CNC VTL Manufacturer in China - Precision Technology for Metalworking

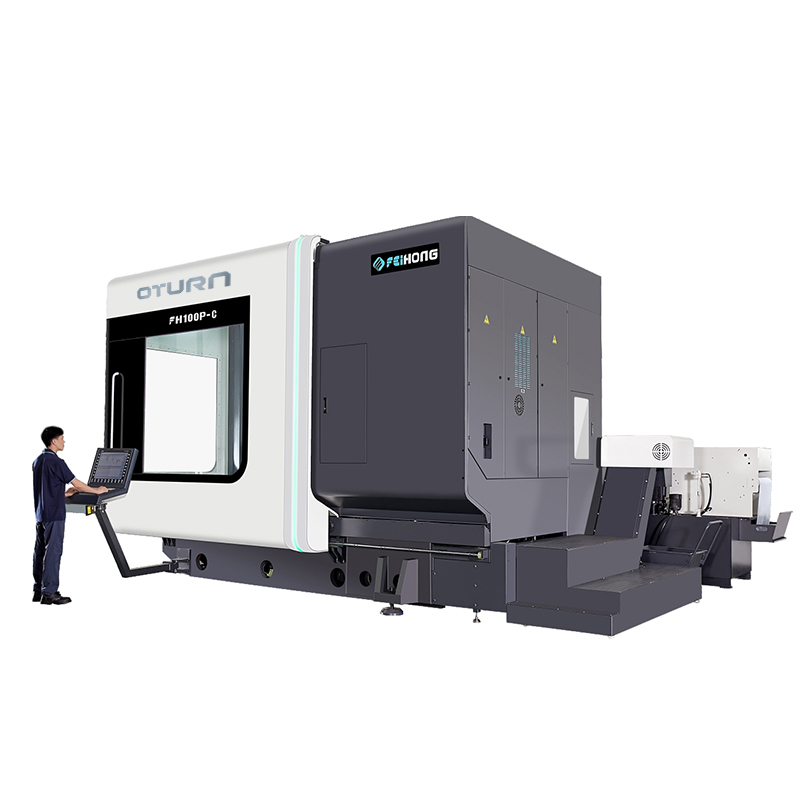

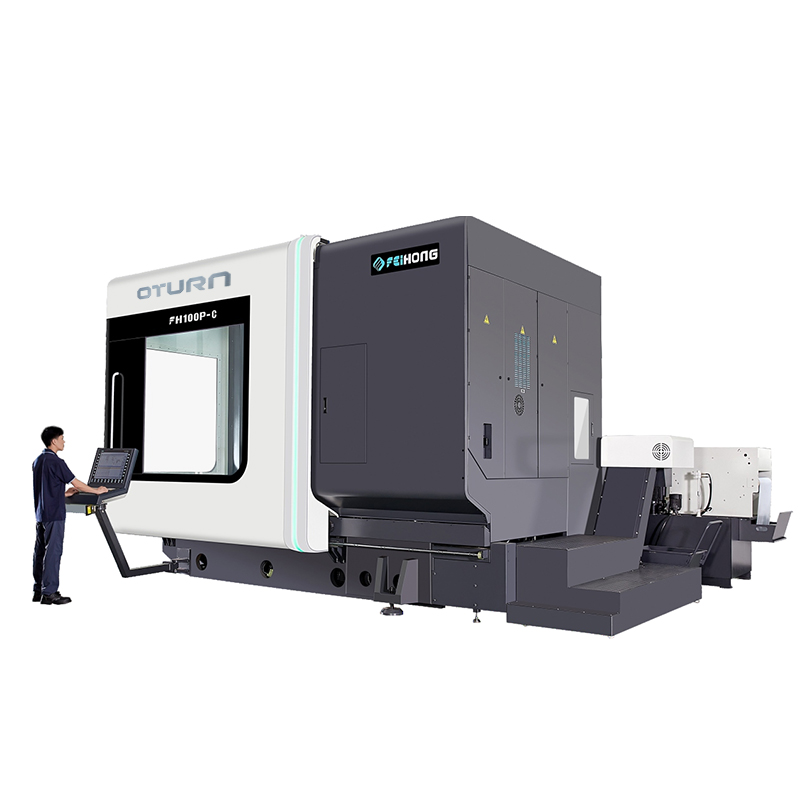

If you're in the market for a high-quality CNC VTL, you've come to the right place. Our CNC Vertical Turning Lathes are crafted to meet the demands of precision and efficiency, designed especially for manufacturers who are serious about quality. We know that finding a reliable manufacturer in China can be challenging, but our commitment to excellence sets us apart. Each machine is built with advanced technology, ensuring a smooth operation that enhances productivity. When I consider the needs of B2B purchasers, I understand that you need durability and accuracy. Our CNC VTLs not only deliver on performance but also come with excellent after-sales support. So, if you’re ready to elevate your manufacturing processes with reliable machinery, our CNC VTL stands out as the perfect choice. Let’s take your production capabilities to the next level!

Cnc Vtl Ahead of the Curve Your Trusted OEM Partner

In today's competitive landscape, finding a reliable partner for your CNC VTL (Vertical Turning Lathe) requirements is essential for maintaining efficiency and quality in manufacturing processes. As industries evolve, the demand for precision and innovation in machining technology has never been greater. This is where your search for a trusted OEM partner becomes crucial. With advanced engineering capabilities and a commitment to excellence, collaborating with a specialized manufacturer can enhance your production capabilities and streamline your operations. By investing in state-of-the-art CNC VTL solutions, manufacturers can significantly improve their productivity and achieve greater dimensional accuracy. These machines are designed to handle heavy workpieces while ensuring exceptional surface finishes, meeting the rigorous standards of various sectors including aerospace, automotive, and heavy machinery. When you partner with an established manufacturer, you gain access to not only top-tier machinery but also ongoing support and expertise that can help optimize your manufacturing processes and reduce downtime. Moreover, a reputable OEM partner understands the importance of customization and adaptability in meeting specific industry needs. By leveraging advanced technologies and innovative designs, such a partnership can provide tailored solutions that align with your operational goals. This proactive approach not only enhances efficiency but also fosters long-term growth and success in an ever-changing market. Together, you can stay ahead of the curve and meet the challenges of modern manufacturing with confidence.

Cnc Vtl Ahead of the Curve Your Trusted OEM Partner

| Model | Specifications | Capabilities | Material Compatibility | Applications |

|---|---|---|---|---|

| CNC VTL 1000 | Table Size: 1000mm, Max Load: 2000kg | Turning, Milling, Drilling | Steel, Aluminum, Brass | Automotive, Aerospace |

| CNC VTL 1500 | Table Size: 1500mm, Max Load: 3000kg | Turning, Grinding | Titanium, Steel | Marine, Oil & Gas |

| CNC VTL 2000 | Table Size: 2000mm, Max Load: 5000kg | Turning, Boring | Steel, Composite Materials | Heavy Industry, Railways |

Related Products