Double Chuck Lathe Manufacturers in China: Precision and Quality

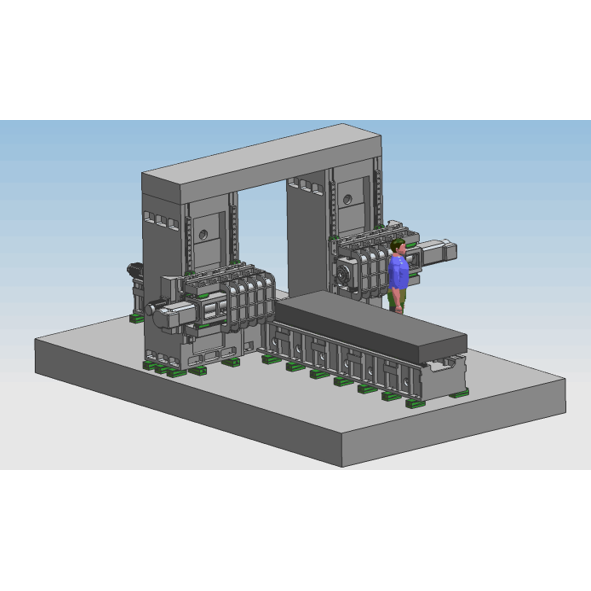

When it comes to precision and reliability, our Double Chuck Lathe stands out in the market. Manufactured in China, this robust equipment is designed for efficiency in both small and large-scale production. I know how crucial it is for you to find machinery that not only meets your specifications but also enhances productivity. That’s why our lathe is crafted with top-notch materials and advanced technology, ensuring you get the best results every time. With its dual chuck system, I can assure you that setups are quicker and changes are easier, minimizing downtime and maximizing output. Whether you're dealing with steel, aluminum, or other materials, this lathe provides the versatility you need to tackle varied projects. Our partnership with leading manufacturers in China means higher quality at competitive prices. If you’re looking for the perfect solution to your machining needs, I believe our Double Chuck Lathe will exceed your expectations and drive your business forward.

