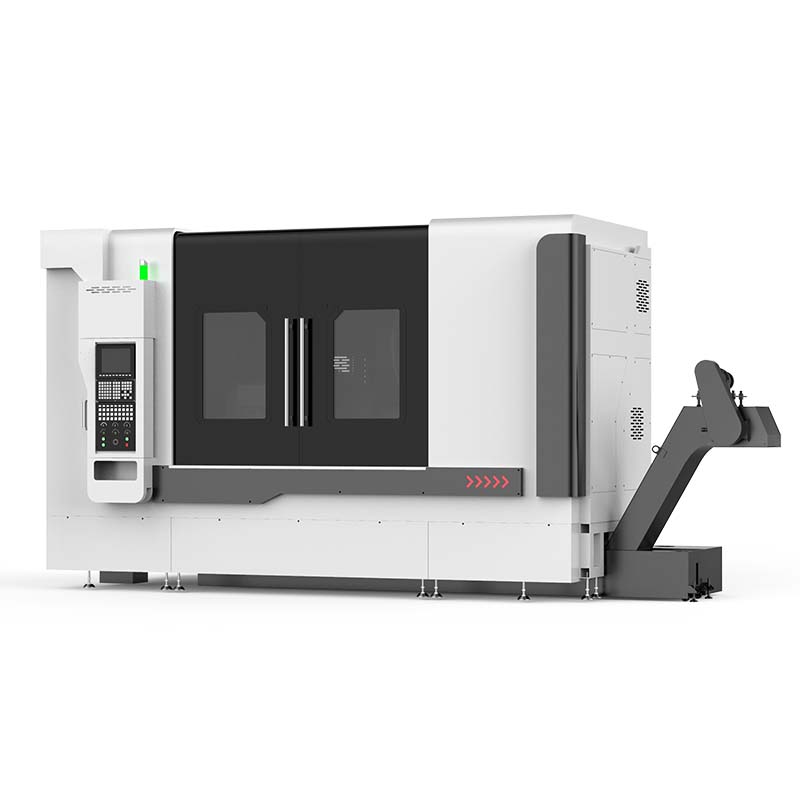

Lathe Machining Services by Leading Manufacturer in China

In the world of precision engineering, lathe machining stands out as a critical process, and I’m excited to share how our services can meet your manufacturing needs. Based in China, we specialize in providing high-quality lathe machining solutions tailored for a wide range of industries. Our state-of-the-art equipment and experienced technicians ensure that each project meets the exact specifications required. I understand the importance of reliability and precision when choosing a manufacturer. That’s why we prioritize quality control at every stage of production. From small batch runs to large-scale orders, our lathe machining capabilities can enhance your product's performance and durability. By partnering with us, you gain not just a manufacturer but a dedicated ally committed to your success. Let’s work together to bring your visions to life with expertly crafted components that stand the test of time.

Lathe Machining Factory More Than a Supplier - A Partner

In today's global market, the role of a lathe machining factory extends beyond merely being a supplier; it has evolved into becoming a trusted partner for businesses worldwide. With advances in technology and manufacturing processes, having a reliable partner in your supply chain can make all the difference. This partnership thrives on collaboration, efficiency, and a mutual understanding of demands, allowing companies to achieve their goals seamlessly. Choosing to work with a lathe machining factory that prioritizes partnership means benefiting from tailored solutions that cater specifically to your needs. These partnerships foster a closer relationship, ensuring that manufacturers not only understand the technical requirements of your projects but also share insights into industry trends and innovative practices. This enhanced collaboration results in improved products, optimized production processes, and ultimately, greater customer satisfaction. Furthermore, as businesses strive for efficiency, a partner within the manufacturing sector can help streamline operations through better communication and responsiveness. By working closely together, companies can nimbly respond to changing market demands, reduce lead times, and effectively manage risks. In today’s competitive landscape, these attributes can set a company apart as they seek to innovate and grow. Building a strong partnership with a lathe machining factory is an investment in quality and reliability that pays dividends in the long run.

Lathe Machining Factory More Than a Supplier - A Partner

| Service Type | Materials Used | Applications | Lead Time | Quality Certifications |

|---|---|---|---|---|

| CNC Lathe Machining | Aluminum, Steel, Brass | Automotive, Aerospace | 2-4 weeks | ISO 9001, ISO 14001 |

| Manual Lathe Machining | Plastic, Carbon Steel | Medical Devices, Industrial | 1-3 weeks | CE, AS9100 |

| Precision Machining | Titanium, Stainless Steel | Defense, Robotics | 3-6 weeks | ISO 13485, ITAR |

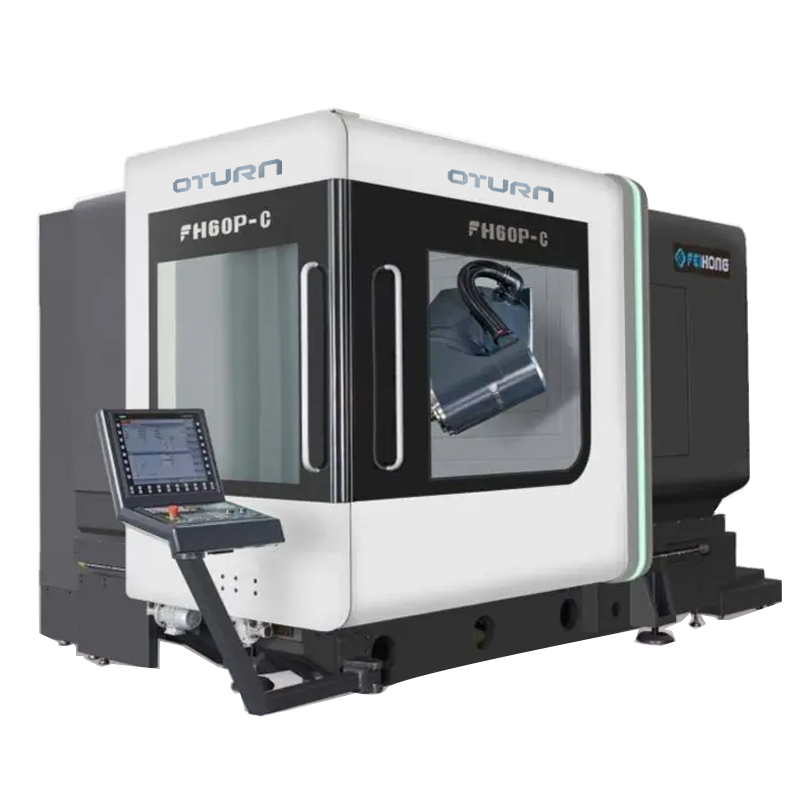

Related Products