Top China Manufacturer of Large Spindle Bore Lathes for Precision Machining

As a seasoned professional in the machining industry, I understand the importance of precision and efficiency. Our Large Spindle Bore Lathe, crafted in China by a reputable manufacturer, stands out for its exceptional capabilities. Designed to handle heavy-duty tasks, this lathe allows for larger diameters and longer workpieces, making it perfect for industrial applications. I've seen its impressive performance firsthand, as it seamlessly combines power and accuracy. The user-friendly interface ensures that operators can easily navigate and execute complex projects. With robust construction, this lathe not only enhances productivity but also guarantees longevity in demanding environments. Choosing our Large Spindle Bore Lathe means investing in quality and reliability. I'm confident that it will meet your manufacturing needs and propel your operations to new heights. Let's connect and take your machining capabilities to the next level together!

Large Spindle Bore Lathe Service Ahead of the Curve

In today’s competitive manufacturing landscape, large spindle bore lathes are increasingly recognized for their vital role in enhancing productivity and precision in machining processes. These robust machines offer the unique capability to handle large workpieces, making them essential for industries such as aerospace, automotive, and heavy machinery. With advancements in technology, modern lathes are not just about power; they incorporate sophisticated features that ensure higher efficiency, reduced cycle times, and increased flexibility. Investing in a large spindle bore lathe can provide significant advantages, including improved operational performance and the ability to undertake complex manufacturing tasks with ease. This allows businesses to tackle a wider range of projects, respond rapidly to market demands, and maintain a competitive edge. Furthermore, the integration of smart technology enables real-time monitoring and predictive maintenance, reducing downtime and prolonging machine life. As industries continue to evolve, having access to cutting-edge machinery is paramount for global procurement teams looking to source reliable and innovative solutions. To stay ahead of the curve, companies should prioritize collaboration with manufacturers committed to quality and innovation. This partnership not only facilitates access to state-of-the-art machinery but also provides invaluable insights into industry trends and best practices. As procurement decisions increasingly influence production efficiency and cost-effectiveness, understanding the capabilities of advanced lathes will empower businesses to make informed choices that support their growth objectives.

Large Spindle Bore Lathe Service Ahead of the Curve

| Service Type | Description | Features | Applications | Maintenance Schedule |

|---|---|---|---|---|

| Precision Alignment | Aligns the spindle for maximum accuracy. | High-precision measurement tools | Machining, Automotive | Every 6 months |

| Bearing Replacement | Replacement of worn spindle bearings. | High-quality bearings, professional installation | Heavy Machinery, CNC Operations | Annually |

| Lubrication Service | Ensures that all moving parts are properly lubricated. | High-performance lubricants | General machining | Quarterly |

| Electrical System Check | Testing and maintenance of electrical components. | Multimeter testing, wire inspections | CNC machines | Every 3 months |

| Overall Inspection | Comprehensive service covering all machine aspects. | Full machine diagnostics | All machining operations | Bi-annually |