Double Chuck Lathe For the Current Year Manufacturers You Can Rely On

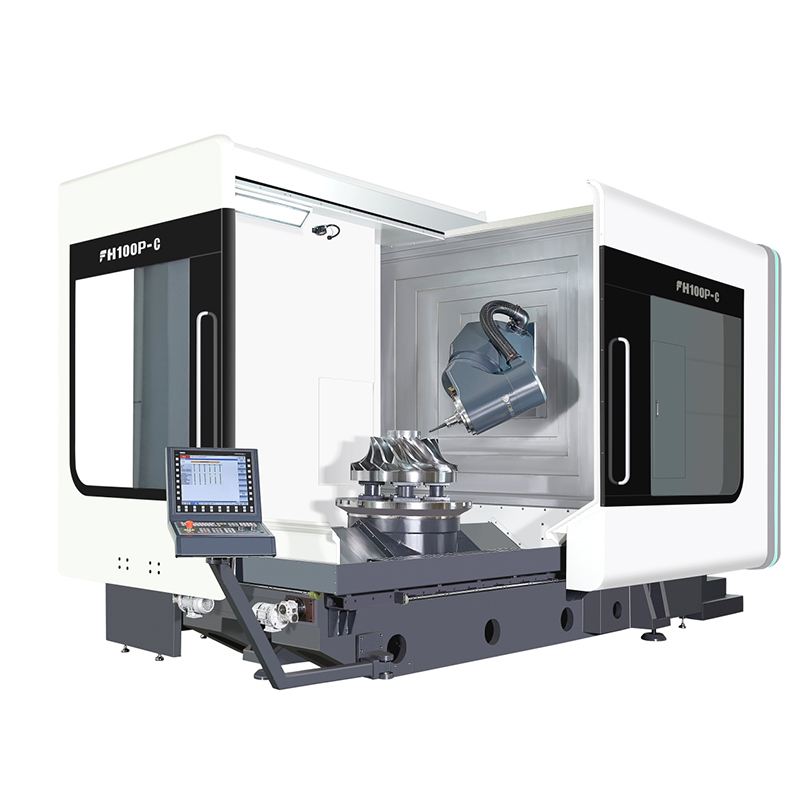

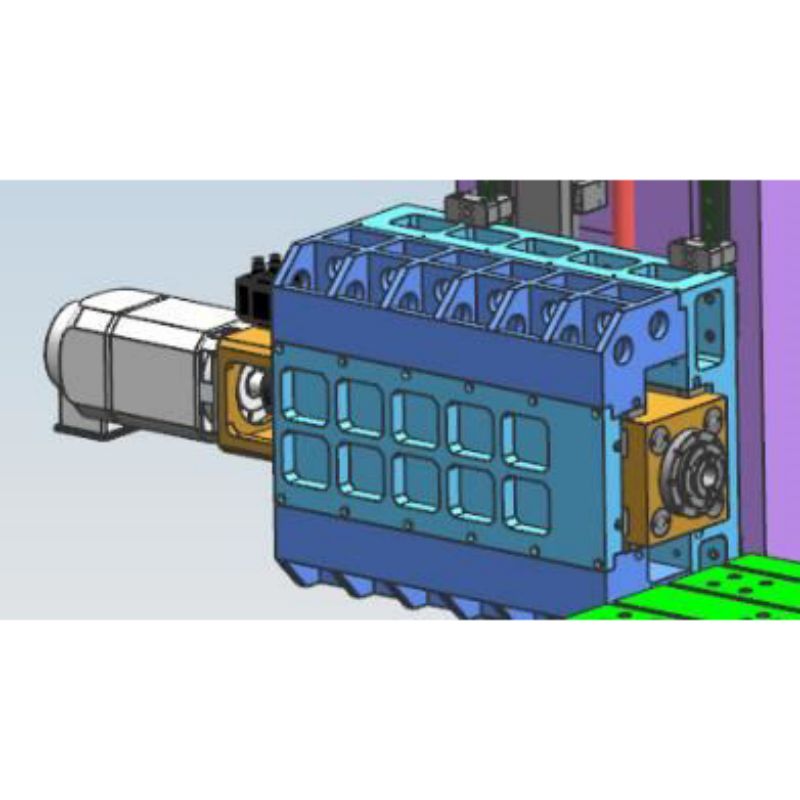

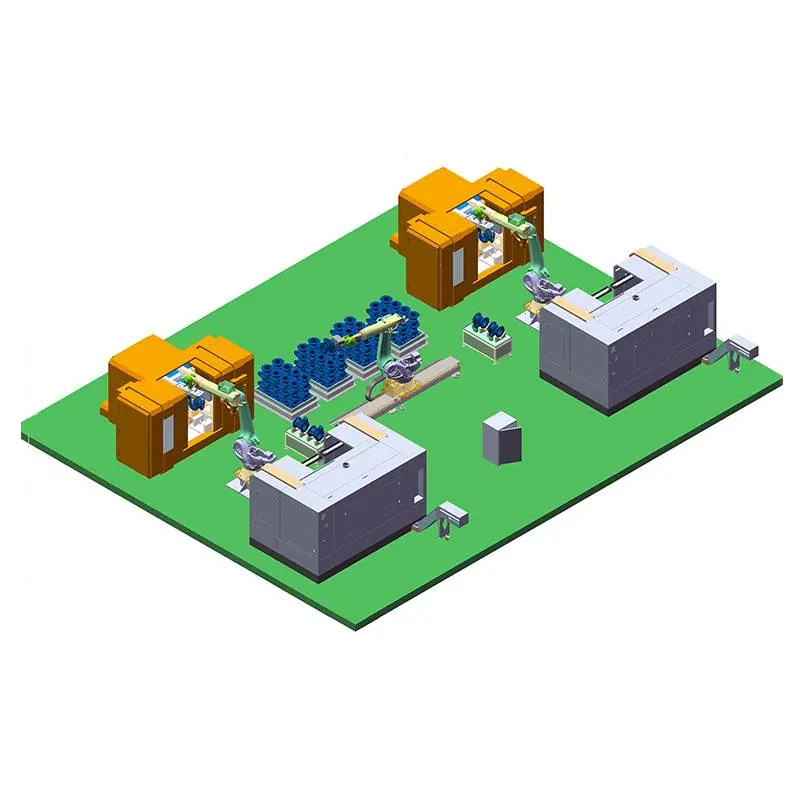

When it comes to precision machining, a double chuck lathe is an essential tool for manufacturers seeking reliability and efficiency in their production processes. In the current year, the market is witnessing several innovations and models that can significantly enhance productivity for global buyers. These advanced lathes offer features such as rigid construction, enhanced stability, and improved automation, which cater to a variety of machining needs. Choosing the right manufacturer is crucial for ensuring that your investment meets quality standards and enhances operational capabilities. Leading manufacturers are focusing on incorporating cutting-edge technology, ensuring that their double chuck lathes not only meet but exceed industry demands. With dependable engineering and robust after-sales support, companies can maintain seamless operations and minimize downtime. As the global market evolves, the importance of sourcing from reputable manufacturers cannot be overstated. Investing in a high-quality double chuck lathe can lead to significant improvements in production efficiency, product quality, and ultimately, profitability. By staying informed about the top players in the industry and their latest offerings, buyers can make well-informed decisions that align with their operational goals.

Double Chuck Lathe For the Current Year Manufacturers You Can Rely On

| Manufacturer | Model | Specifications | Features | Application |

|---|---|---|---|---|

| Manufacturer A | Model X1 | Max Diameter: 300mm | High Precision, Dual Spindle | Metalworking |

| Manufacturer B | Model Y2 | Max Diameter: 400mm | Robust Design, High Load Capacity | Woodworking |

| Manufacturer C | Model Z3 | Max Diameter: 250mm | CNC Capability, User-Friendly Control | Prototype Manufacturing |

| Manufacturer D | Model W4 | Max Diameter: 350mm | Compact Size, Versatile Usage | General Machining |

Related Products