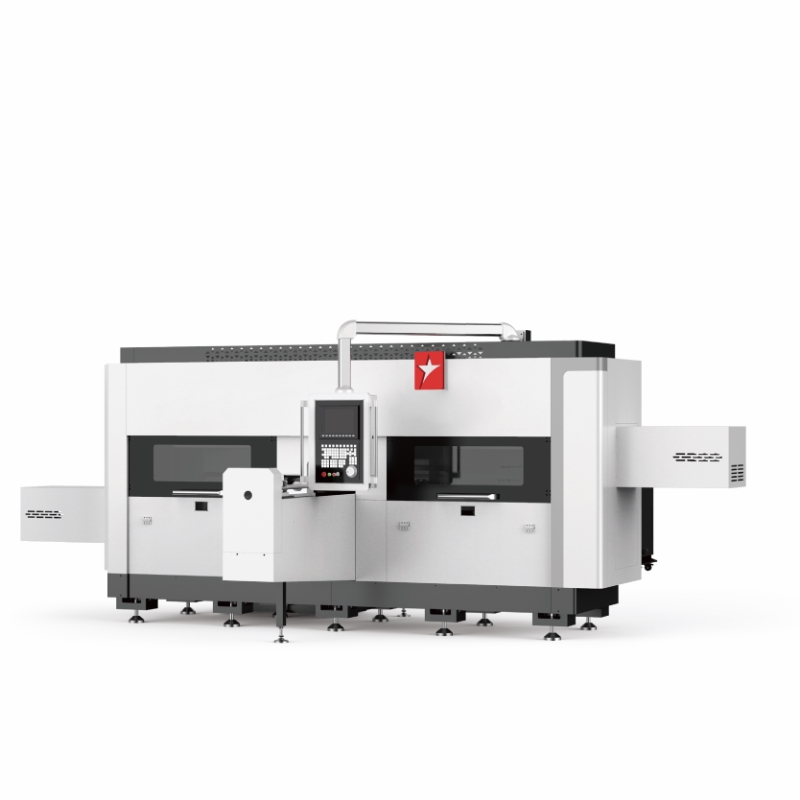

Affordable CNC Gear Hobbing Machine Price from Leading China Manufacturer

When it comes to finding a competitive **CNC gear hobbing machine price**, I understand how crucial it is for businesses to secure quality while staying within budget. Sourcing from a trusted **manufacturer in China** can significantly impact your production efficiency and cost-effectiveness. I’ve seen firsthand how our machines stand out with advanced technology and reliable performance, helping you produce precision gears effortlessly. Not only do they deliver high accuracy, but they also reduce production time, boosting your overall output. Our pricing strategies are tailored to provide the best value without compromising on quality. I’m here to support you in making an informed choice that aligns with your production needs and financial goals. Let me help you elevate your manufacturing process with our top-notch machines!

Cnc Gear Hobbing Machine Price Products Delivers Unmatched Quality

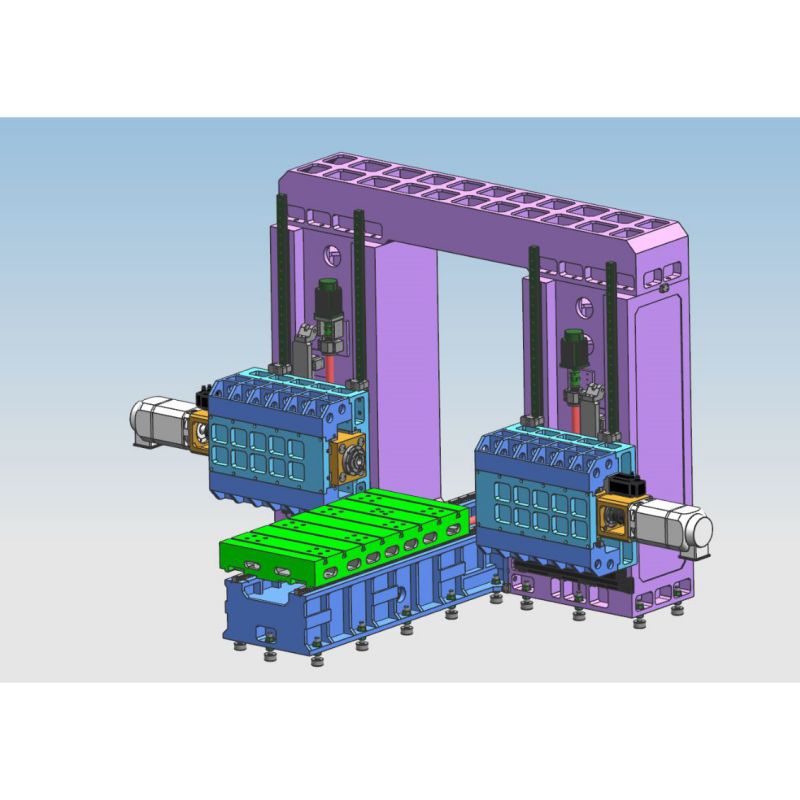

In the world of precision manufacturing, the efficiency and accuracy of gear production rely heavily on the quality of the machinery used. One of the standout solutions in this domain is the CNC gear hobbing machine, which has garnered attention from global procurement specialists for its advanced capabilities and competitive pricing. These machines are engineered to deliver unmatched quality in gear fabrication, ensuring that every component produced meets the highest industry standards. The CNC gear hobbing machines are designed to optimize production processes, featuring automated controls that enhance precision and reduce human error. This automation significantly streamlines the manufacturing workflow, leading to increased productivity and consistency in gear output. Additionally, with the current global demand for high-quality gears across various sectors, investing in a reliable CNC gear hobbing machine not only enhances operational efficiency but also positions companies to meet market demands effectively. Cost-effectiveness remains a key consideration for manufacturers seeking machinery that doesn't compromise on quality. The competitive pricing of CNC gear hobbing machines aligns perfectly with the needs of procurement professionals looking to maximize their return on investment. By choosing a machine that delivers superior performance without breaking the bank, businesses can maintain their competitive edge while ensuring the durability and reliability of their products. As global market dynamics continue to evolve, the adoption of such advanced machinery is a strategic move towards achieving sustainable growth and fostering innovation in gear manufacturing.

Cnc Gear Hobbing Machine Price Products Delivers Unmatched Quality

| Product Type | Specifications | Applications | Features | Quality Assurance |

|---|---|---|---|---|

| Horizontal Hobbing Machine | Max Gear Diameter: 200mm | Automotive Gears | High Precision, User-friendly | ISO 9001 Certified |

| Vertical Hobbing Machine | Max Gear Diameter: 300mm | Industrial Gears | Compact Design, High Efficiency | CE Marked |

| CNC Gear Hobbing Machine | Max Gear Diameter: 500mm | Aerospace Gears | Fully Automated, High Speed | 3-Year Warranty |

| Universal Hobbing Machine | Max Gear Diameter: 250mm | General Purpose | Versatile, Easy Setup | Rigorous Testing |

Related Products