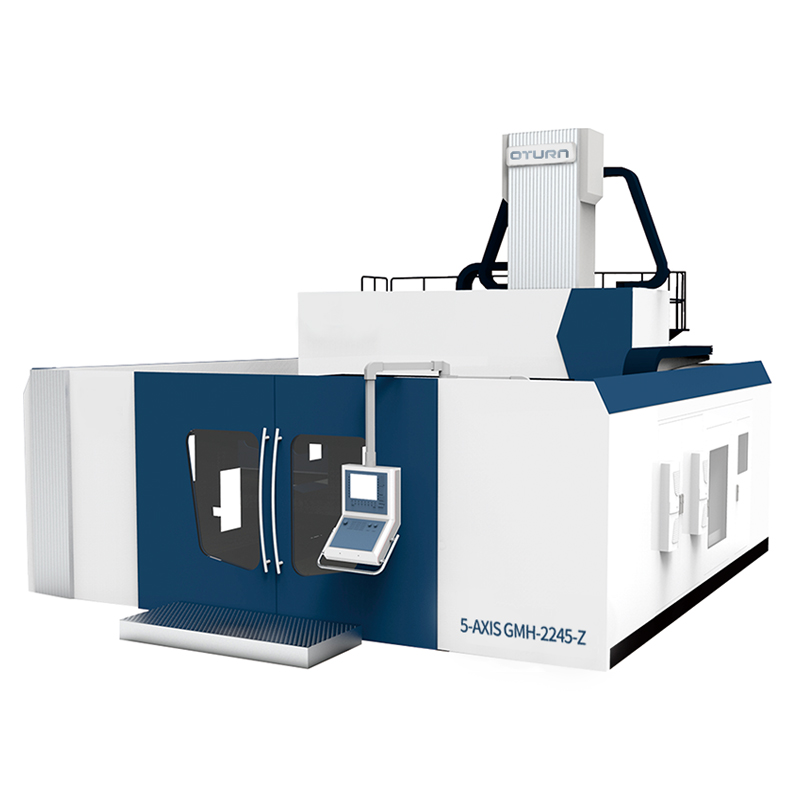

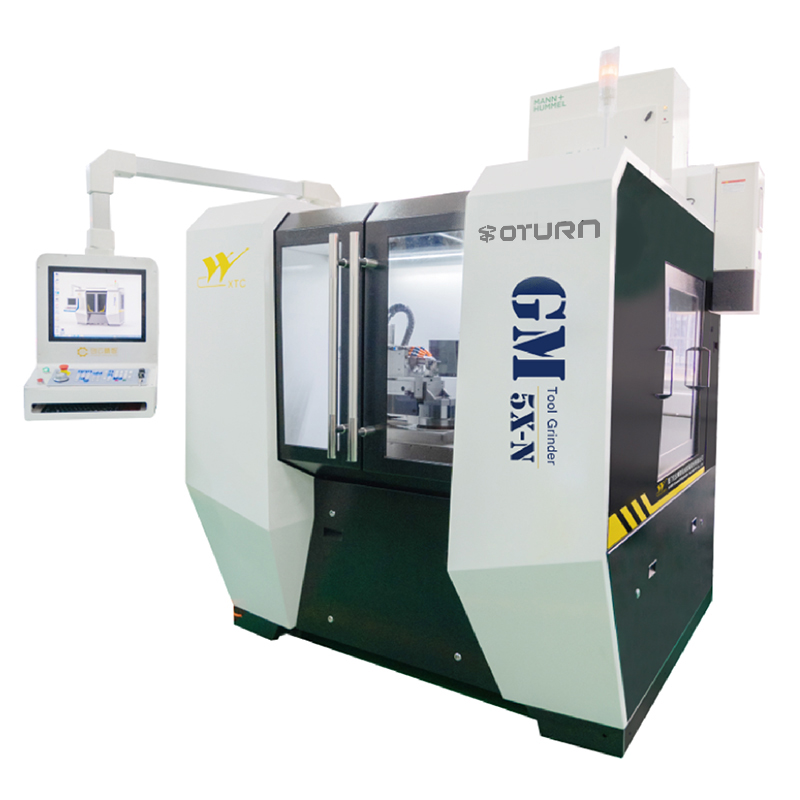

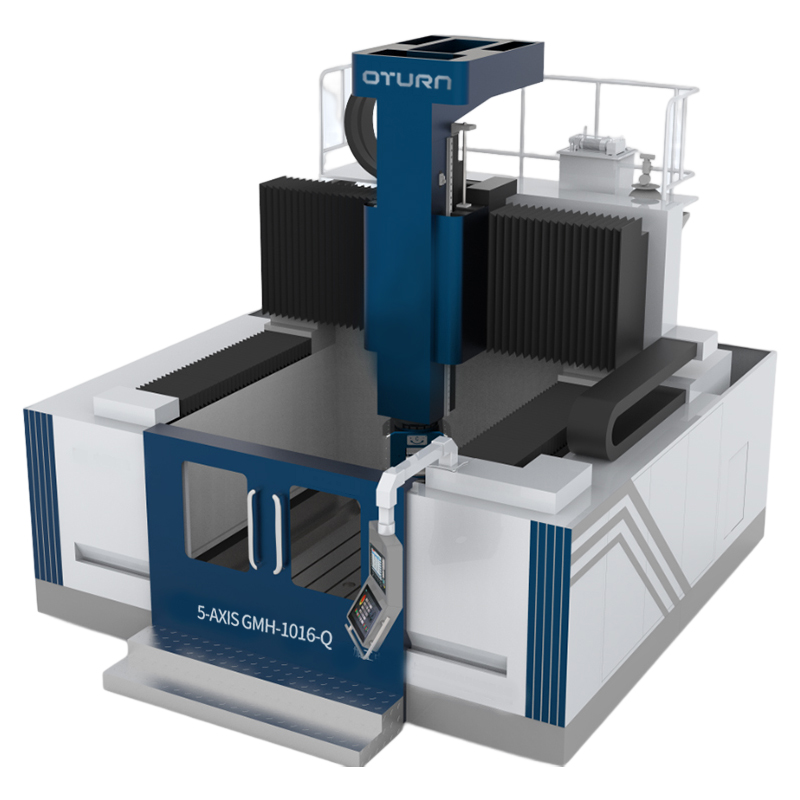

Related Products