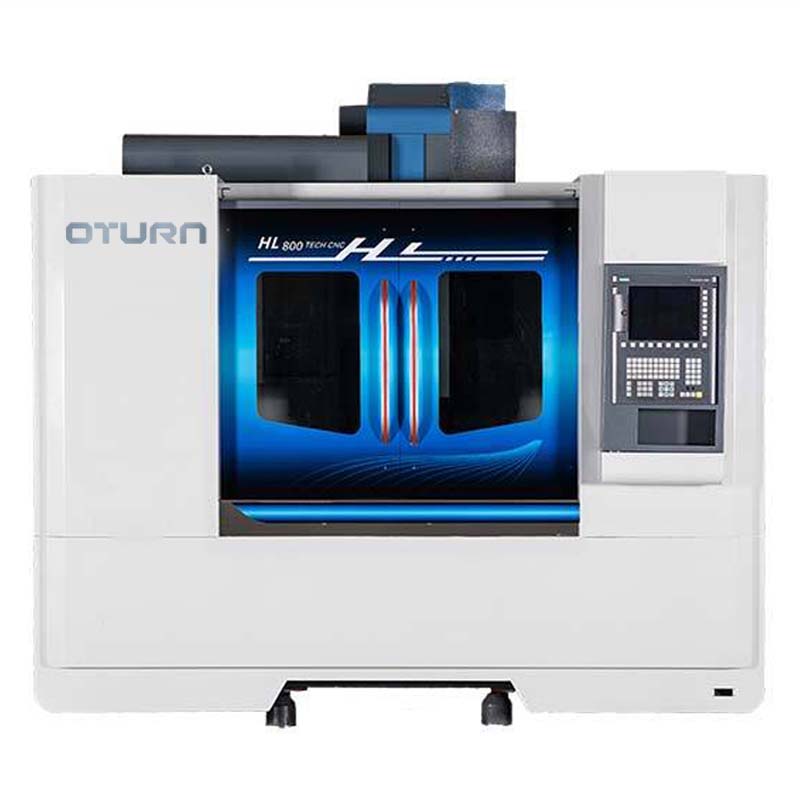

Quality Horizontal Lathe Manufacturers in China for Precision Engineering

When it comes to precision machining, I know that investing in a reliable horizontal lathe is key for your operations. Our horizontal lathes, manufactured in China, are designed to meet the rigorous demands of various industries, from automotive to aerospace. I’ve seen firsthand how these machines deliver exceptional accuracy and efficiency, improving production workflows and reducing downtime. Each lathe is built with high-quality materials and innovative features, ensuring long-lasting performance. I understand that as a B2B purchaser, you need machinery that not only fits your budget but also stands the test of time. That's why I can confidently say that our products offer excellent value. You won't just be buying a lathe; you'll be investing in a solution that elevates your manufacturing processes. Let’s connect and discuss how our horizontal lathes can help your business thrive!

Horizontal Lathe Products From Concept to Delivery

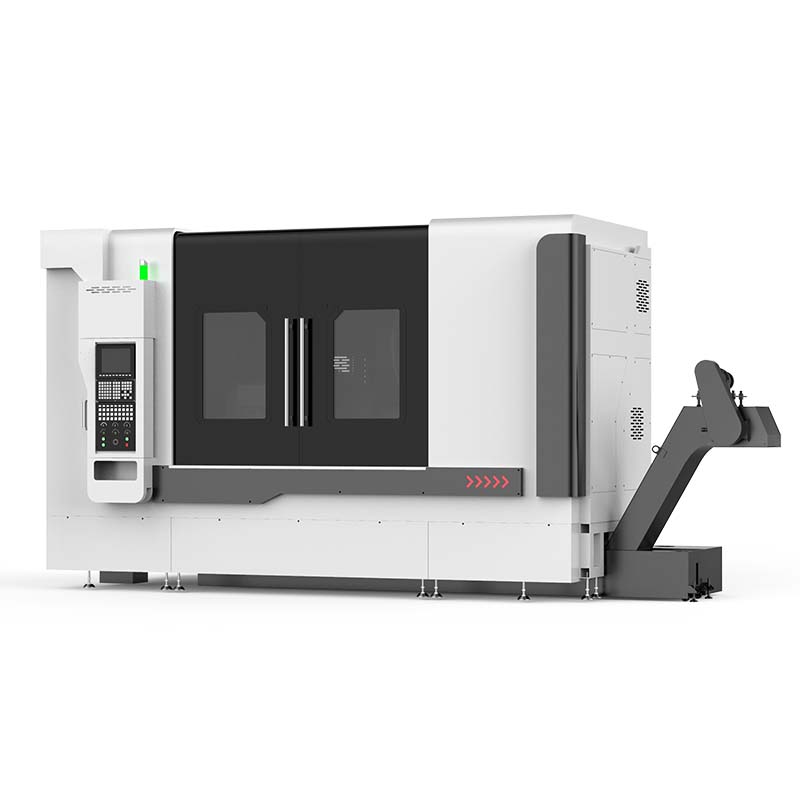

In today’s fast-paced manufacturing environment, the demand for high-quality horizontal lathe products has never been greater. As industries increasingly rely on precision machining for their operations, the process from concept to delivery must be seamless and efficient. Understanding this critical journey is essential for global buyers seeking to enhance their production capabilities. The journey begins with a clear concept, where client requirements and specifications are meticulously gathered to ensure that the final product aligns perfectly with their needs. Advanced design techniques, leveraging CAD (Computer-Aided Design) software, are employed to create prototypes that reflect the intended functionalities. Once the design stage is complete, cutting-edge manufacturing technologies come into play, utilizing state-of-the-art equipment and skilled technicians to fabricate components with utmost precision. Finally, the delivery phase is crucial, ensuring that products are shipped on time and in perfect condition. Effective logistics management and real-time tracking enable transparency throughout the shipping process, providing buyers with peace of mind. By prioritizing quality control and customer satisfaction at every stage, suppliers can foster long-term relationships with global procurement partners, ultimately driving mutual growth in the competitive landscape of precision machining.

Horizontal Lathe Products From Concept to Delivery

| Product Name | Specifications | Applications | Lead Time | Weight |

|---|---|---|---|---|

| Model A1 | CNC Control, Max RPM 3000 | Precision Machining | 4 Weeks | 500 kg |

| Model B2 | Manual Lathe, Max RPM 1500 | Small Batch Production | 6 Weeks | 300 kg |

| Model C3 | CNC, Max RPM 4000 | High Volume Production | 3 Weeks | 700 kg |

| Model D4 | CNC, Max RPM 3500 | Automotive Parts | 5 Weeks | 600 kg |

| Model E5 | High-Speed CNC, Max RPM 5000 | Aerospace Applications | 2 Weeks | 800 kg |

Related Products